Method for preparing refrigerated instant black glutinous rice

A production method and technology for glutinous rice, which are applied to the functions of food ingredients, the food ingredients as gelling agents, and the food ingredients as antioxidants, etc., can solve the problems of easy discoloration, long time consumption of glutinous rice, and inability to achieve jet black, etc. Achieve the effect of increasing human lysine intake, improving color stability, and reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

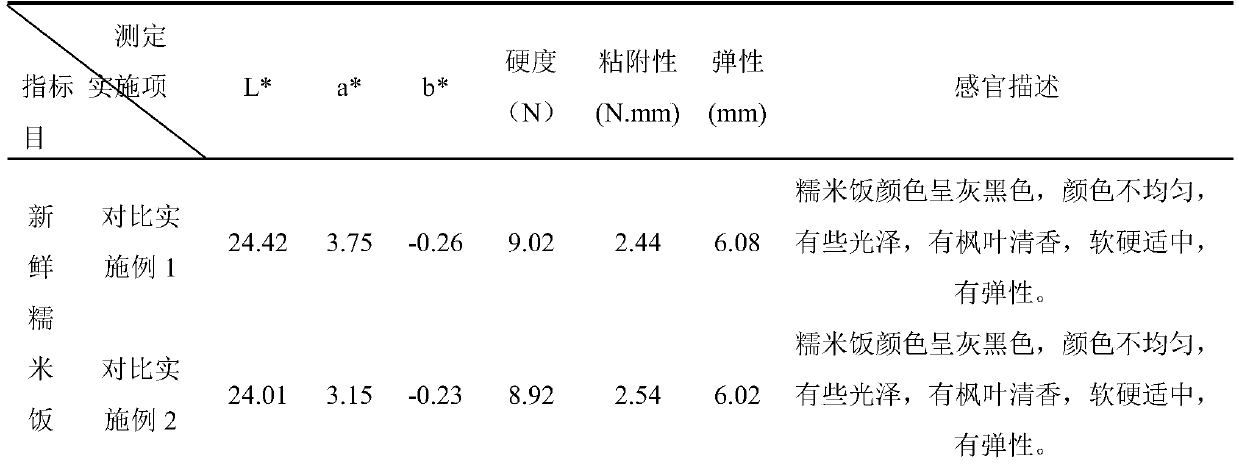

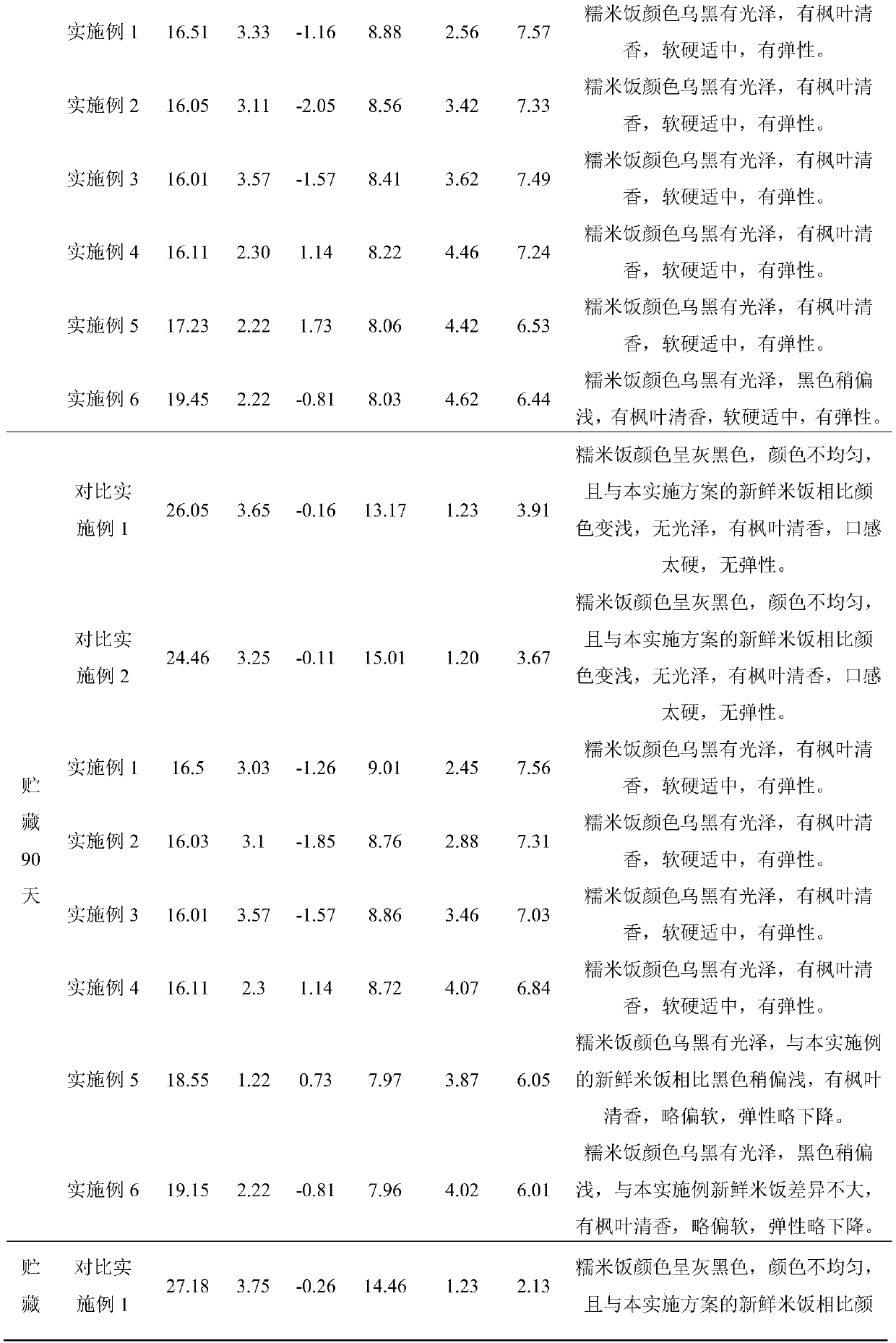

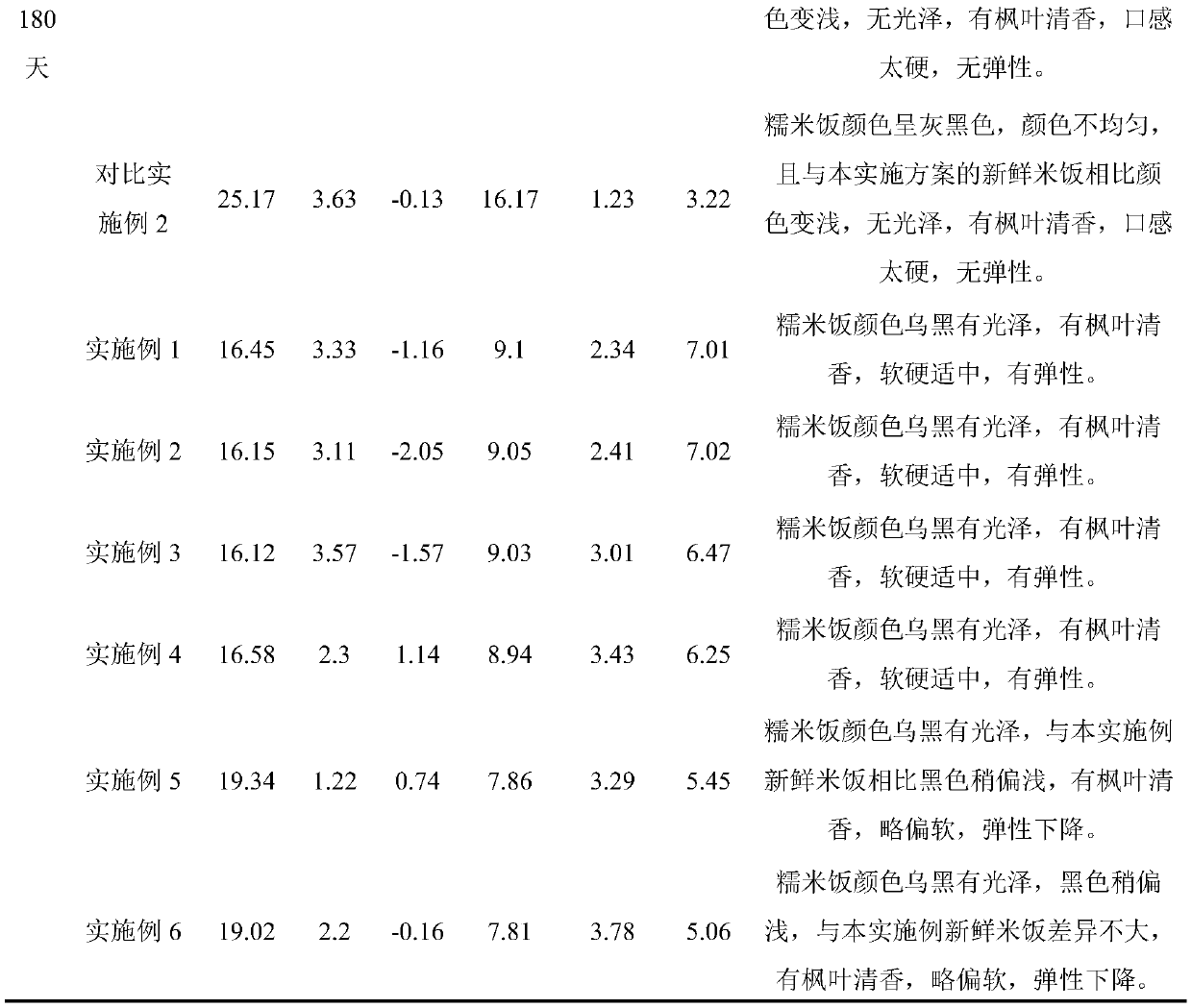

Examples

Embodiment 1

[0039] A method for making black glutinous rice using maple leaves and glutinous rice as main raw materials, comprising the following steps:

[0040] (1) Wash 100 parts of fresh maple leaves, cut them into 0.5 cm long with a knife, mash them, add 300 parts of water, soak at 10°C for 10 hours, filter, take the filtrate, heat it to 90°C, and cool it to 45°C;

[0041] (2) Rinse the fresh dry glutinous rice with flowing water for 0.5 minutes, and immediately rinse 50 parts with the maple leaf extract in step (1), then wash 50 parts of glutinous rice, 2 parts of calcium chloride; 2 parts of iron and 1 part of ferric citrate; put them together into the remaining 250 parts of the extract in step (1) and soak at a constant temperature of 40°C for 6 hours, stirring once every 0.5 hours;

[0042] (3) Add 1.0 parts of α-amylase to the soaking solution in step (2) and stir for 15 minutes, filter to obtain soaked black glutinous rice;

[0043] (4) Add 1 part of apple polyphenol, 0.01 part...

Embodiment 2

[0046] A method for making black glutinous rice using maple leaves and glutinous rice as main raw materials, comprising the following steps:

[0047] (1) Wash 100 parts of fresh maple leaves, cut them into 0.5 cm lengths with a knife, mash them, add 300 parts of water, soak at 20°C for 8 hours, filter, take the filtrate, heat it to 90°C, and cool it to 45°C;

[0048] (2) Rinse fresh dry glutinous rice with running water for 0.5 minutes, then immediately rinse 50 parts with the maple leaf extract in step (1), then wash 50 parts of glutinous rice, 2 parts of calcium lactate, and ferrous lactate Put 2 parts, 1 part of ferrous gluconate, etc. into the remaining 250 parts of the extract in step (1) and soak at a constant temperature of 43°C for 5 hours, stirring once every 0.5 hours;

[0049] (3) Add 1.0 parts of β-amylase to the soaking solution in step (2) and stir for 10 minutes, filter to obtain soaked black glutinous rice;

[0050] (4) 2 parts of apple polyphenols, 0.01 part ...

Embodiment 3

[0053] A method for making black glutinous rice using maple leaves and glutinous rice as main raw materials, comprising the following steps:

[0054] (1) Wash 100 parts of fresh maple leaves, cut them into 0.5 cm lengths with a knife, mash them, add 300 parts of water, soak at 30°C for 7 hours, filter, take the filtrate, heat it to 80°C, and cool it to 45°C;

[0055] (2) Rinse fresh dry glutinous rice with running water for 0.8 minutes, and immediately rinse 50 parts with the maple leaf extract in step (1), then wash 50 parts of glutinous rice, 4 parts of calcium lactate; ferrous lactate 4 parts; put them together into the remaining 250 parts of the extract in step (1) and soak at a constant temperature of 45°C for 4 hours, stirring once every 0.5 hours;

[0056] (3) Add 1.5 parts of β-amylase to the soaking solution in step (2) and stir for 10 minutes, filter to obtain soaked black glutinous rice;

[0057] (4) Add 4 parts of apple polyphenols, 0.03 parts of polylysine, 0.1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com