Prevention and treatment method for goaf water under condition of repeated mining of thick seam upper slices destructed by minitype coal mines

A technology of old empty water and thick coal seam, which is applied in the field of old empty water prevention and control under the condition of re-mining of layers on thick coal seams and damaged by small kilns, can solve the uncertainty of the accuracy of old empty water detection and the inability to ensure old Empty and water drainage is clean and thorough, and the exploration trajectory is uncontrollable, etc., to shorten the drainage time, eliminate the old empty water problem, and improve the drilling hole formation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

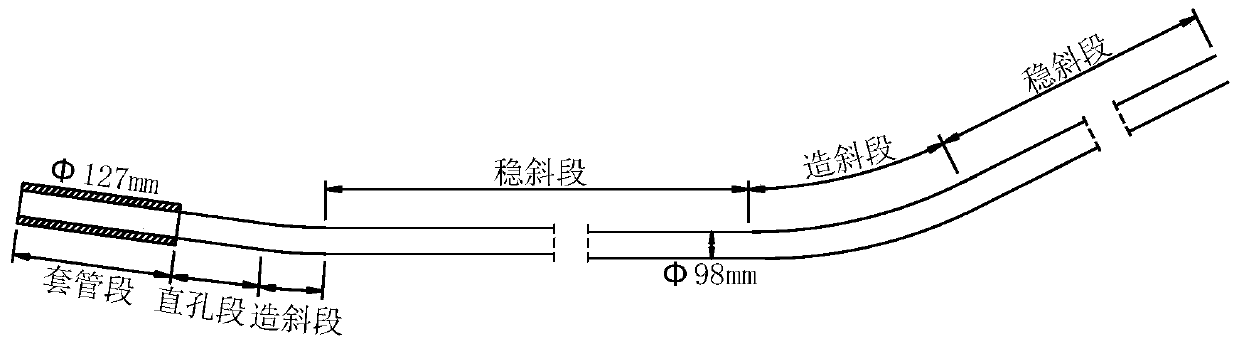

Method used

Image

Examples

Embodiment Construction

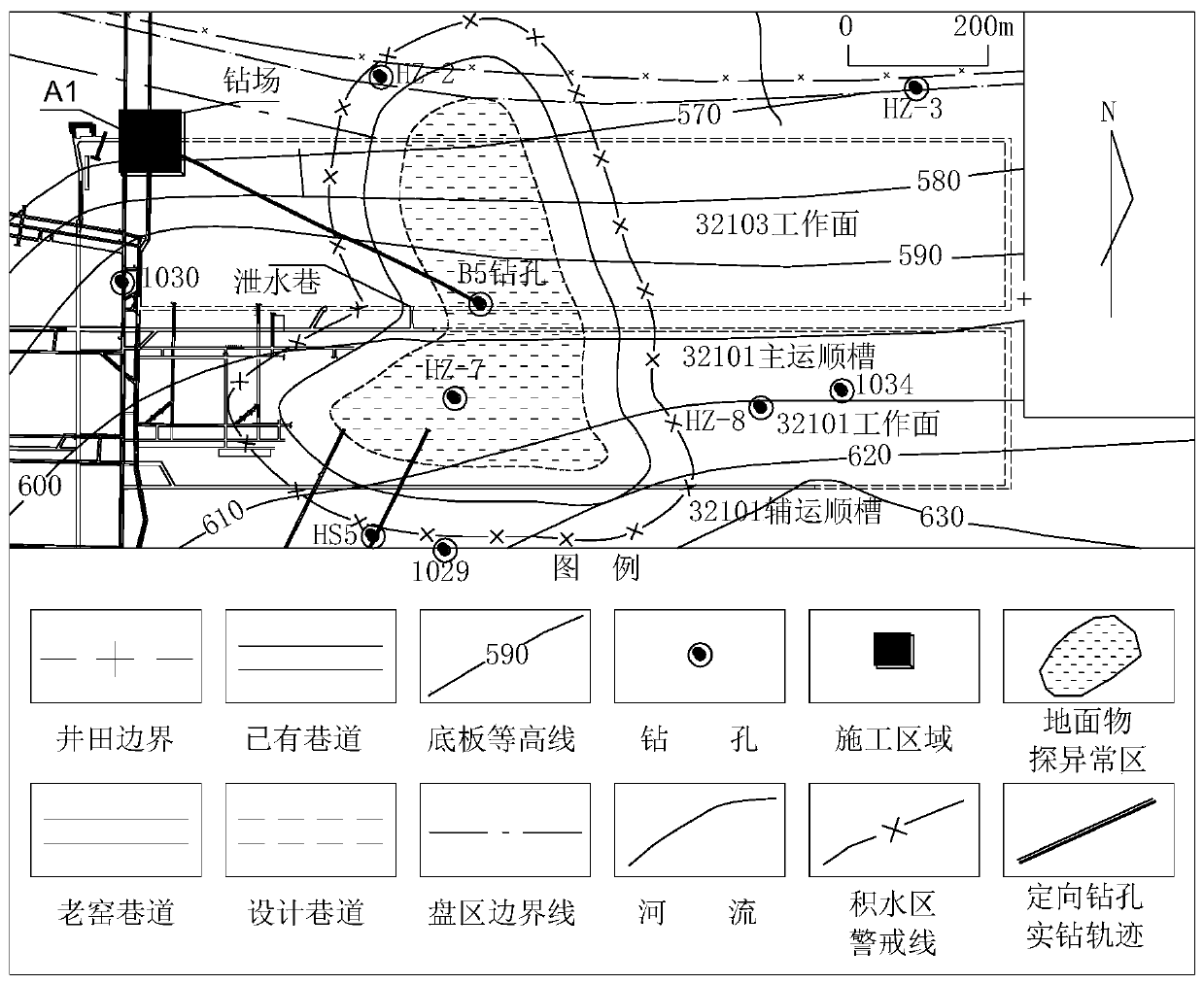

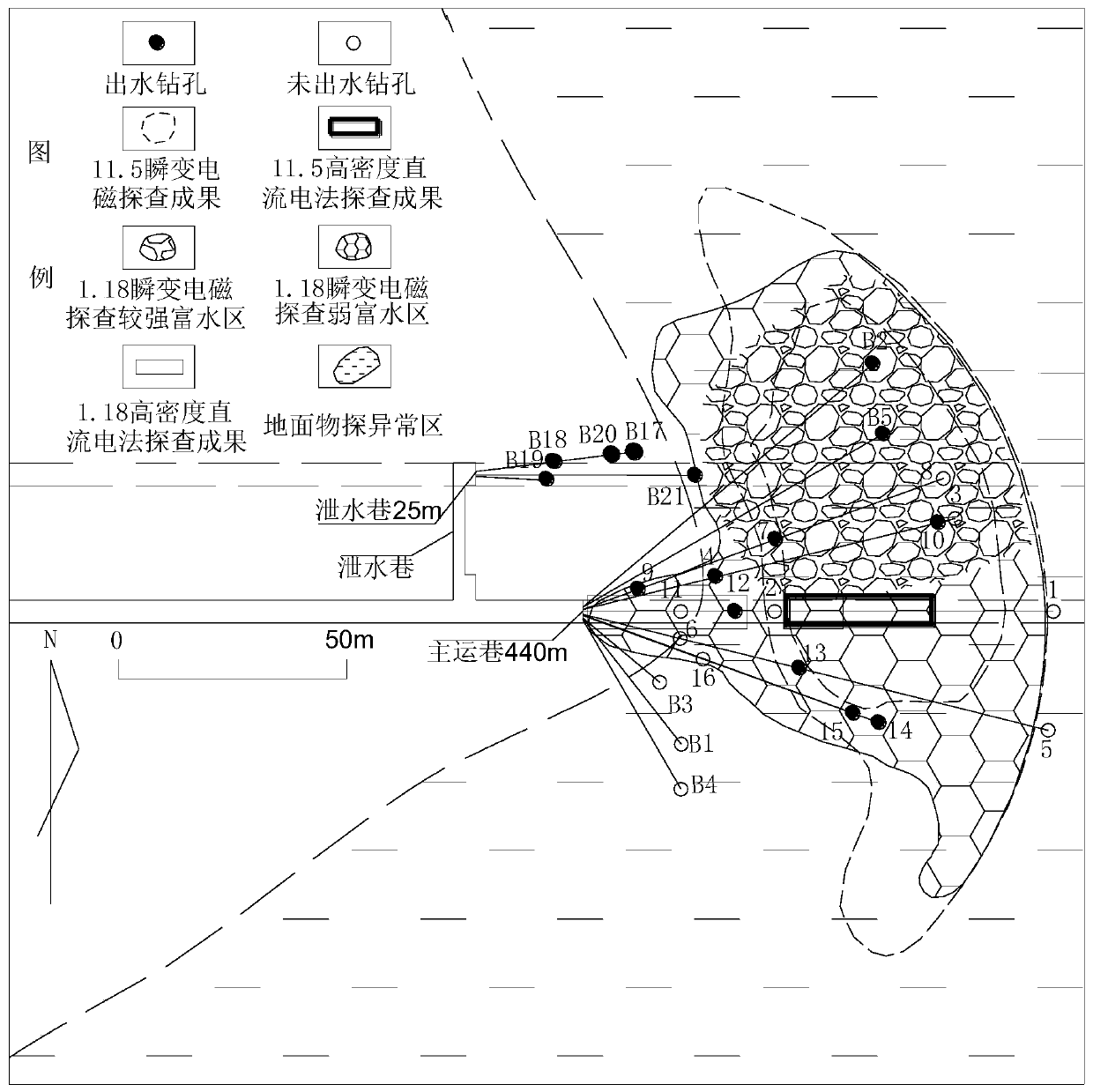

[0033] The content of the present invention will be further described below in conjunction with China Coal Huajin Group Hanzui Coal Industry Co., Ltd. as an example.

[0034] China Coal Huajin Group Hanzui Coal Industry Co., Ltd. is formed by the integration of 4 small coal mines and surrounding resources that are not suitable for mining. The main mine is 2 # The strata on the coal seam were damaged to varying degrees. Due to the non-standard mining methods and techniques in small coal mines, and the poor control of the excavation engineering position, the situation of water accumulation was complicated, and the mine mining was deeply affected by the old empty flood. Among them, the delamination damage on the 32101 working face is serious, and the mining of the working face is deeply restricted by the old empty water damage. 440m, took a total of 1.5 years, which seriously restricted the safe and efficient production of the mine. In order to solve the problem that the old empt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com