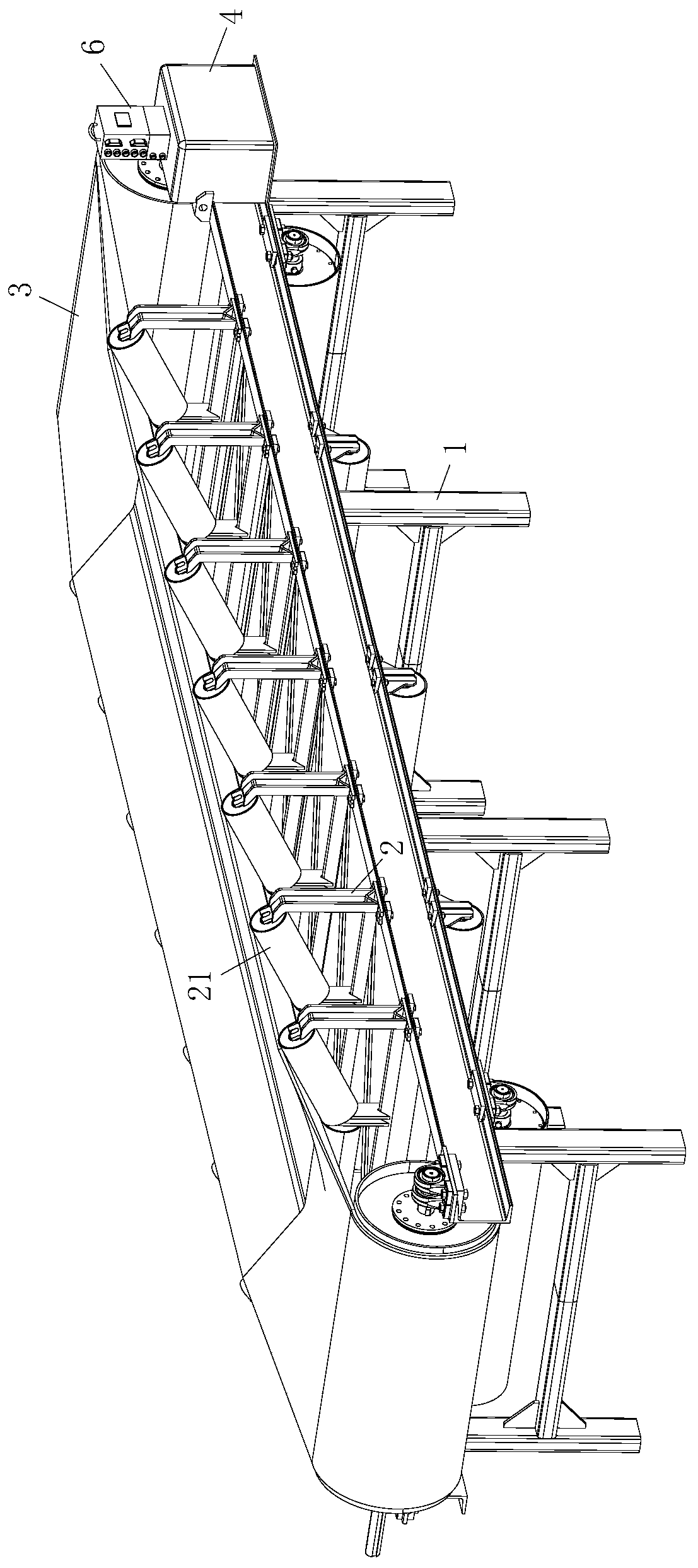

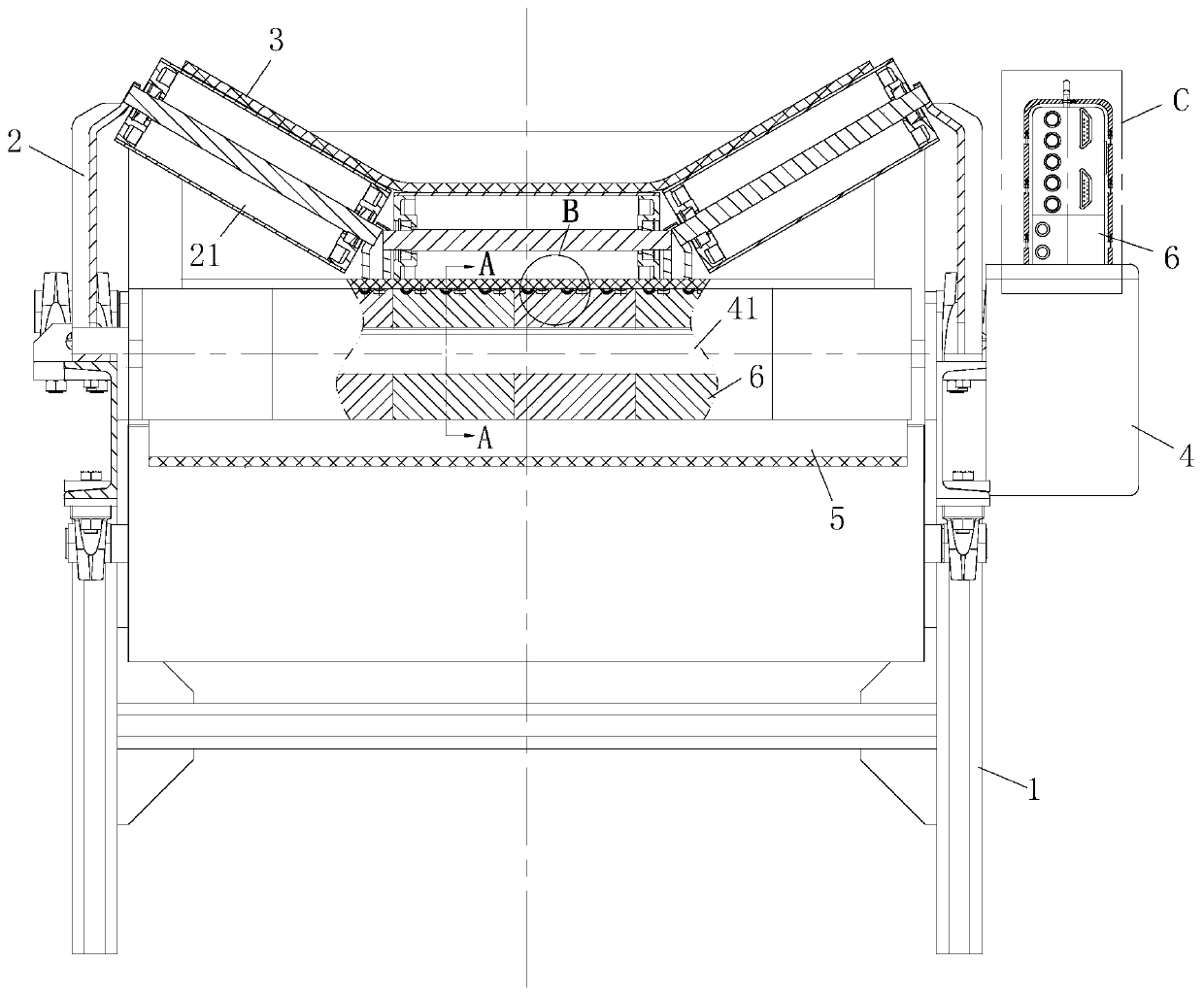

Mining belt conveyor control and protection system

A belt conveyor, control and protection technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of life and health hazards of workers, affecting the smooth progress of production, increasing the tension of the conveyor belt, etc. Improve work quality and service life, improve stability and effectiveness, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

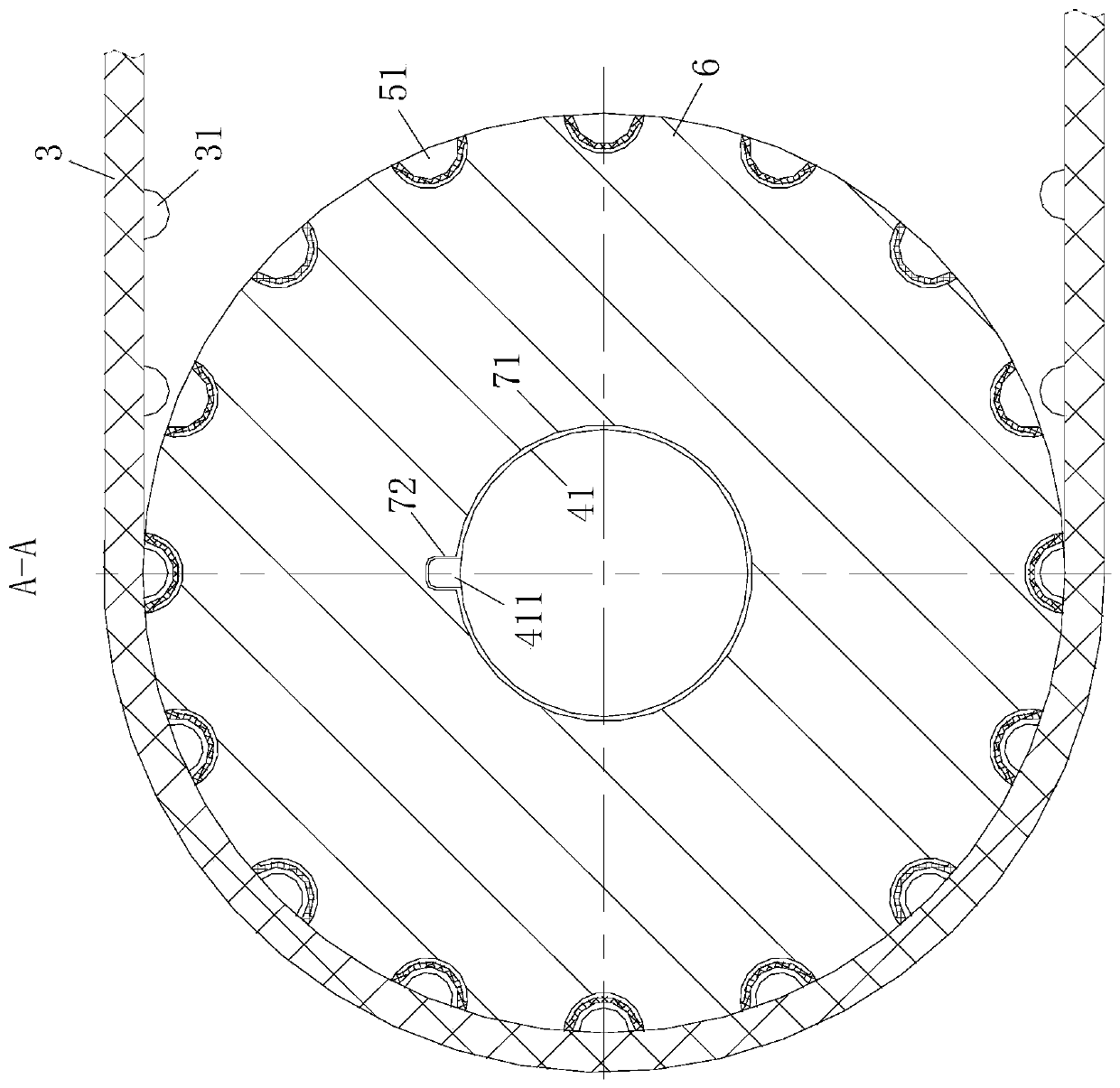

[0026] As an embodiment of the present invention, the inside of the groove 51 is fixed with an elastic pad 52 conforming to the shape of its inner wall, the elastic pad 52 is made of elastic rubber material, and the elastic pad 52 is far away from The outer surface of the inner wall of the groove 51 is set as a rough surface; during work, the inner wall of the groove 51 is provided with an elastic pad 52 that fits the shape of the inner wall, and when the conveyor belt 3 slides and drives the protrusion 31 to the side of the groove 51 When the wall is squeezed, the elastic pad 52 between the two can effectively buffer the impact force of the protrusion 31, and the compressed elastic pad 52 can not only rebound the protrusion 31 and restore it to its original position. In the normal state, it can also reduce the wear caused by excessive contact friction between the protrusion 31 and the groove 51, and can also reduce the damage caused by the direct contact and extrusion of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com