Vacuum freeze-dried beef jerky and method for increasing drying rate thereof

A vacuum freeze-drying and beef jerky technology, applied in food drying, food science and other directions, can solve the problems of long drying time and high processing cost, and achieve the effect of good chewiness, wide range and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

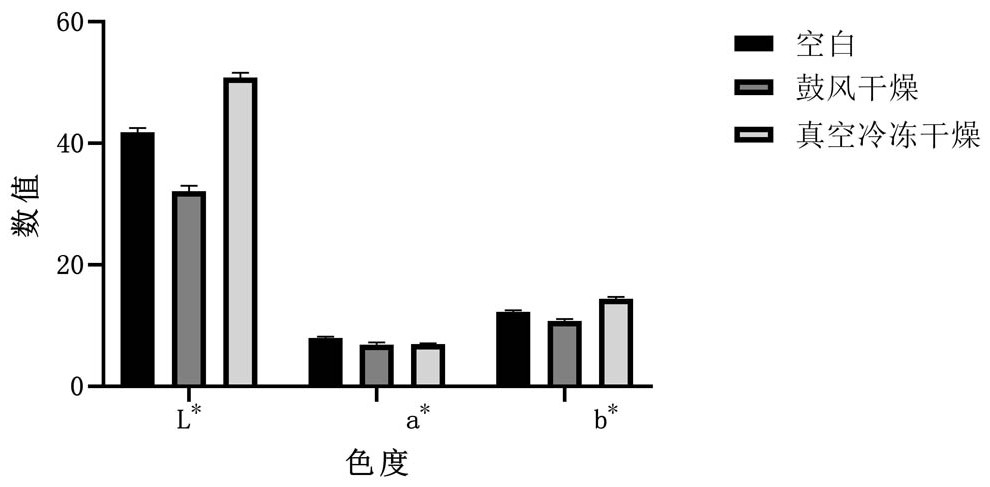

[0029] The present embodiment provides a kind of vacuum freeze-dried beef jerky, and the method for accelerating the drying rate of beef jerky comprises the following steps:

[0030] 1) Cut the beef into beef slices, cut into 1-2cm thick, 2-3cm wide, 4-5cm long thin slices, which is convenient for subsequent processing.

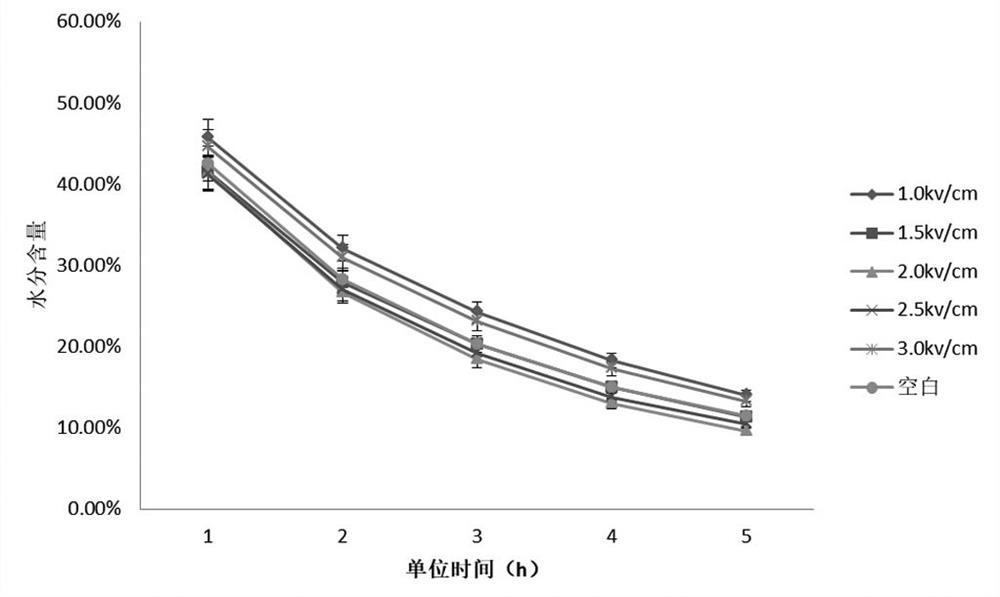

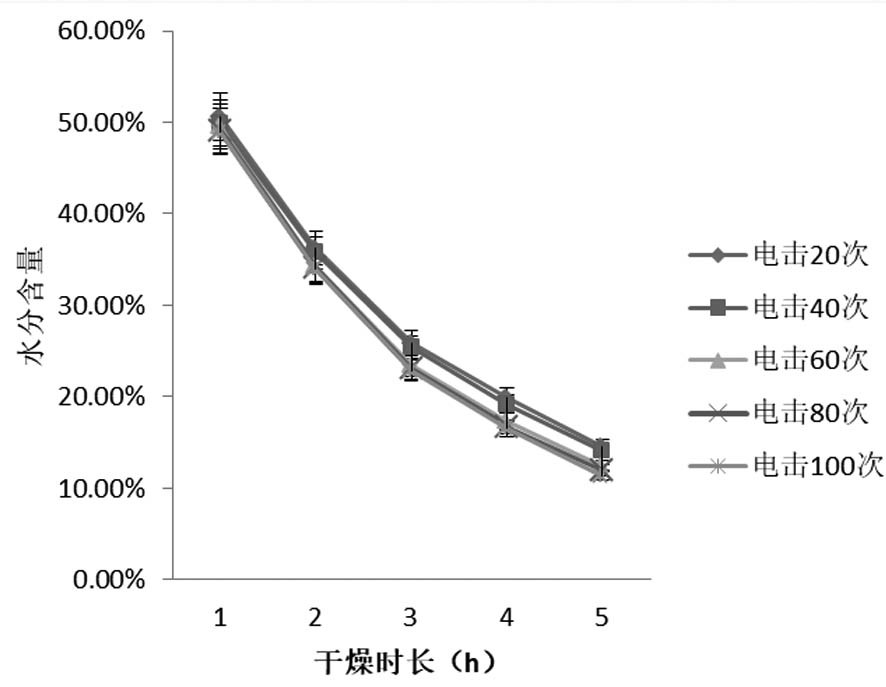

[0031] 2) Put the beef slices obtained in step 1) into a high-voltage transient pulse electric field device, shock 200 times at an electric field strength of 2.0kV / cm, and apply ice packs to cool down at the same time;

[0032] 3) Put 100 parts of beef obtained in step 2) into a container, put 0.3 parts of compound phosphate, 15 parts of sugar, 2 parts of salt, 3 parts of soy sauce, 1 part of cooking wine, 0.4 parts of monosodium glutamate, and 0.3 parts of pepper Stir by hand, mix evenly, and marinate for 40-60 minutes, using dry pickling method;

[0033] 4) Put the marinated beef slices in step 3) into boiling water for 30-40 minutes, skim off the foam in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com