Extra-black high-gloss wear-resistant polyamide resin, preparation method and application thereof

A polyamide resin, high gloss technology, applied in the field of polymer materials, can solve problems such as difficult to achieve, and achieve the effects of good wear resistance, good surface gloss and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

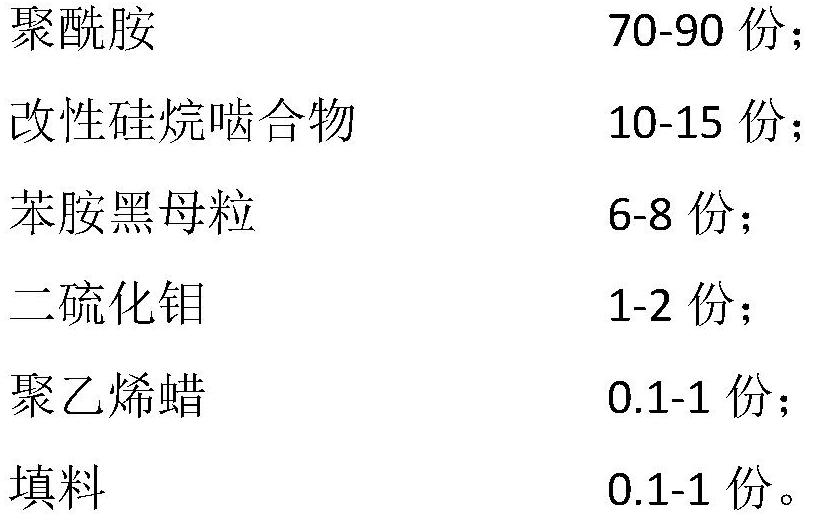

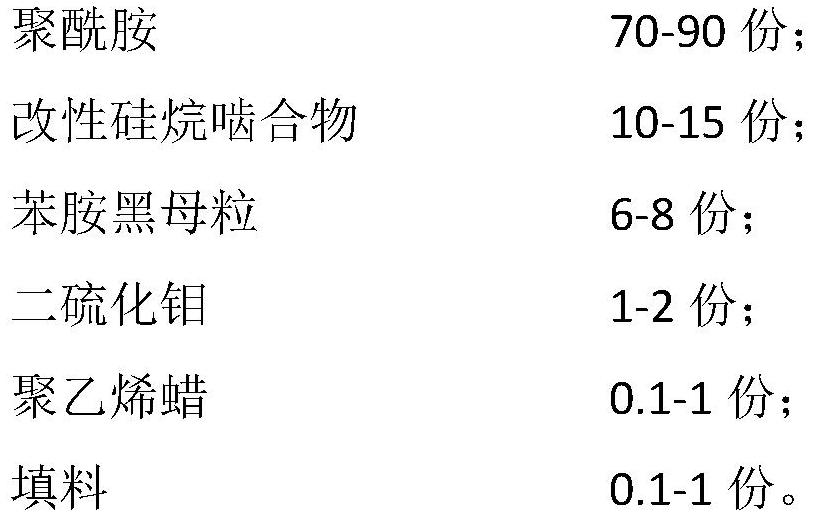

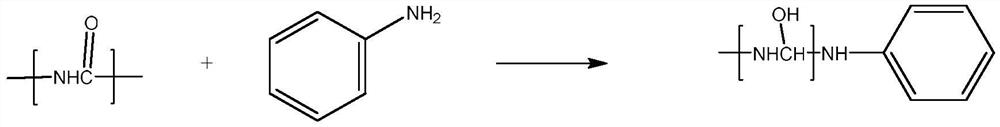

[0060] The preparation method of the extra-black high-gloss wear-resistant polyamide resin of the present invention comprises the following steps:

[0061] (1), prepare nigrosine master batch;

[0062] (2), mixing polyamide, molybdenum disulfide, nigrosine master batch, polyethylene wax, modified silane meshing material and filler in a mixer to obtain a mixture;

[0063] (3), adding the mixture into a twin-screw extruder for extrusion, and dicing to obtain an extra-black high-gloss wear-resistant polyamide resin.

[0064] Wherein, in step (1), nigrosine master batch is obtained by mixing 85-90wt% nylon 6, 9-13wt% oil-soluble nigrosine and 1-2wt% dispersant for 5-8min and extruding, and the dispersant is vinyl Distearate. The extrusion process is as follows: the temperature of the first zone is 180-220°C, the temperature of the second zone is 190-230°C, the temperature of the third zone is 200-250°C, the temperature of the fourth zone is 200-250°C, and the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com