Full-automatic frame inserting machine for glass cover plate

A glass cover, fully automatic technology, used in conveyor objects, object stacking, object unstacking and other directions, can solve the problems of wasting workers, workers are easy to fatigue, scratches, etc., to save the overall occupied space, Ingenious and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

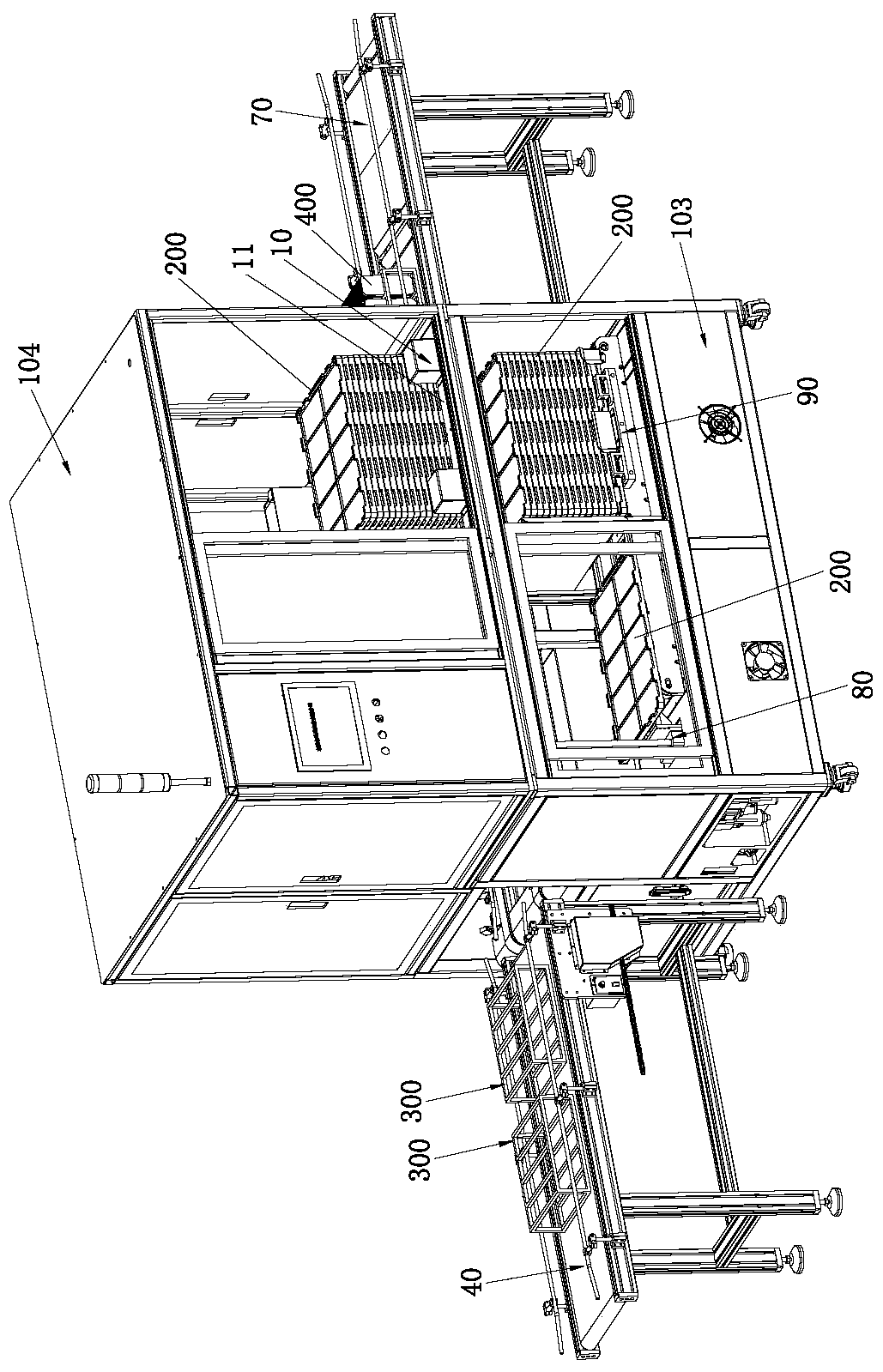

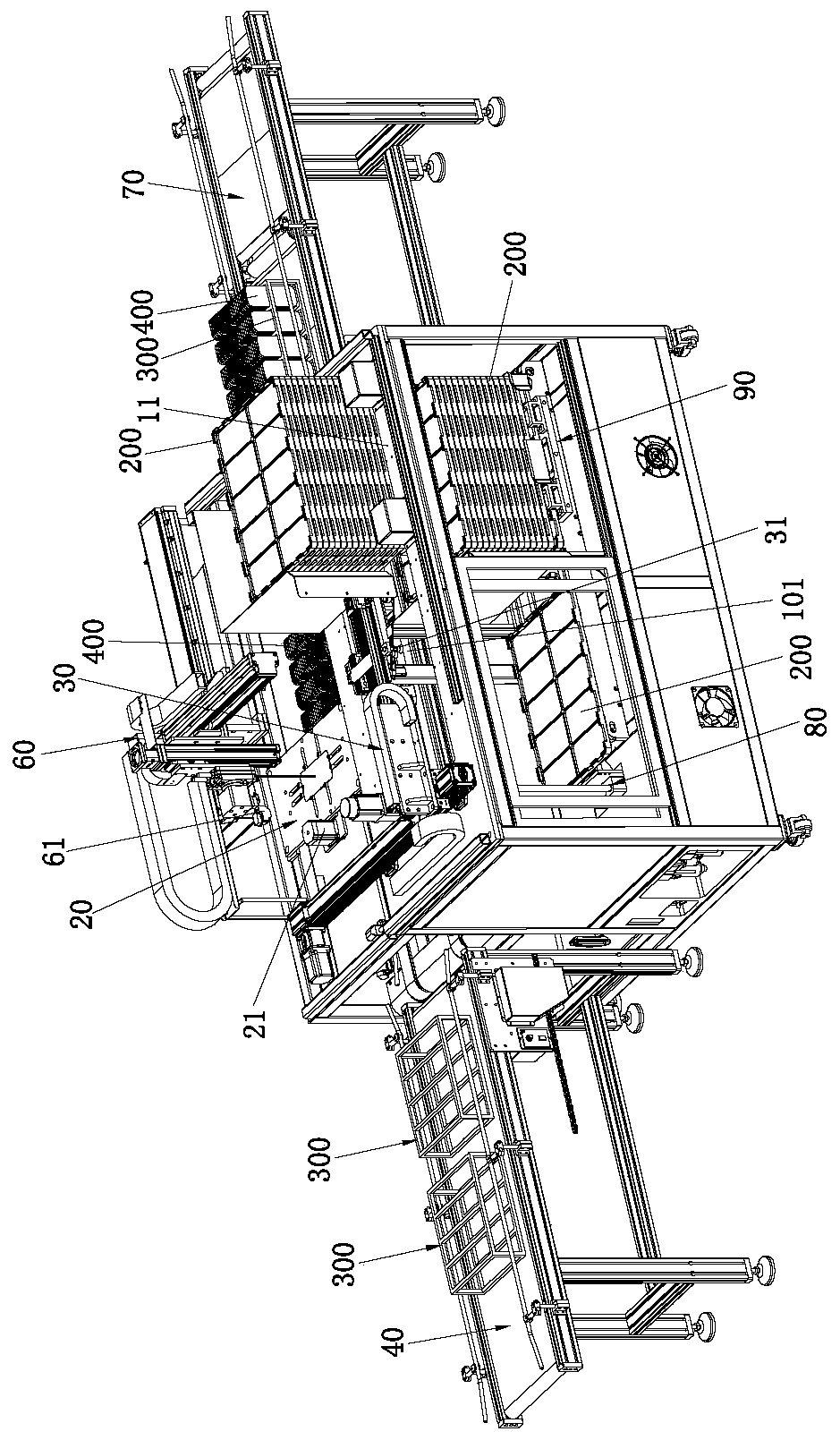

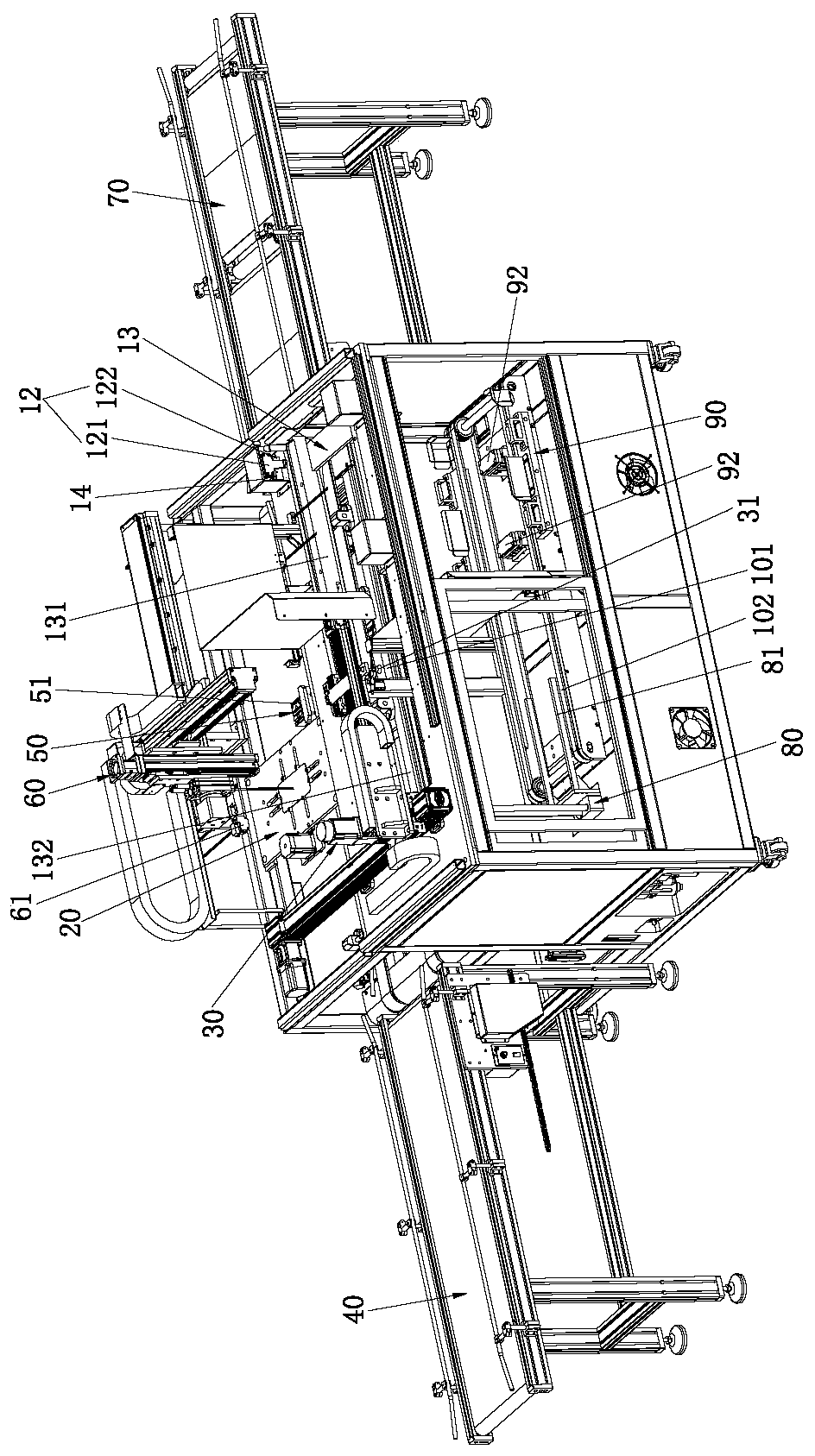

[0062] Please refer to Figure 1 to Figure 10 As shown, it has shown the concrete structure of the embodiment of the present invention; It is mainly used in the glass cover plate of mobile phone, but is not limited to the application of glass cover plate of mobile phone, also can be applied to other glass cover plates, below with its application The glass cover plate of the mobile phone is used for illustration; and, the structure of the tray 200 is as follows: Figure 9 As shown, the socket 300 and the mobile phone glass cover 400 are as figure 1 shown.

[0063] A fully automatic rack insertion machine for glass cover plates, comprising a first input mechanism for conveying trays, a positioning platform for positioning glass cover plates, a material retrieving mechanism, a second input mechanism for transporting insertion racks, The positioning mechanism for positioning inserts, the material shifting mechanism, the output mechanism for outputting inserts, the lifting and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com