Proton exchange membrane for fuel cell and preparation method thereof

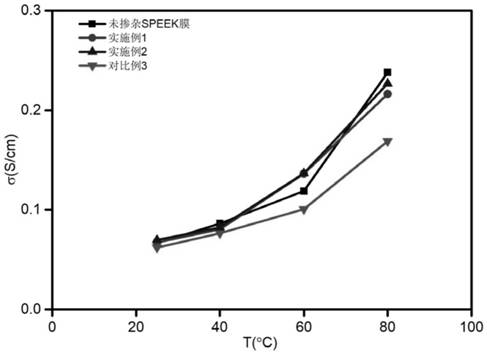

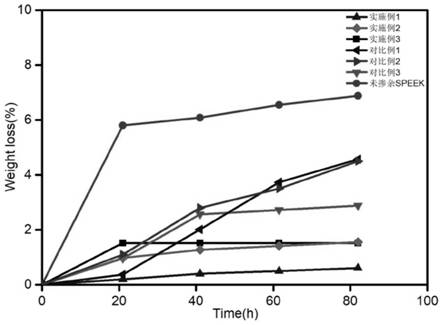

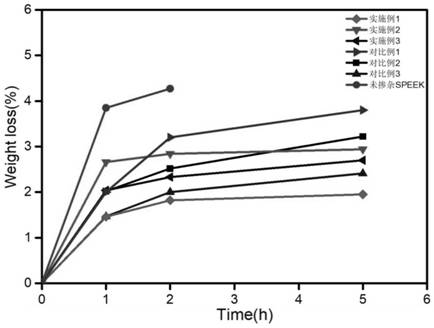

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve problems such as poor durability of proton exchange resins, and achieve excellent scavenging of free radicals, protection of proton membranes, and elimination of attacks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The preparation method of described modified material comprises the following steps:

[0064] Mix the inorganic material and polar solvent, heat to 60-150° C., then add the organosilane coupling agent, adjust the pH value, react for 1h-5h, and dry to obtain a solid.

[0065] Preferably, the polar solvent is selected from one or more of N,N-dimethylformamide (DMF), dimethylacetamide (DMAc), dimethylsulfoxide (DMSO) and toluene.

[0066] In particular, when using organosilanes containing amino groups to treat inorganic materials, it is preferable to add ammonia water dropwise to adjust the pH of the reaction solution to 8-11; , preferably dropwise adding glacial acetic acid to adjust the pH of the reaction solution to 3-6.

[0067] When the organosilane coupling agent contains a mercapto functional group, the preparation method of the modified material also includes:

[0068] Add an oxidizing agent to the solid, raise the temperature to 60-90°C, and stir for 0.5h-5h to ...

Embodiment 1

[0078] The average particle size of the cerium oxide in Example 1 is about 30nm, and the surface contains about 3% of hydroxyl groups, about 96% of +4-valent cerium and about 4% of +3-valent cerium on the surface.

Embodiment 2

[0079] The average particle size of the nickel oxide in Example 2 is about 60nm, and the surface contains about 5% of hydroxyl groups in mole fraction, about 92% of +3-valent nickel and about 8% of +2-valent nickel in mole fraction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com