Marine sewage treatment system and method

A sewage treatment system and marine technology, applied in the field of treatment systems, can solve the problems of many installation space restrictions, complex operation, large volume, etc., and achieve the effect of improving the utilization rate of alkaline water, simple operation, and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

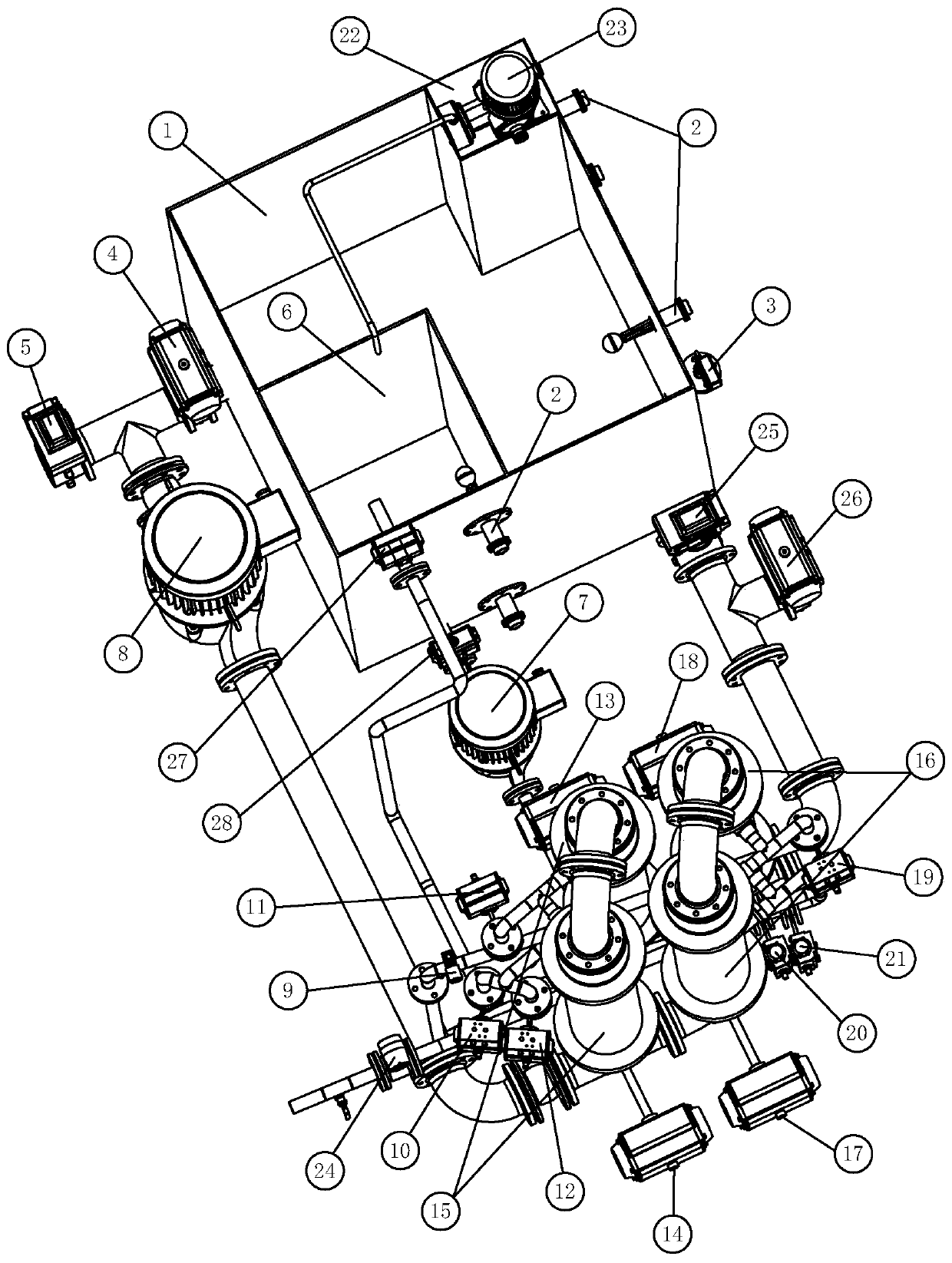

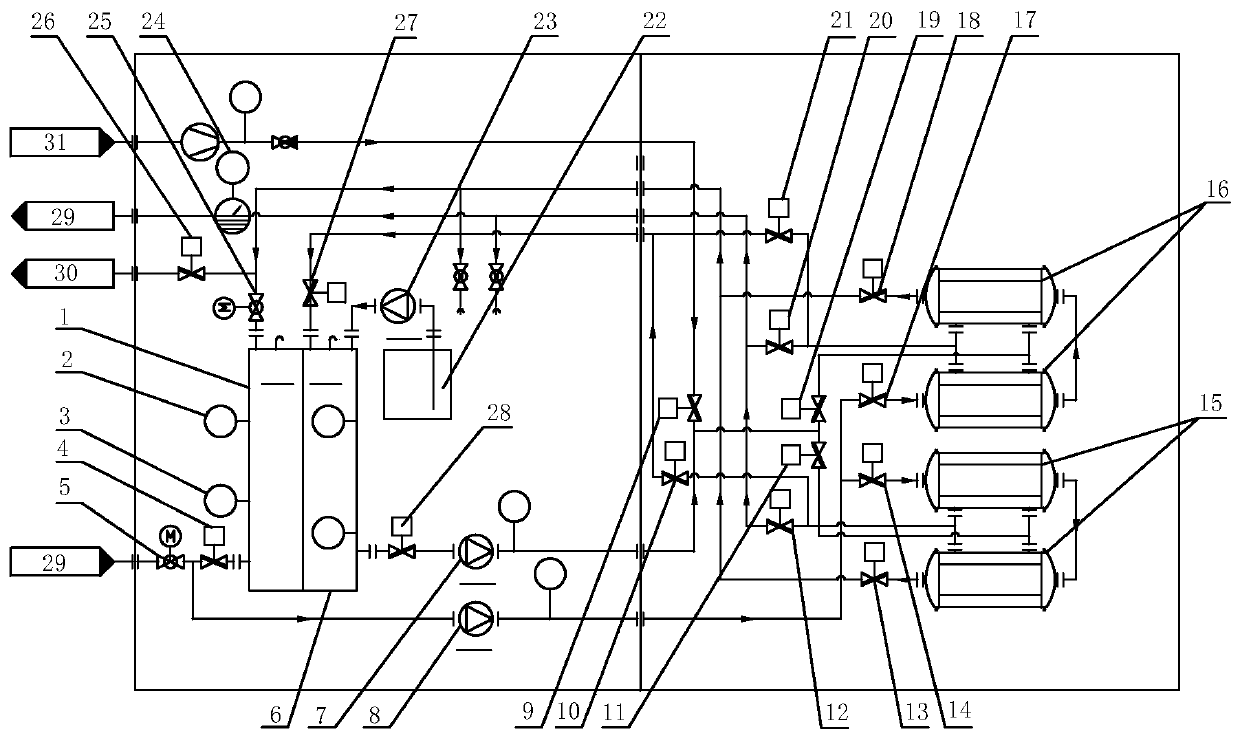

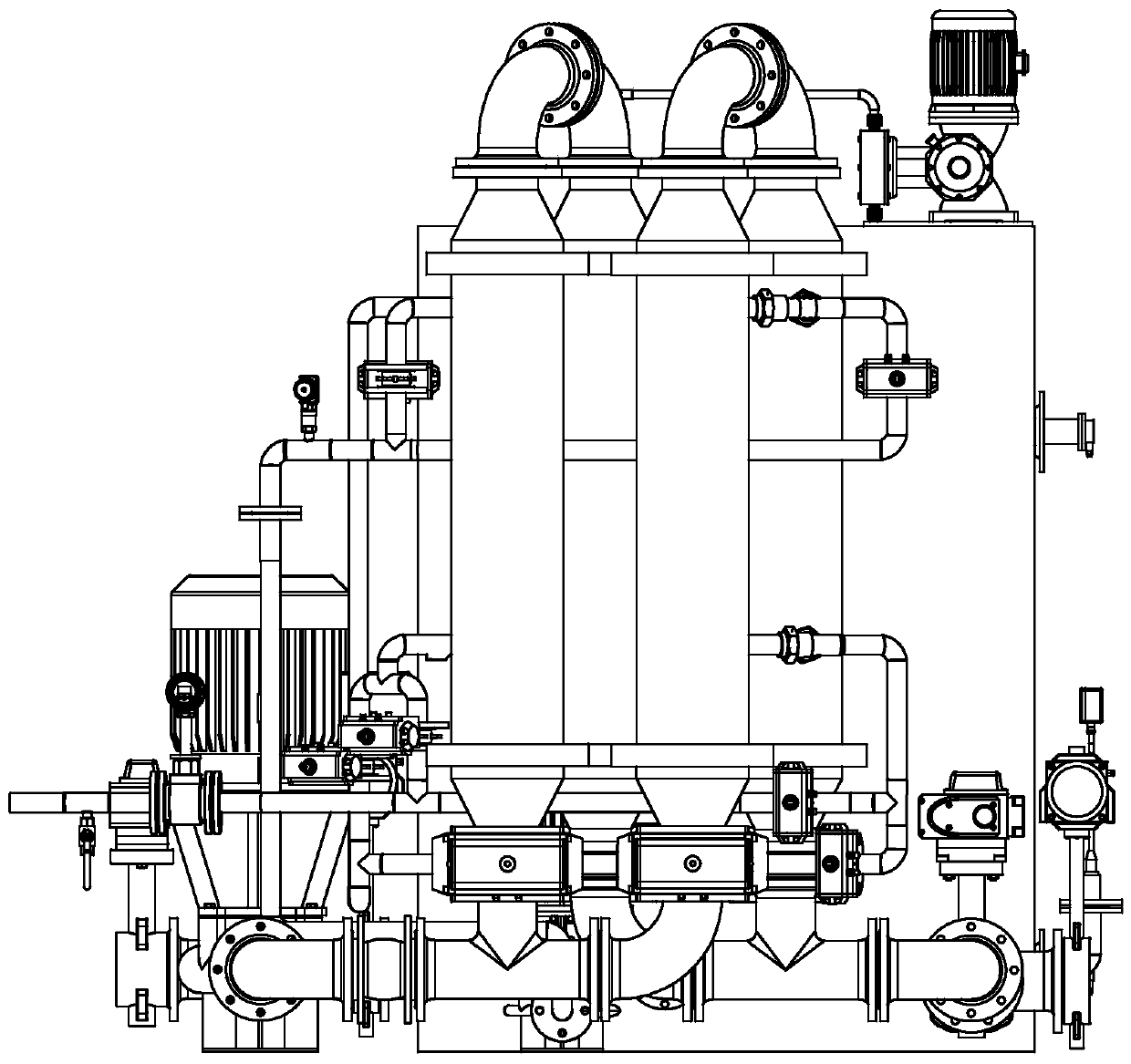

[0035] Such as Figure 1-6A kind of marine sewage treatment system shown, comprises circulating tank 1, first filter group 15, the second filter group 16, and circulating tank 1 communicates with the inlet of first filter group 15, the second filter group 16 respectively through circulating pump 8 Connection; both the first filter group 15 and the second filter group 16 are membrane filters. Membrane filters include silicon carbide membrane filters and alumina filters; the filter membrane of silicon carbide membrane filters adopts silicon carbide ceramic membranes, which have the characteristics of large flux and can be regenerated repeatedly; by filtering silicon carbide membranes, Reduce suspended solids, grease and COD in water samples to meet the requirements of subsequent treatment processes; it has the following advantages: hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com