Lithium hydroxide powder packaging system

A packaging system and lithium hydroxide technology, which is applied in the field of material packaging equipment, can solve the problems of lithium hydroxide having a spicy taste, the environment and the hazards of operators, etc., to improve accuracy, ensure weighing accuracy, and prevent materials from arching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

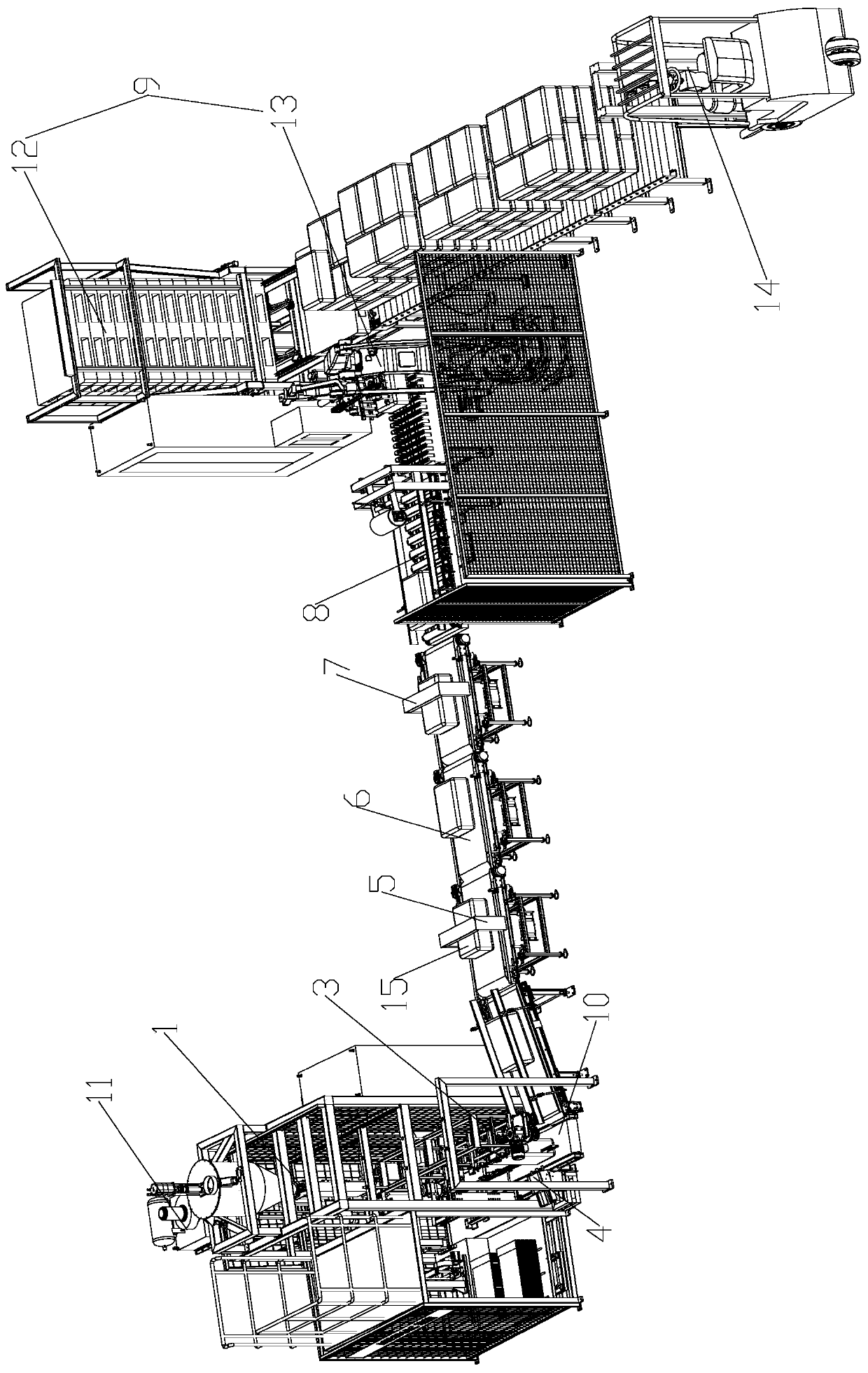

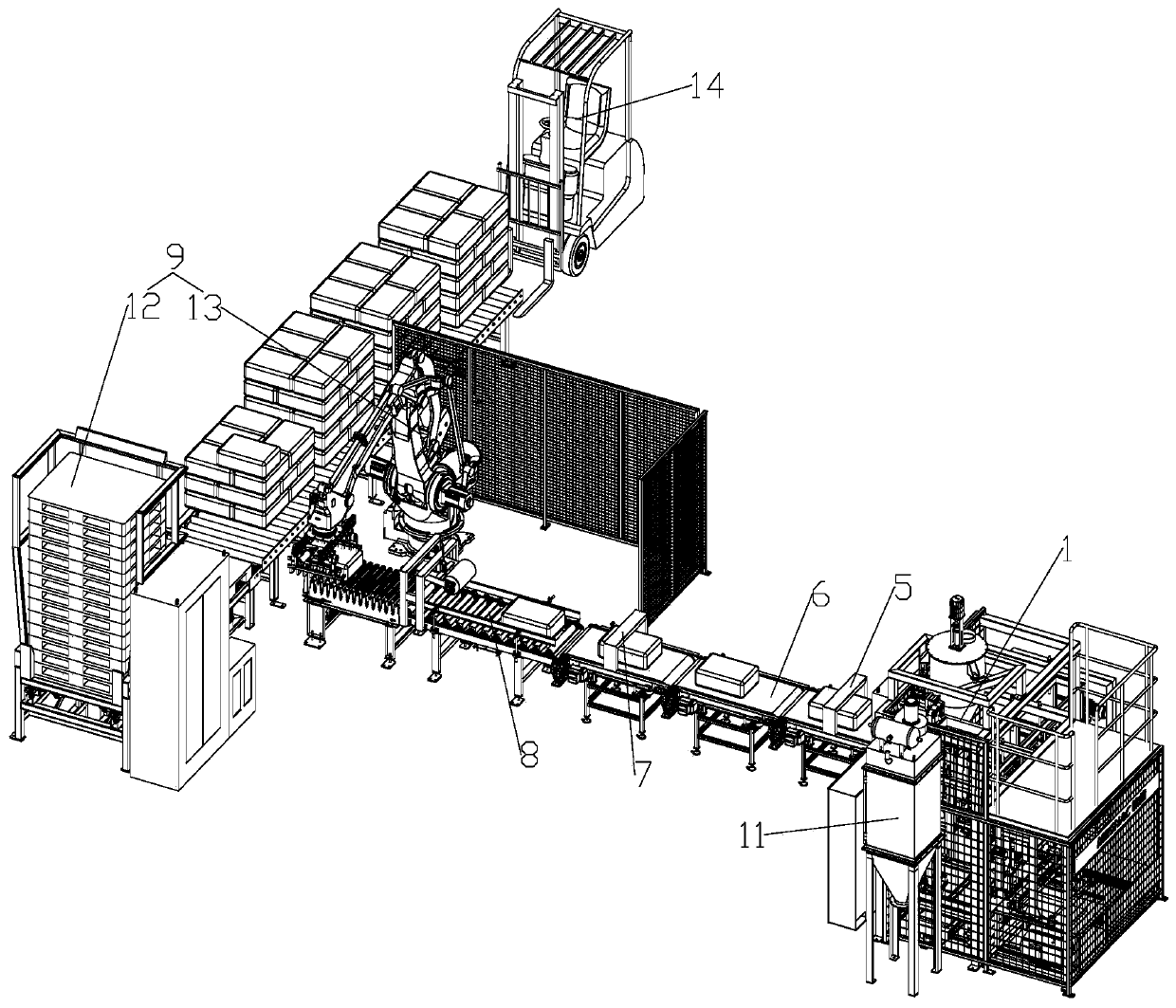

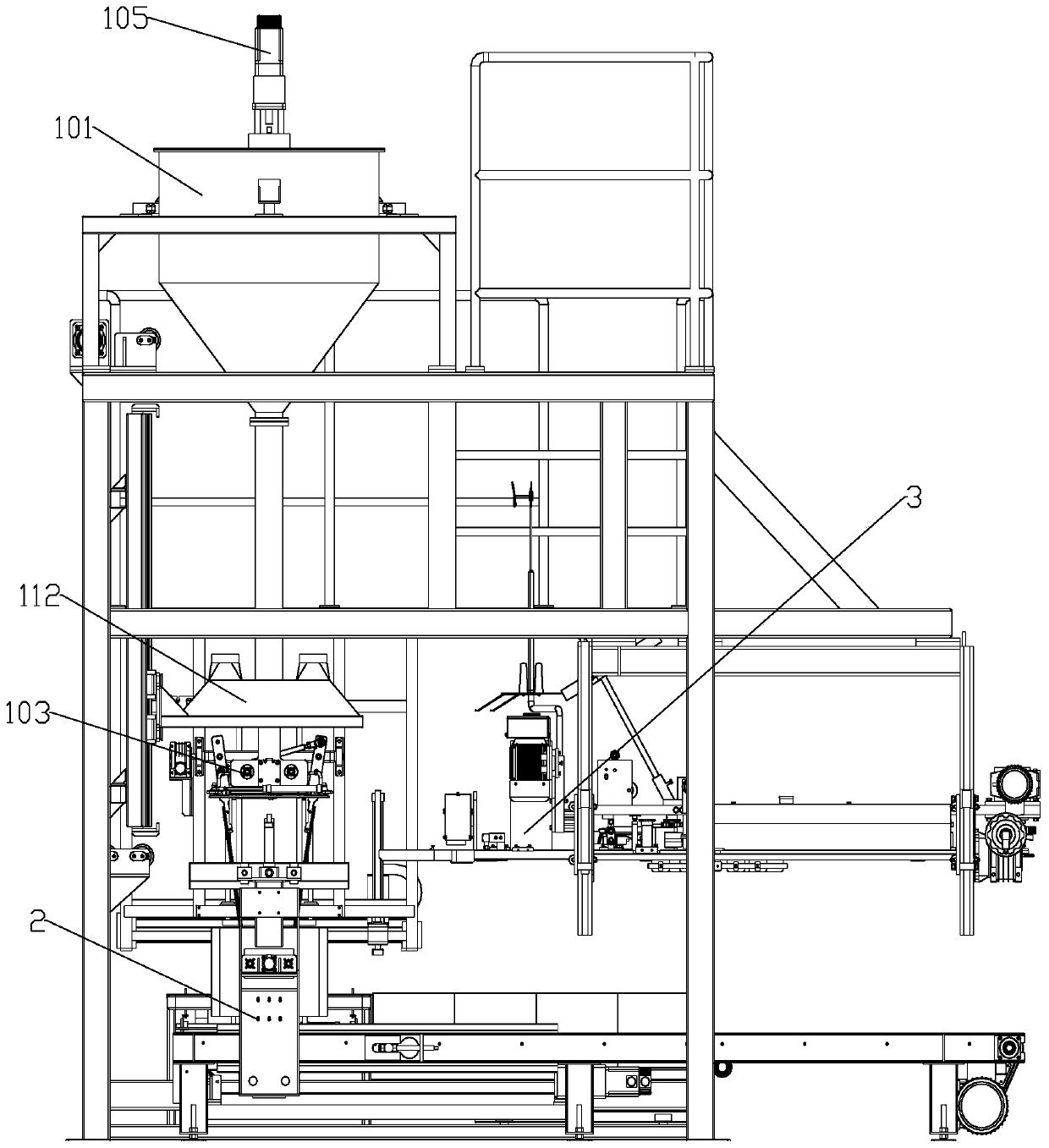

[0029]A lithium hydroxide powder packaging system, comprising a packaging machine 1, a bag holding walking mechanism 2, a bag sewing machine 3, a bag pushing machine 4, a metal detector 5, a weight rechecking machine 6, Shaping machine 7, inkjet conveyor 8, palletizing mechanism 9 and control system (not shown in the figure), described packaging machine comprises frame 100, feed bin 101, single-point load cell 102, bag clamping mechanism 103, A bag supporting mechanism 104, the feed bin 101 is fixed on the frame 100, one end of the single point load cell 102 is fixed on the frame 100, and the other end is fixedly connected to the bag clamping mechanism 103, so The bag clamping mechanism 103 is fixedly connected to the bag stretching mechanism 104; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com