Material surface anti-cavitation performance test method based on laser driving

A laser-driven, anti-cavitation technology, used in the analysis of materials, strength characteristics, testing wear resistance, etc., can solve the incompatibility of the service conditions of the steam turbine unit, it is impossible to simulate the cavitation effect and activation effect of the last stage blade of the steam turbine, It is impossible to comprehensively evaluate the anti-cavitation performance of blade materials, so as to achieve the effect of realistic simulation environment and strong data reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

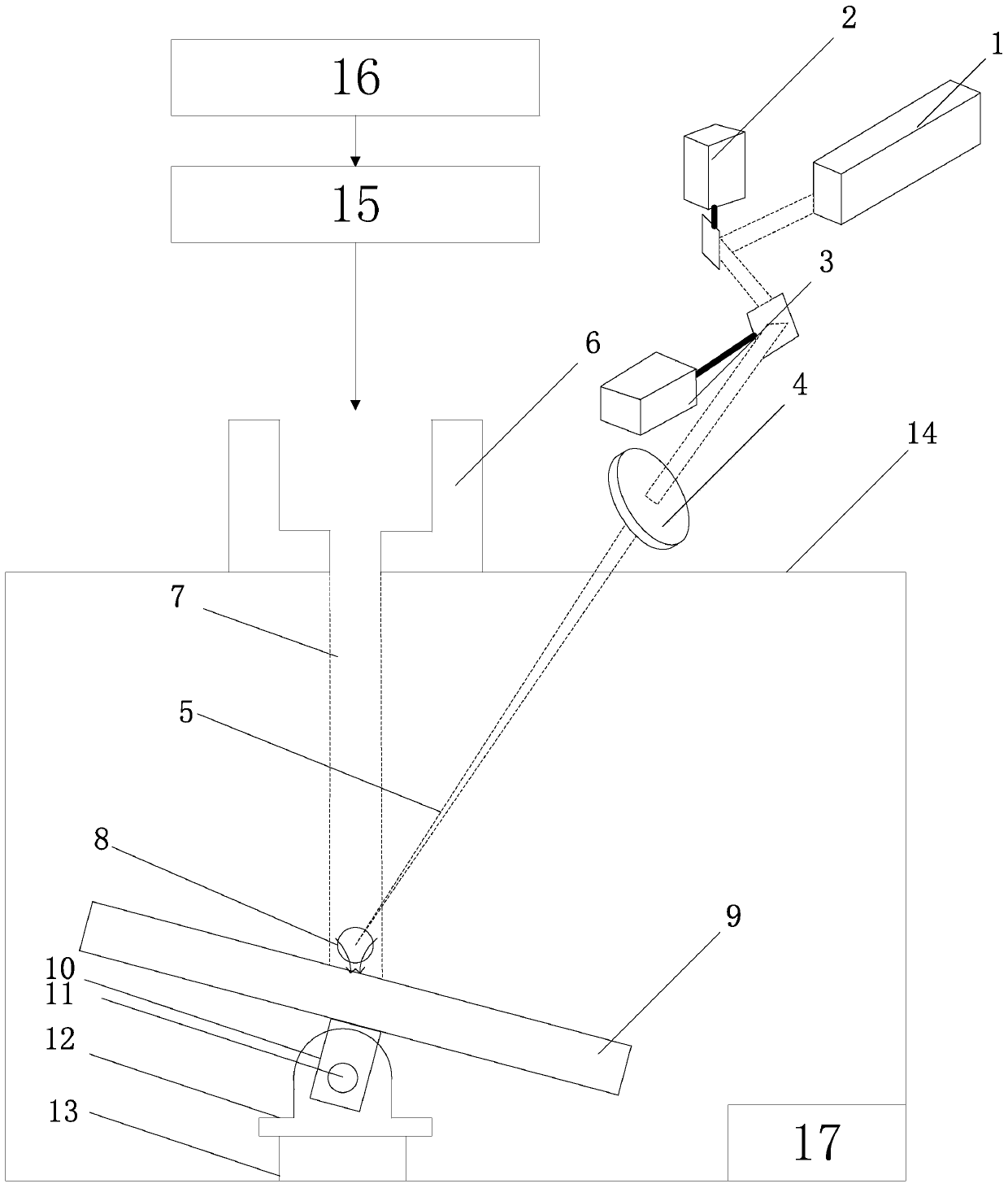

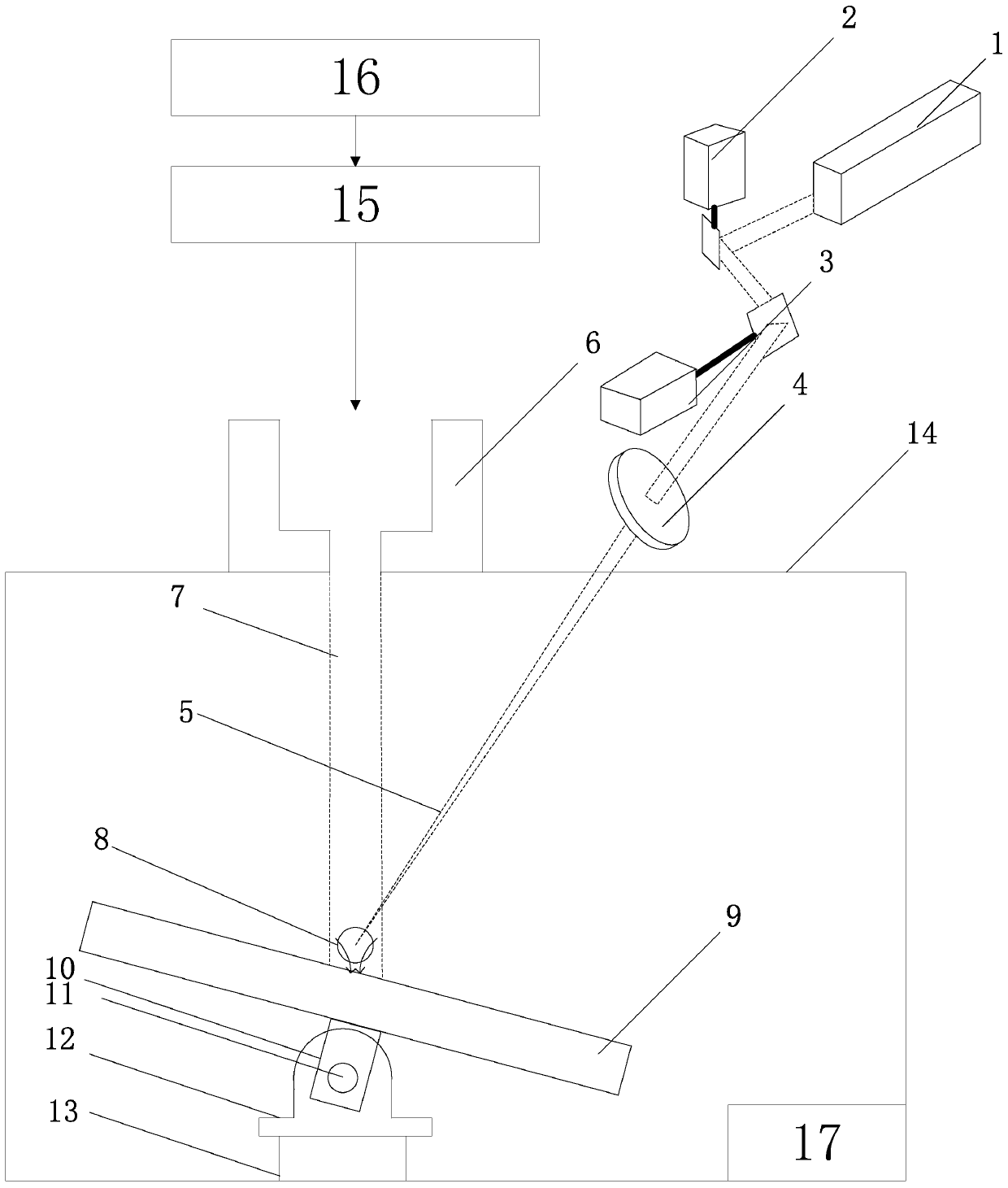

[0021] Further illustrate the present invention below in conjunction with accompanying drawing.

[0022] A method for testing the anti-cavitation performance of a material surface driven by a laser, comprising the steps of:

[0023] (1) When the test starts, the sample 9 to be tested is fixed on the clamp 10, and the spatial position and the angle of inclination of the clamp 10 are adjusted to change the spatial position and the angle of inclination of the sample to be tested 9.

[0024] (2) Add specified water body to the water tank 16, and use the magnetic stirrer at the bottom of the water tank 16 to stir the water body. After the water body is stirred until uniform, the water jet 7 is generated by the high-pressure water generator 15 and ejected to the test sample 9 surface to generate water hammer and shock waves.

[0025] The water body can be distilled water, deionized water, tap water, distilled water with microparticles, deionized water with microparticles, tap water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com