Manufacturing method for composite steel pipe through laser manufacturing

A technology of composite steel pipe and manufacturing method, applied in the direction of manufacturing tools, grinding/polishing equipment, coating, etc., to achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

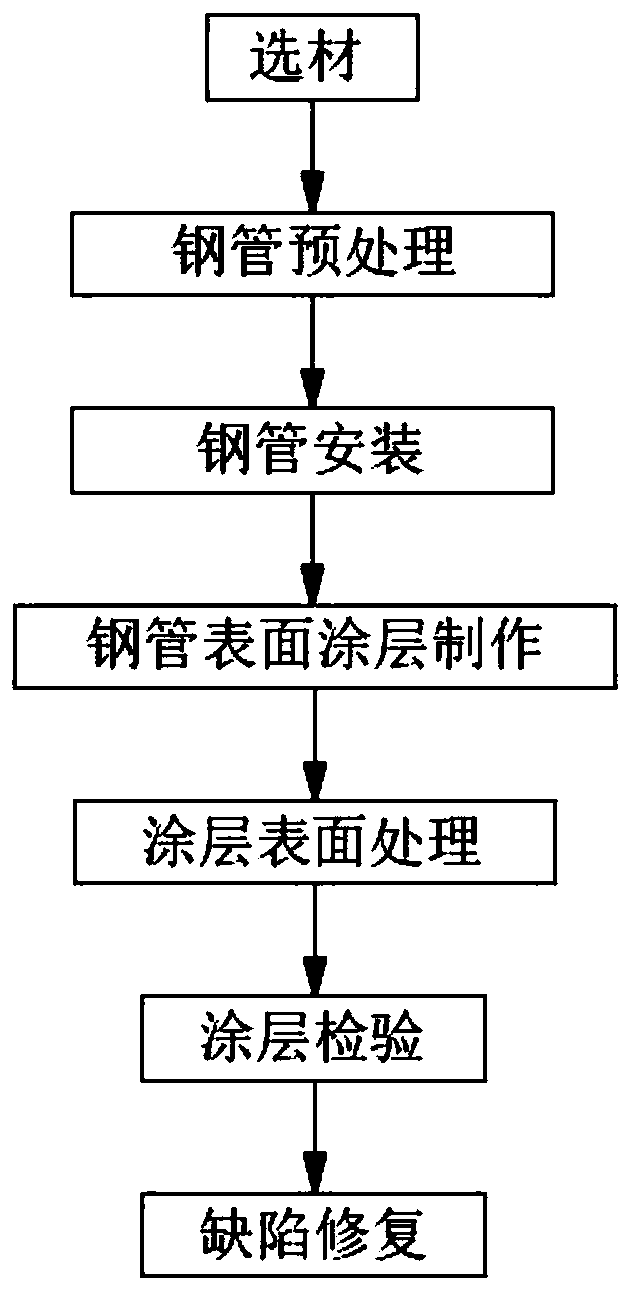

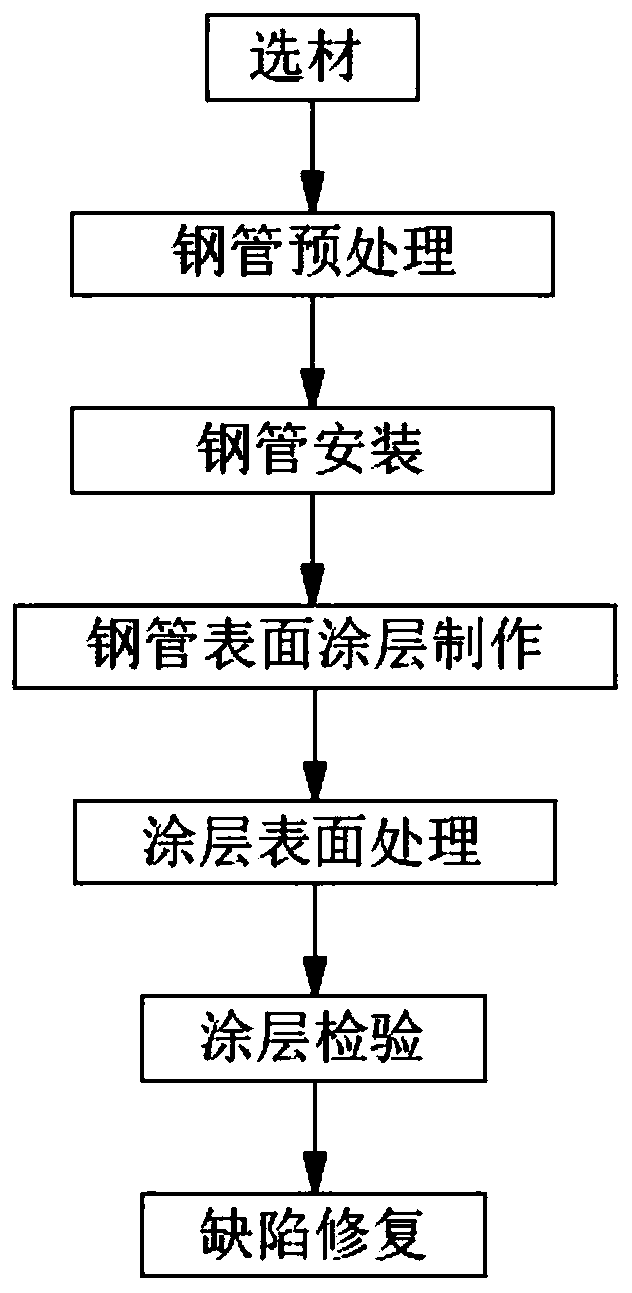

Method used

Image

Examples

Embodiment 1

[0025] A method for manufacturing "20G+316L" composite steel pipe by laser, the main function of the steel pipe is to improve the corrosion resistance of the steel pipe, comprising the following steps:

[0026] S1, material selection, select 20G steel pipe as the base material;

[0027] S2, 20G steel pipe pretreatment, the rust on the surface of the steel pipe is cleaned by shot blasting;

[0028] S3, 20G steel pipe installation, install the pretreated steel pipe on the rotary tooling of the complete laser cladding equipment; wipe the surface to be clad with alcohol to remove residual oil;

[0029] S4, 20G steel pipe surface coating production, first add 316L consumable powder into the powder feeder of the laser cladding complete set of equipment, and then use laser cladding process to clad 316L powder on the surface of 20G steel pipe;

[0030] S5. Coating surface treatment. After the 316L coating is produced, the surface of the steel pipe is properly polished to remove the p...

Embodiment 2

[0038] A method for manufacturing "20G+431" composite steel pipe by laser, the main function of the steel pipe is to improve the corrosion resistance and wear resistance of the steel pipe, comprising the following steps:

[0039] S1, material selection, select 20G steel pipe as the base material;

[0040] S2, 20G steel pipe pretreatment, the rust on the surface of the steel pipe is cleaned by shot blasting;

[0041] S3, 20G steel pipe installation, install the pretreated steel pipe on the rotary tooling of the laser cladding machine complete set of equipment; wipe the surface to be clad with alcohol to remove residual oil;

[0042] S4, 20G steel pipe surface coating production, first add 431 consumable powder into the powder feeder of the laser cladding machine complete set of equipment, and then use laser cladding process to clad 431 powder on the surface of 20G steel pipe;

[0043] S5. Coating surface treatment. After the 431 coating is produced, the surface of the steel pi...

Embodiment 3

[0051] A manufacturing method of laser manufacturing "20G+NiCrMo alloy" composite steel pipe, the main function of the steel pipe is to improve the high temperature corrosion resistance of the steel pipe, comprising the following steps:

[0052] S1, material selection, select 20G steel pipe as the base material;

[0053] S2, 20G steel pipe pretreatment, the rust on the surface of the steel pipe is cleaned by shot blasting;

[0054] S3, 20G steel pipe installation, install the pretreated steel pipe on the rotary tooling of the complete laser cladding equipment; wipe the surface to be clad with alcohol to remove residual oil;

[0055] S4, 20G steel pipe surface coating production, first add NiCrMo alloy consumable powder into the powder feeder of the laser cladding complete set of equipment, and then use the laser cladding process to clad the NiCrMo alloy powder on the surface of the 20G steel pipe;

[0056] S5. Coating surface treatment. After the NiCrMo alloy coating is produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com