Method for improving rare earth grade of mixed rare earth ore

A mixed rare earth and rare earth technology, applied in the direction of solid separation, etc., can solve the problems that cannot be completely improved, and achieve the effects of convenient industrial organization production, high recovery rate of rare earth, and simple and effective process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] 1. The nature of raw ore

[0033] The ore samples used in the test of this project were jointly collected by Baotou Iron and Steel Mining Research Institute and Baoshan Mining Company. The specific mining method is to determine the sampling date from June 12, 2017 to June 17, 2017 under all normal production conditions of Baoshan Mining. The sampling point is the strong magnetic tailings sampling point of the iron processing workshop. The sampling method is once a day in the morning and once in the afternoon, ten times in total, and dried in the shade in Baoshan Mining Institute. After the two sides are mixed together, it is about 1400 kg. This ore sample was confirmed to be representative by both parties, and it was taken back to Baotou Iron and Steel Mining Research Institute as a test ore sample.

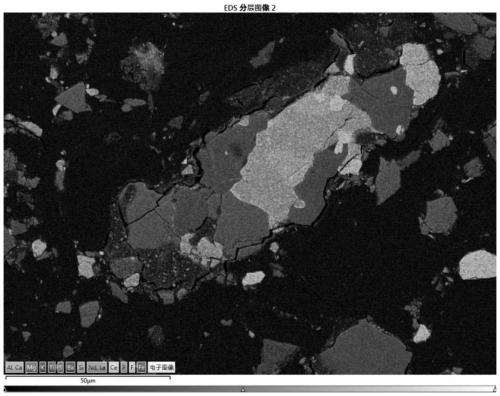

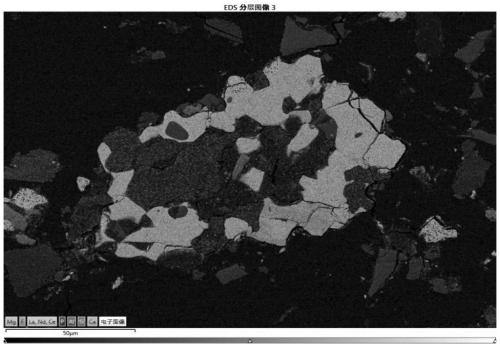

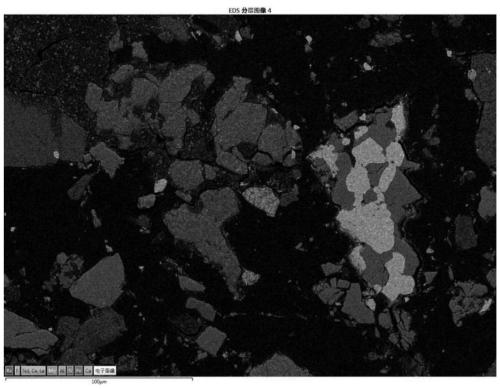

[0034] See the attachment for the scanning electron microscope picture of the mineral surface of the raw ore Figure 1 ~ Figure 3 .

[0035] 1.1 Raw ore analysis

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com