Gallium nitride power module packaging method and pressurizing device

A technology for power modules and packaging methods, which is applied to semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of poor packaging quality and low yield of gallium nitride power modules, and achieve high appearance quality and high reliability. The effect of balanced force and uniform amount of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

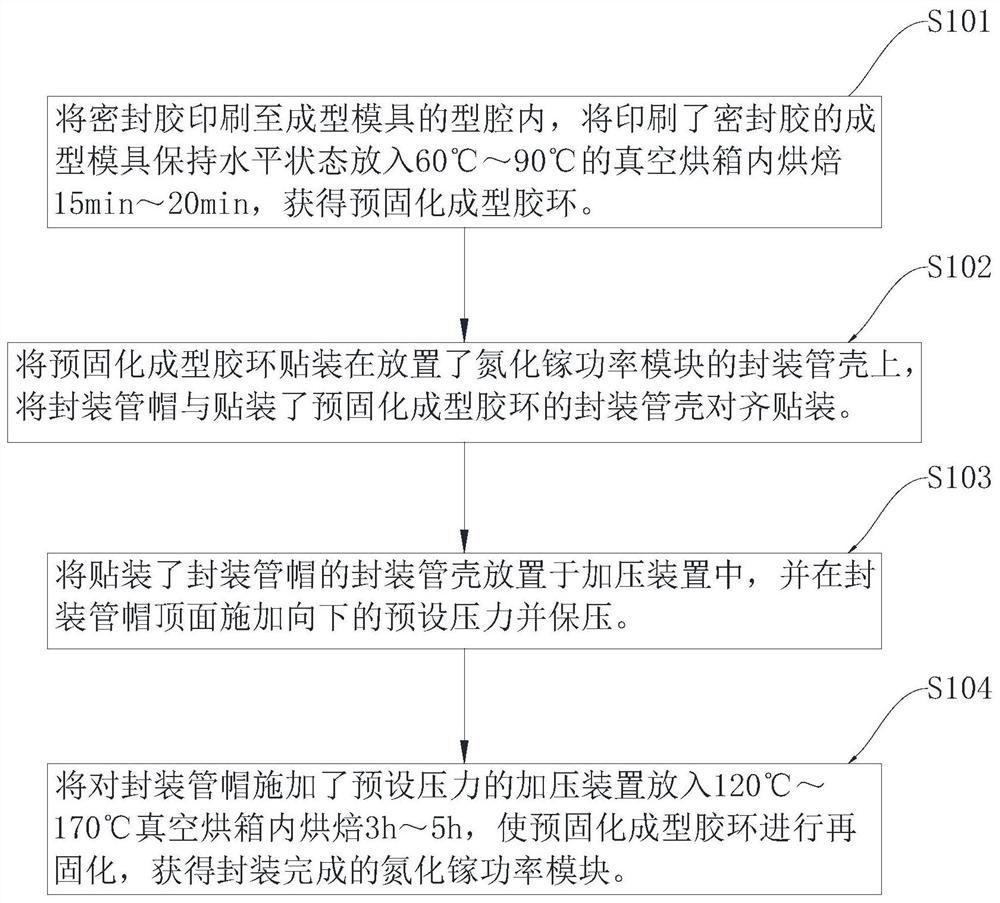

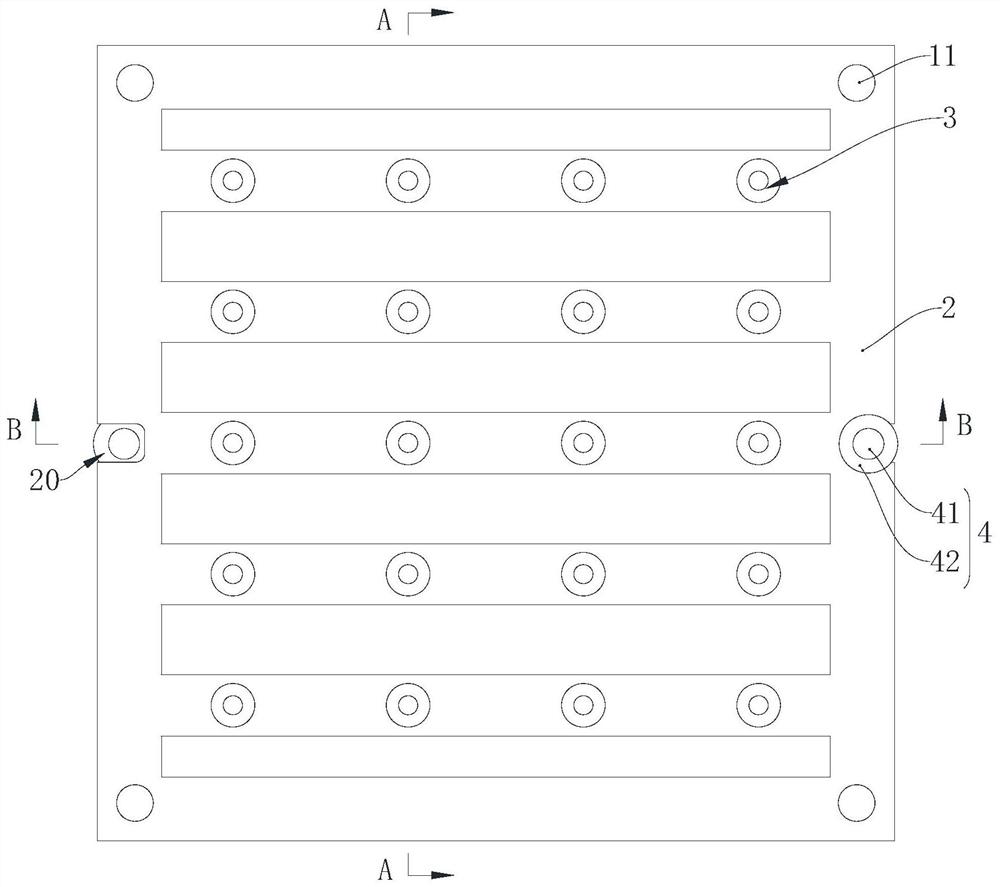

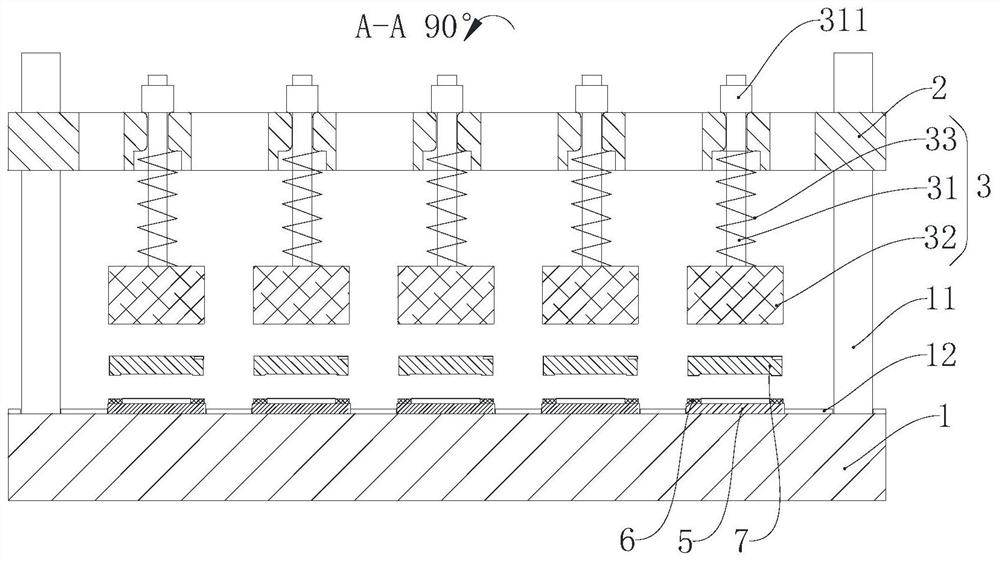

[0042] Please also refer to Figure 1 to Figure 4 , Image 6 and Figure 7 , the gallium nitride power module packaging method provided by the present invention will now be described. The gallium nitride power module packaging method includes the following steps:

[0043] Step S101, printing the sealant into the cavity 80 of the molding mold 8, keeping the mold 8 printed with the sealant in a horizontal state and putting it into a vacuum oven at 60°C to 90°C for 15min to 20min to obtain a pre-cured molding glue Ring 6;

[0044] Step S102, attaching the pre-cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com