Hyperbranched polyvinyl acetate and its high stability writing ink

A polyvinyl acetate and vinyl acetate technology, which is used in inks, household appliances, applications, etc., can solve the problems of not involving the application of hyperbranched polyvinyl acetate, affecting the quality of emulsified ink, and increasing the viscosity of ink, and achieves excellent water solubility. Properties and emulsifying properties, good writing performance and line appearance, high thixotropic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

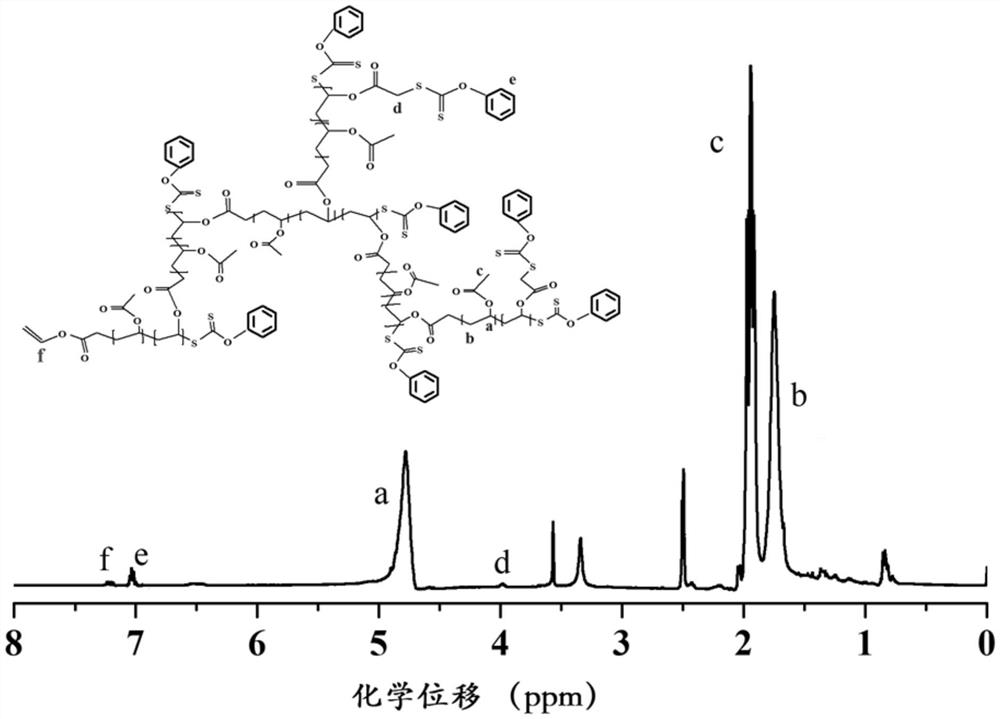

[0043] The synthesis of hyperbranched polyvinyl acetate, step is as follows:

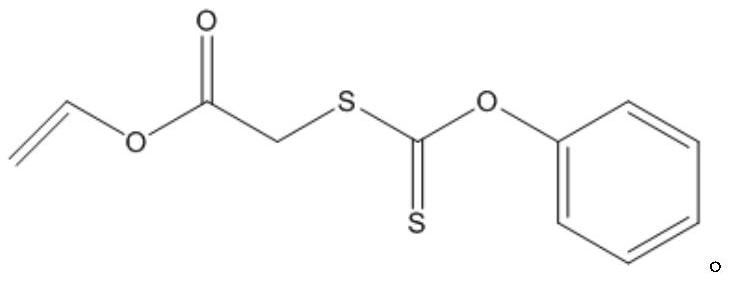

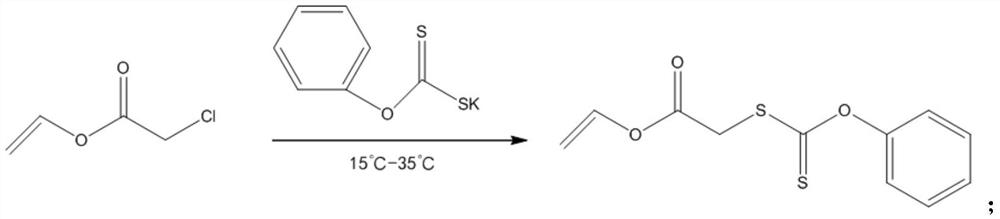

[0044] (1) Synthesis of RAFT reagent PCTVA: Add 300mL of solvent dimethylformamide into the reaction kettle, add 100g of potassium phenoxyxanthate while stirring, fully dissolve and mix well, slowly add 80g of vinyl chloroacetate dropwise, mix The solution was stirred and reacted at room temperature for 3-5 hours. After separation and purification, 110 g of a yellow-green product was obtained, and the calculated yield was 63%. The purity of the obtained product can reach 99% through HPLC detection.

[0045] (2) 500g of monomer vinyl acetate (Vac), 50g of initiator azobisisobutyronitrile (AIBN), 50g of PCTVA and 500mL of solvent (1,4-dioxane) were added successively in the reactor. (40-70° C.) to carry out the reaction for 5-8 hours. After the reaction finishes, separation promptly obtains hyperbranched polyvinyl acetate 540g, and product is carried out GPC measurement, and its molecular weight dis...

Embodiment 2

[0047] Using self-made hyperbranched polyvinyl acetate as polymer resin additive, configure black writing ink.

[0048] (1) Heat 60 grams of ethylene glycol phenyl ether solvent to 80-95 degrees Celsius, gradually add 20 grams of black dye solvent black 209 to it and stir until completely dissolved, add 1 gram of stabilizer Tween after slightly cooling and stir Evenly, make dye compound solution A.

[0049] (2) 45 grams of deionized water and 20 grams of diethylene glycol ether were mixed, heated and stirred evenly to obtain solvent compound solution B.

[0050](3) Slowly add the solvent compound solution B into the dye compound solution A, add while stirring, control the stirring speed at 600-900 rpm, stir for 30 minutes, continue to accelerate the stirring for 60-80 minutes after adding all of it, The rotating speed is 3000 rpm, and the system temperature is maintained at 60 degrees Celsius to prepare emulsified alcohol solution C.

[0051] (4) Take 18 grams of polyvinyl a...

Embodiment 3

[0054] Using self-made hyperbranched polyvinyl acetate as an important polymer resin additive, a blue writing ink is configured.

[0055] (1) Heating 60 grams of phenylethyl alcohol and ethylene glycol phenyl ether solvent (35 grams of phenylethyl alcohol, 25 grams of ethylene glycol phenyl ether) to 80-95 degrees Celsius, gradually adding 18 grams of blue dye solvent Blue No. 38 and Stir evenly until completely dissolved, then add 1 g of stabilizer Tween after slightly cooling down and stir evenly to make dye compound solution A.

[0056] (2) 45 grams of deionized water and 22 grams of diethylene glycol ether were mixed, heated and stirred evenly to obtain solvent compound solution B.

[0057] (3) Slowly add the solvent compound solution B into the dye compound solution A, add while stirring, control the stirring speed at 600-900 rpm, stir for 30 minutes, continue to accelerate the stirring for 60-80 minutes after adding all of it, The rotating speed is 3000 rpm, and the sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| photostability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com