Motor control method based on single Hall sensor

A hall sensor, motor control technology, applied in the direction of electronic commutator, etc., can solve the problems of unreliable, motor control failure, no brushless motor, etc., to ensure reliable operation, ensure reliable operation, and occupy a small space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

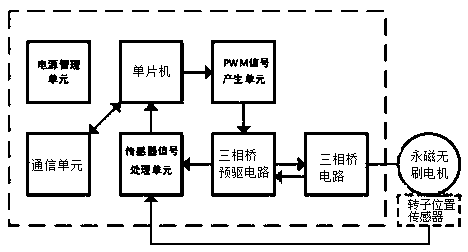

[0029] According to a motor control method based on a single Hall sensor according to an embodiment of the present invention, the single Hall sensor is used to detect the position of the motor rotor, and the motor control method based on a single Hall sensor includes the following steps:

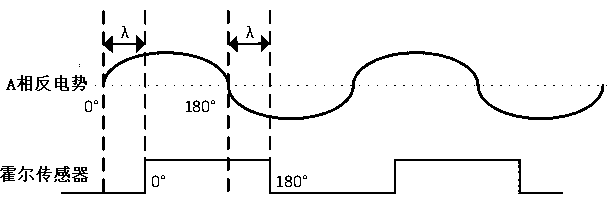

[0030] a. Measure the phase difference λ between any opposite potential of the motor and the output signal of a single Hall sensor;

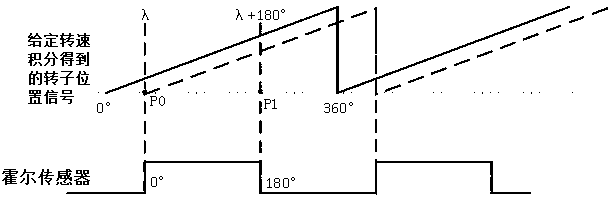

[0031] b. Given the speed Vn of the motor, output a voltage or current signal to the motor to start the motor, and obtain the theoretical position Pn of the rotor by integrating the given speed Vn;

[0032] c. When the rising edge of the output signal of a single Hall sensor is detected, use λ to correct the theoretical rotor position obtained by integration, so that the theoretical value P0 of the rotor position at the moment when the rising edge is detected is equal to λ, and P0 is used as Based on the subsequent rotor position integral calculation;

[0033...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com