Kitchen waste percolate treatment device and using method thereof

A technology of food waste and treatment equipment, which is applied in the field of food waste leachate treatment equipment, can solve the problems of high content of food waste leachate and cannot be effectively used, and achieve the goal of improving utilization rate, efficiency, and area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

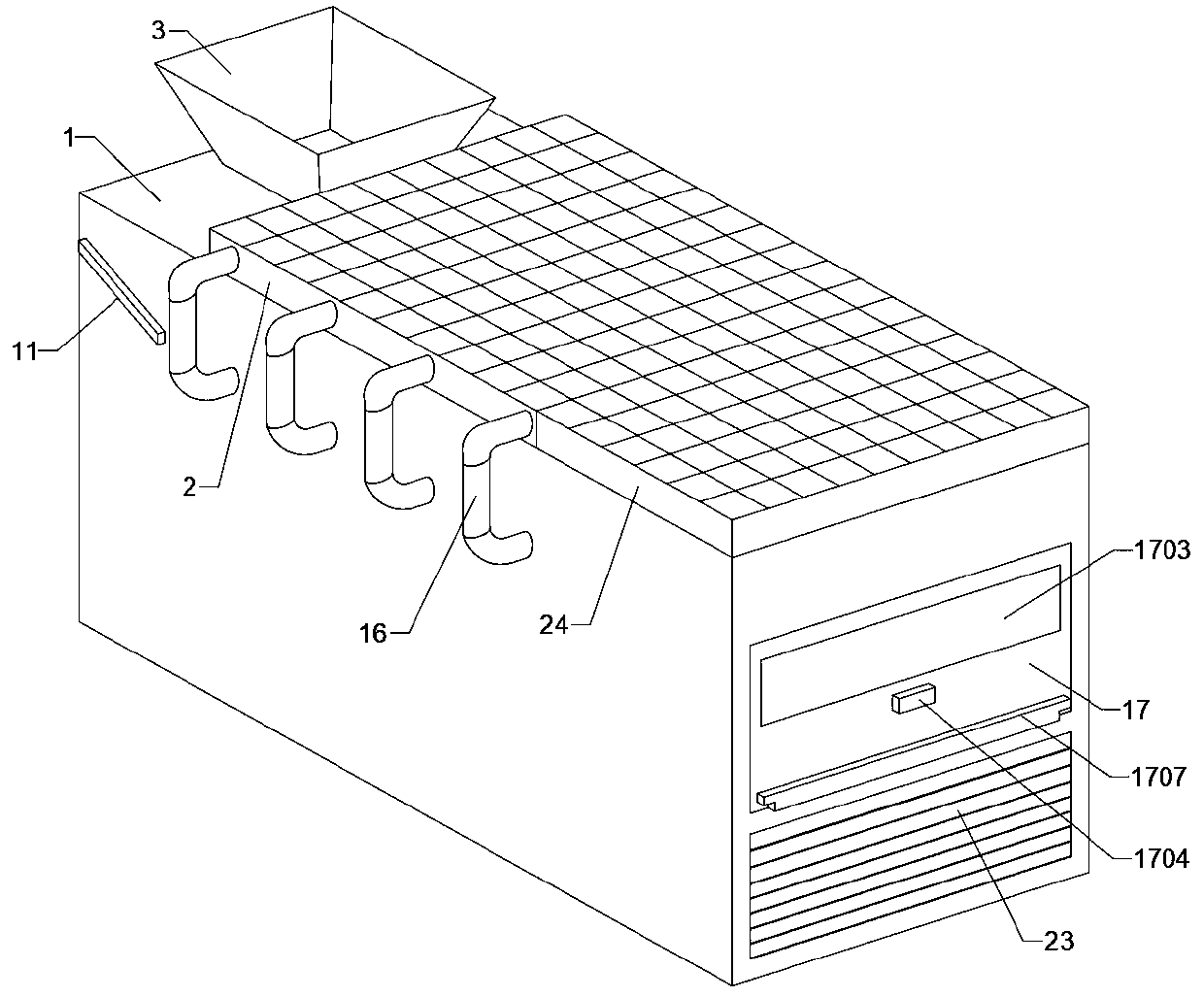

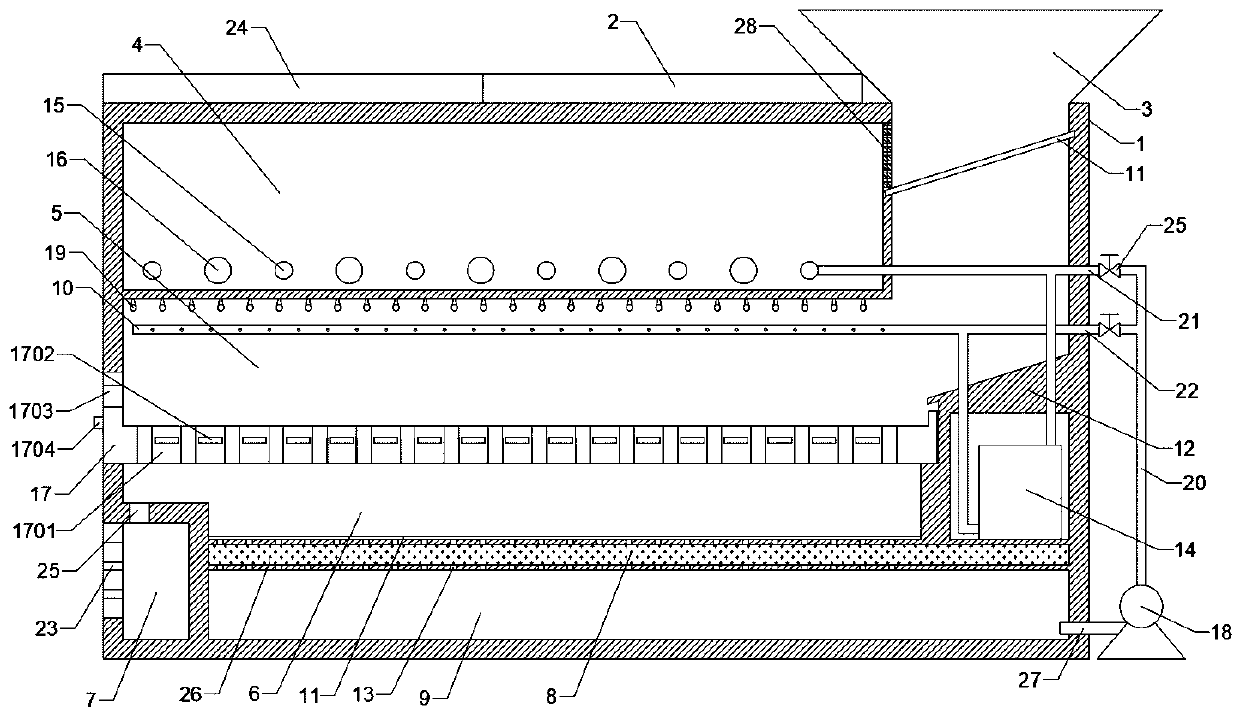

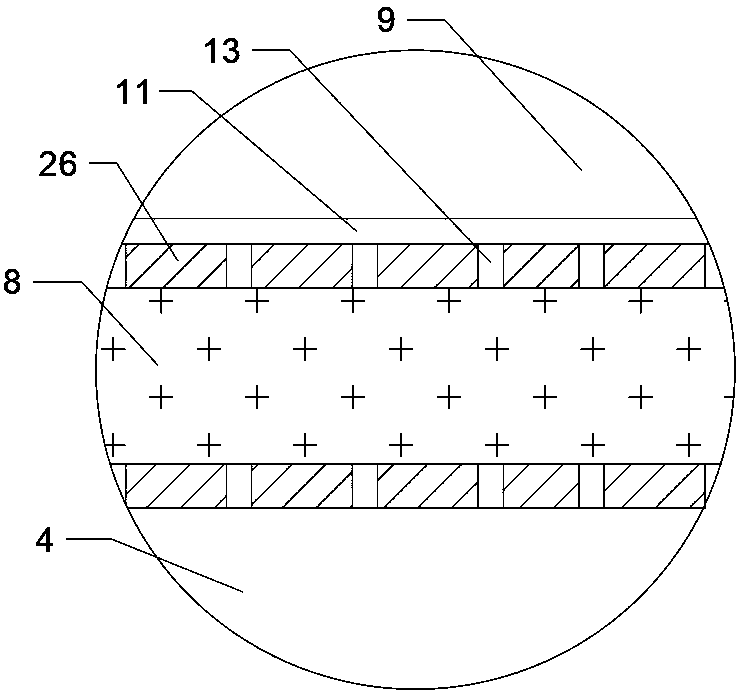

[0054] Such as Figure 1~2 The shown kitchen waste leachate treatment device includes a body 1, a solar collector 2 arranged on the top of the body 1, a material inlet 3 and a solar panel 24; the material inlet 3 is arranged at one end of the top of the body 1 , and the other end is respectively provided with adjacent solar collectors 2 and solar panels 24; the inside of the body 1 is respectively a waste liquid tank 4, a biological treatment layer 5, a biochemical purification layer 6 and a purification liquid storage tank from top to bottom. Slot 9, as in figure 2 shown.

[0055] The waste liquid tank 4 communicates with the lower channel of the material inlet 3 through the filter screen 28; the bottom of the waste liquid tank 4 is provided with a water filter pipe 15 and a heat pipe 16, and the water filter pipe 15 is connected to the water inlet of the evaporator 14 and the cleaning pipe 20 respectively. First branch pipe 21; heat pipe 16 is connected with solar heat co...

Embodiment 2

[0068] Compared with Example 1, the difference of the kitchen waste leachate treatment device of this example is:

[0069] Described cultivation dish 17 is as Figure 5-7 As shown, the air intake groove 1701 is provided with an air inlet 1702 through the plate body, a layer of grid 1705 is provided in the culture plate 17, and a removable inserting plate 1707 is provided at the bottom.

[0070] The grid 1705 can make the worm sand in the breeding tray 17 fluffy, so that the air can enter the worm sand inside through the air inlet 1702, and improve the breeding efficiency of the black soldier fly; Drops in sand filling sieve 1706.

[0071] In the method of using the device in this embodiment, the method for separating insect sand and black soldier flies in step S4 is: after pulling out the insertion plate 1707 at the bottom of the culture tray 17, shake the culture tray 17 so that the insect sand in the tray passes through the sieve holes 1706 to drop Fall into the biochemica...

Embodiment 3

[0073] Compared with Embodiment 2, the difference of the kitchen waste leachate treatment device of this embodiment is:

[0074] The biological treatment layer 5 is as Figure 8 As shown, the left and right are divided into a breeding area and a separation area, which are separated by a partition plate 34 in the middle, and the separation area is provided with a separation drum 31; The end is arranged on the lower part of the inclined plane of the storage bin 12, the discharge end is arranged on the lower part of the partition plate 34 and is located on the upper part of the culture plate 17; the wall of the separation drum 8 is evenly distributed with through holes 33, and the rotating shaft is provided with helical blades along its axial direction. 32 ; the motor 30 is arranged in the upper part of the storage bin 12 .

[0075] The bottom of the separation roller 31 is also provided with a second evaporator 36, which is arranged on the lower part of the culture tray 17 near...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com