Photoresponse self-cleaning coating and preparation method thereof

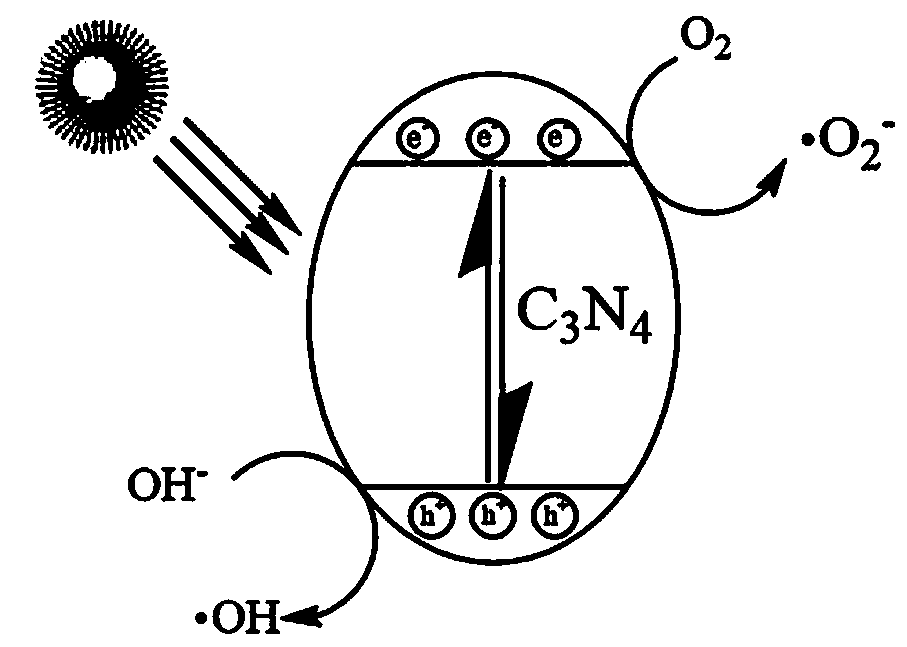

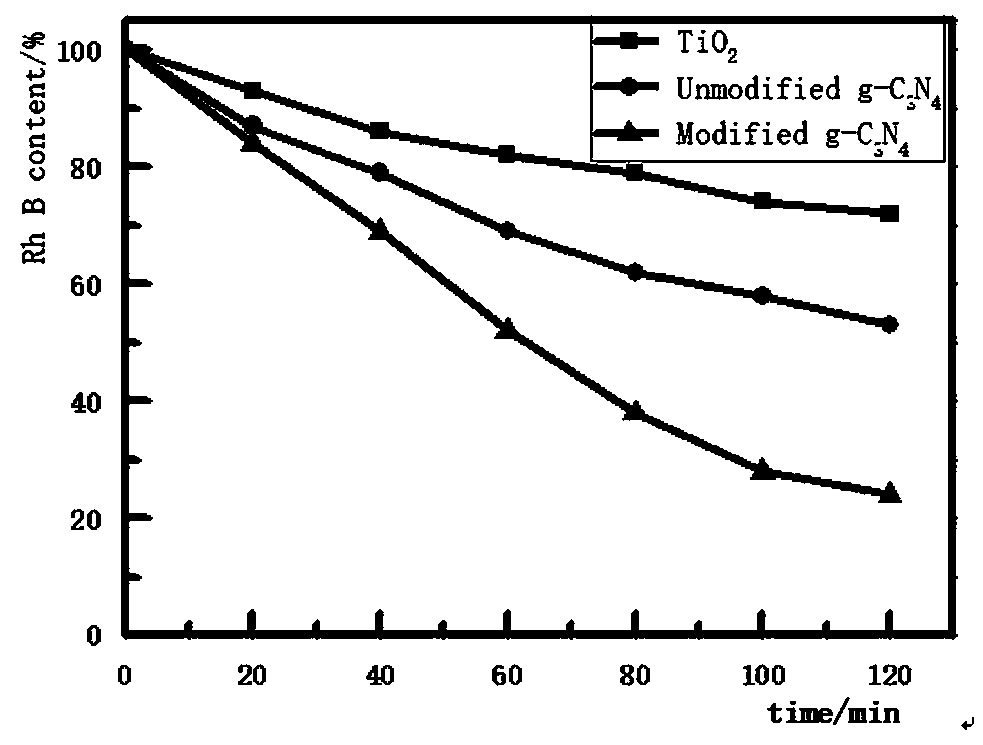

A self-cleaning, light-responsive technology, applied in the field of coatings, can solve the problem of limited light-response range and achieve the effect of improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

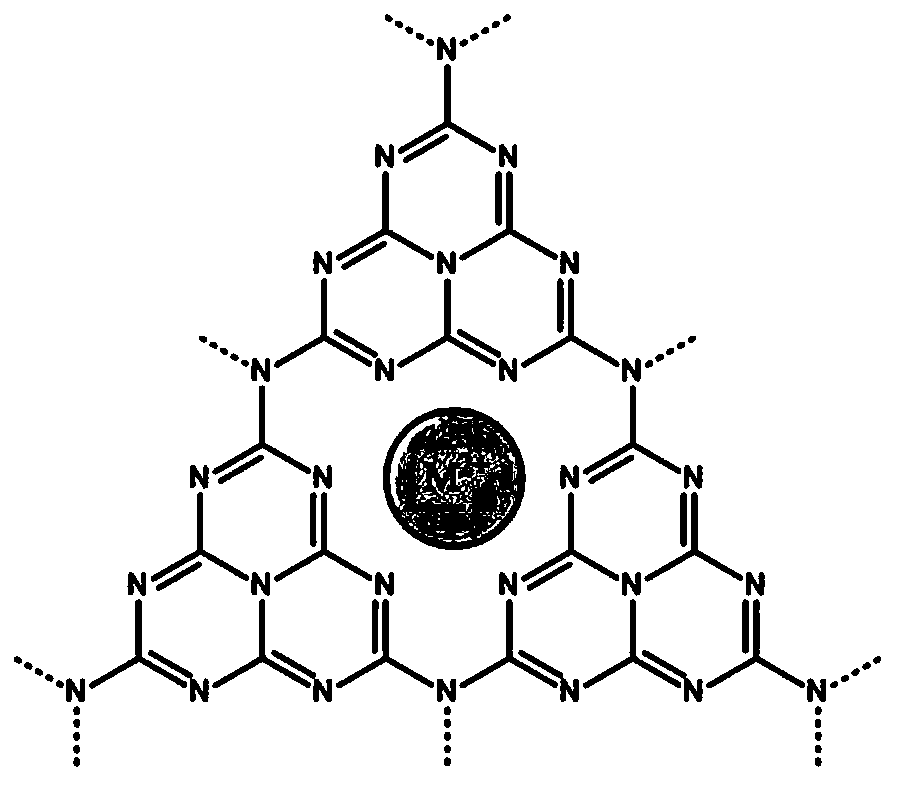

[0033] (1) Metal modified g-C 3 N 4 :

[0034] 1) Prepare 10ml (0.5wt%) CaCl 2 The solution was put into 20g melamine sample, stirred evenly and heated at 60℃ to evaporate the water;

[0035] 2) Weigh 10g of the processed sample at room temperature, add it to the crucible and put it into the muffle furnace at a temperature rise rate of 5℃·min -1 Heated to 530℃, kept at this temperature for 3h, and then naturally cooled to room temperature to obtain calcium metal doped and modified g-C 3 N 4 powder;

[0036] (2) Preparation of composite coating:

[0037] 1) Take 200 parts of water-based epoxy resin and 200 parts of water;

[0038] 2) Take 20 parts of calcium metal doped and modified g-C 3 N 4 Add to the above resin system and disperse in a ball mill for 2 hours;

[0039] 3) Take 20 parts of water-based curing agent and 50 parts of water and mix evenly; mix the mother liquor of the water-based epoxy composite paint and the diluted water-based curing agent in a ratio of 3:1 to coat the subs...

Embodiment 2

[0042] (1) Metal modified g-C 3 N 4 :

[0043] 1) Prepare 15ml (0.5wt%) CaCl 2 The solution was put into 30g melamine sample, stirred evenly and heated at 60℃ to evaporate the water;

[0044] 2) Weigh 20g of the processed sample at room temperature, add it to the crucible and put it into the muffle furnace at a temperature rise rate of 10℃·min -1 Heat to 550℃, keep it at this temperature for 4h, and then cool to room temperature naturally to obtain calcium metal doped and modified g-C 3 N 4 powder;

[0045] (2) Preparation of composite coating:

[0046] 1) Take 250 parts of water-based epoxy resin and 250 parts of water;

[0047] 2) Take 30 parts of calcium metal doped and modified g-C 3 N 4 Add to the above resin system and disperse in a ball mill for 2 hours;

[0048] 3) Take 30 parts of water-based curing agent and 80 parts of water and mix uniformly; mix the mother liquor of the water-based epoxy composite paint and the diluted water-based curing agent in a ratio of 4:1 to coat the s...

Embodiment 3

[0051] (1) Metal modified g-C 3 N 4 :

[0052] 1) Prepare 20ml (0.5wt%) CaCl 2 The solution was put into 40g melamine sample, stirred evenly and heated at 60℃ to evaporate the water;

[0053] 2) Weigh 30g of the processed sample at room temperature, add it to the crucible and put it into the muffle furnace at a temperature rise rate of 20℃·min -1 Heat to 600℃, keep it at this temperature for 6h and then cool to room temperature naturally to obtain calcium metal doped and modified g-C 3 N 4 powder;

[0054] (2) Preparation of composite coating:

[0055] 1) Take 200 parts of water-based epoxy resin and 300 parts of water;

[0056] 2) Take 40 parts of calcium metal doped and modified g-C 3 N 4 Add to the above resin system and disperse in a ball mill for 2 hours;

[0057] 3) Take 40 parts of water-based curing agent and 100 parts of water and mix evenly; mix the mother liquor of the water-based epoxy composite paint and the diluted water-based curing agent in a ratio of 5:1 to coat the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com