Silver-plated part blackening treatment agent and silver-plated chemical blackening treatment method

A treatment method and blackening agent technology, applied in the coating process of metal materials, etc., can solve the problems of long blackening time, high blackening temperature, and no beneficial function, and achieve stable chemical properties, uniform surface, and smooth appearance. The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

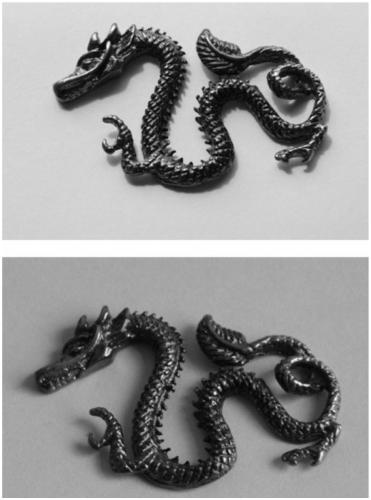

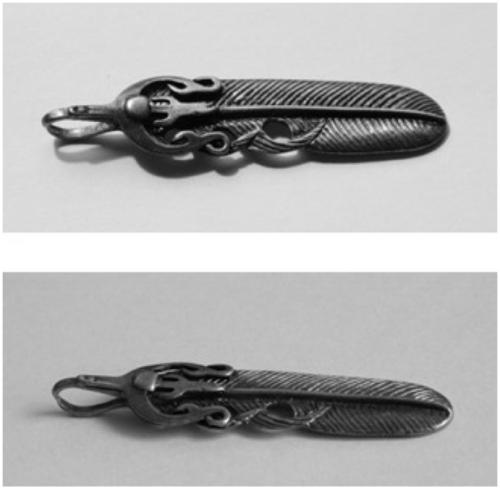

Image

Examples

Embodiment 1

[0025] The main blackening agent is linear dodecyl mercapto (HS-(CH 2 ) 11 -CH 3 ), the content is 0.6molL -1 . The auxiliary blackening agent is p-methylthiophenol (also known as 4-methylthiophenol or 4-mercaptotoluene), the content is 0.02molL -1 . Surfactant is OP emulsifier content is respectively 0.1g / L. The solvent is 95% ethanol and 5% water. The blackening time is 15 minutes, and the temperature of the blackening solution is 40°C. The samples were aged for 24 hours after blackening.

Embodiment 2

[0027] The main blackening agent is linear tetradecyl mercaptool (HS-(CH 2 ) 13 -CH 3 ), the content is 0.8molL -1 . The auxiliary blackening agent is 4-mercaptobenzoic acid, the content is 0.05molL -1 . Surfactant is Triton 0.01g / L and OP emulsifier 0.1g / L. The solvent is 98% ethanol and 2% water. The blackening time is 20 minutes, and the temperature of the blackening solution is 50°C. The samples were aged for 48 hours after blackening.

Embodiment 3

[0029] The main blackening agent is straight-chain hexadecyl mercaptool (HS-(CH 2 ) 15 -CH 3 ), the content is 0.5molL -1 . The auxiliary blackening agent is 4-mercaptoaniline, the content is 0.08molL -1 . Surfactant is 0.1g / L OP emulsifier and 0.1g / L alkylphenol polyoxyethylene ether. The solvent is 98% ethanol and 2% water. The blackening time is 10 minutes, and the temperature of the blackening solution is 35°C. The samples were aged for 24 hours after blackening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com