Drilling and milling machining center

A machining center, drilling and milling technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of low position accuracy of the cutting spindle 23, difficulty in ensuring the alignment of tooth peaks and tooth valleys, and the influence of natural processing accuracy, etc. problem, to achieve the effect of ensuring timely combination and separation, simplifying the structure, and eliminating positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

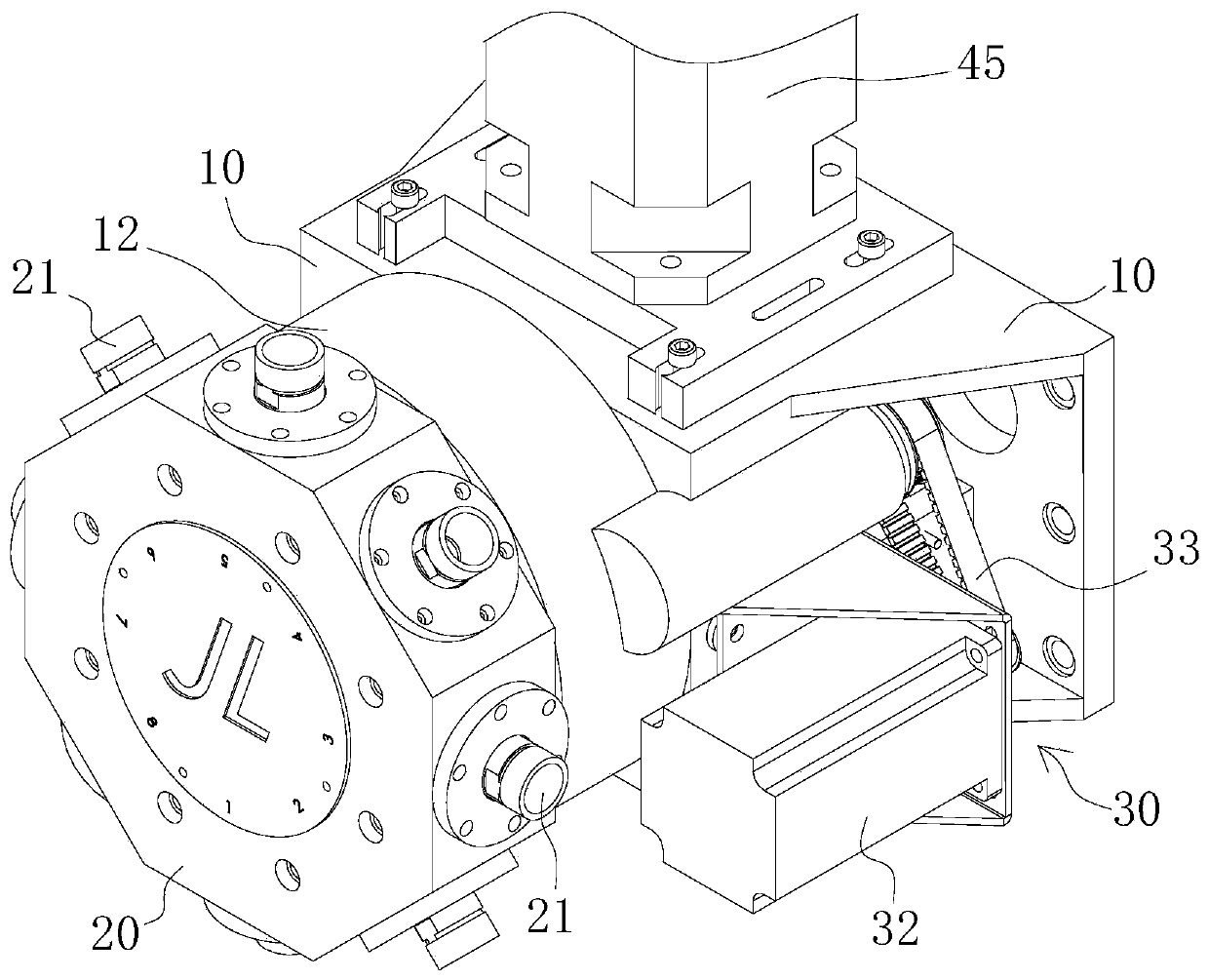

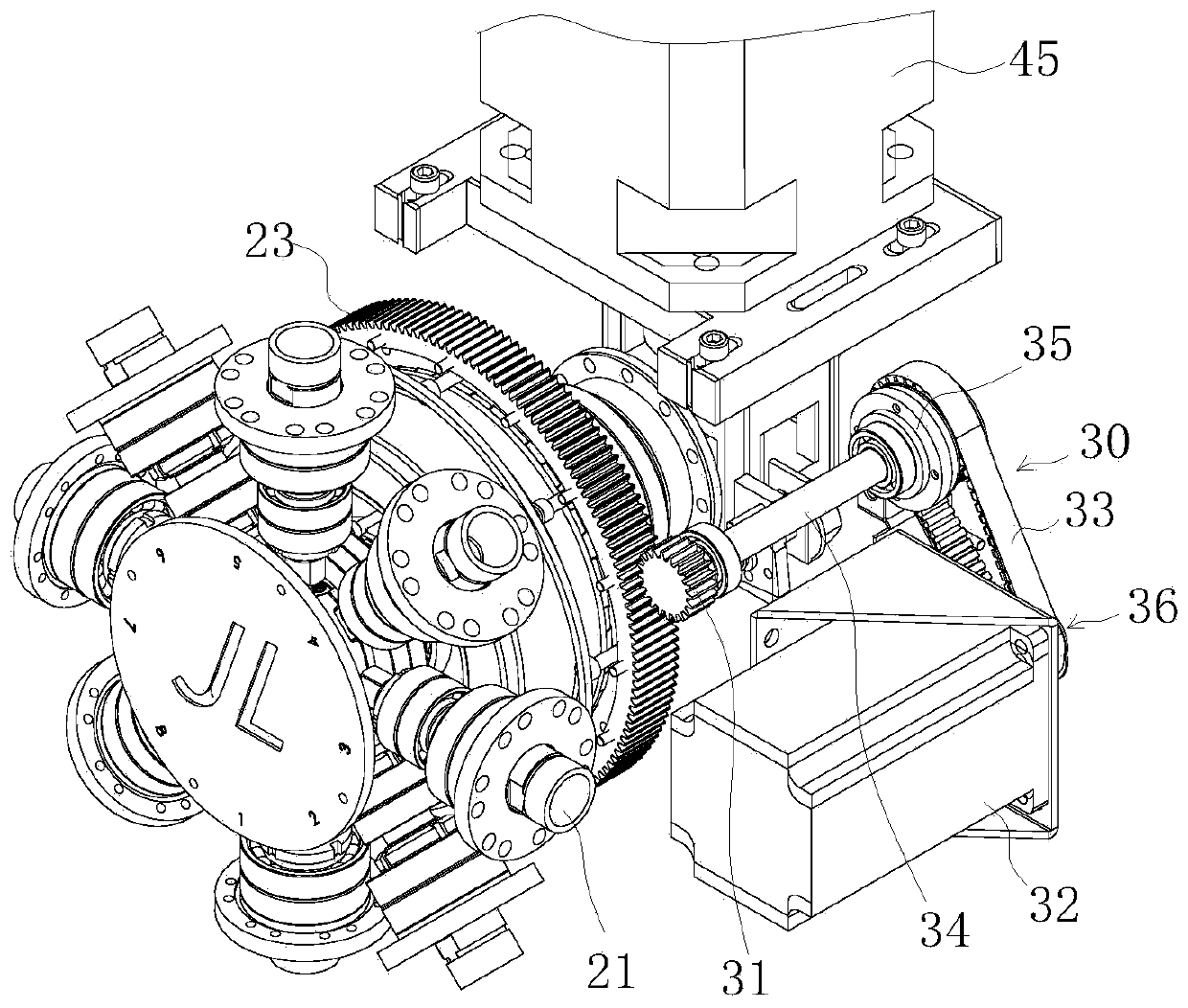

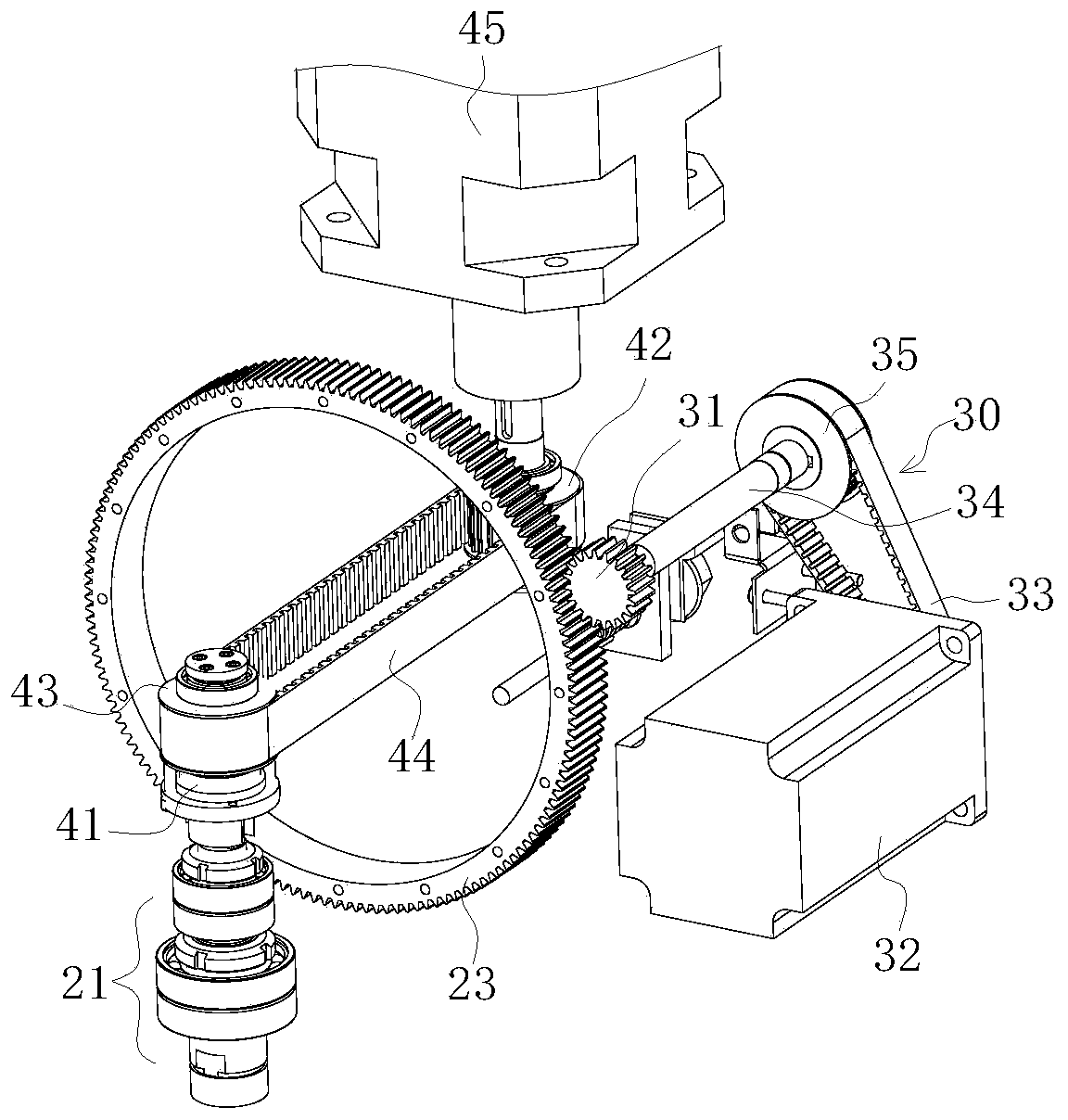

[0018] Such as figure 1 , 2 As shown in , 3 and 4, a drilling and milling machining center is provided with a turret 20 on the chassis 10 arranged on the frame, and the turret 20 and the chassis 10 form a circumferential rotation and axial limit cooperation, and the first drive unit 30 drives the turret 20 to rotate relative to the chassis 10 along the axis of rotation of the turret 20; this scheme limits the axial displacement of the turret 20, reduces the position error in the direction of one degree of freedom, and provides an axially determined position for the positioning of the tool. Locate the reference, and realize the conversion of the tool change position through the rotation of the turret 20 around its axis of rotation.

[0019] A locking mechanism is provided between the turret 20 and the chassis 10. When the locking mechanism is unlocked, the turret 20 rotates relative to the chassis 10 along the axis of rotation of the turret 20. When the locking mechanism is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com