Method for extracting ovotransferrin from pigeon eggs

A technology of ovotransferrin and pigeon eggs, which is applied in the direction of preparation methods of transferrin and peptides, chemical instruments and methods, etc., can solve the problems of low extraction rate, limitation of large-scale industrial production and extraction of ovotransferrin, and low purity problems, to achieve high extraction rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

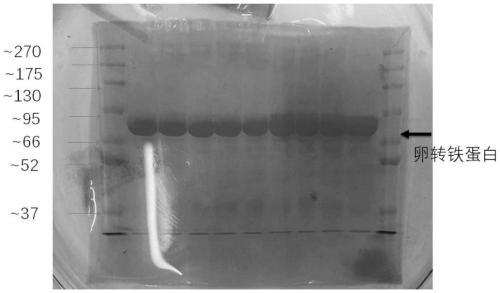

[0035] Embodiment 1 extracts the method for ovotransferrin from pigeon eggs

[0036] (1) Separate 200 g of egg white liquid from pigeon eggs, add 400 g of water to the egg white liquid for dilution, stir magnetically for 60 min, then centrifuge at 6000 r / min for 20 min at 4°C, filter with gauze, and take the supernatant;

[0037] (2) Then add FeCl to the supernatant 3 ·6H 2 O 3.24g, sodium bicarbonate 2.52g, sodium chloride 5.256g, then magnetically stirred for 120min;

[0038] (3) Add dehydrated ethanol to the supernatant again to make the ethanol volume concentration in the supernatant reach 43%, stir and homogeneously leave standstill for 30 min, and centrifuge to obtain precipitation 1 and filtrate;

[0039] (4) Continue adding absolute ethanol to the filtrate, so that the volume concentration of ethanol in the filtrate reaches 59%, stir evenly, let stand overnight, and centrifuge to obtain precipitate 2.

[0040] (5) Combine Precipitation 1 and Precipitation 2, wash wi...

Embodiment 2

[0041] Embodiment 2 extracts the method for ovotransferrin from pigeon eggs

[0042] (1) Separate 200 g of egg white liquid from pigeon eggs, add 300 g of water to the egg white liquid for dilution, stir magnetically for 70 min, then centrifuge at 5500 r / min for 25 min at 4°C, filter with gauze, and get the supernatant;

[0043] (2) Then add FeCl to the supernatant 3 ·6H 2 O 3.24g, sodium bicarbonate 2.52g, sodium chloride 5.256g, then magnetically stirred for 100min;

[0044] (3) adding dehydrated ethanol to the supernatant to make the volume concentration of ethanol in the supernatant reach 40%, stirring and homogenizing, leaving standstill for 30 min, and centrifuging to obtain the precipitate 1 and the filtrate;

[0045] (4) Continue adding absolute ethanol to the filtrate, so that the volume concentration of ethanol in the filtrate reaches 65%, stir evenly, let stand overnight, and centrifuge to obtain precipitate 2.

[0046] (5) Combine Precipitation 1 and Precipitati...

Embodiment 3

[0047] Embodiment 3 extracts the method for ovotransferrin from pigeon eggs

[0048] (1) Separate 200 g of egg white liquid from pigeon eggs, add 600 g of water to the egg white liquid to dilute, stir magnetically for 50 min, then centrifuge at 6500 r / min for 15 min at 4°C, filter with gauze, and take the supernatant;

[0049] (2) Then add FeCl to the supernatant 3 ·6H 2 O 3.24g, sodium bicarbonate 2.52g, sodium chloride 5.256g, then magnetically stirred for 150min;

[0050] (3) adding dehydrated ethanol to the supernatant to make the ethanol volume concentration in the supernatant reach 45%, stirring and homogenizing, leaving standstill for 30 min, and centrifuging to obtain the precipitate 1 and the filtrate;

[0051] (4) Continue adding absolute ethanol to the filtrate, so that the volume concentration of ethanol in the filtrate reaches 55%, stir evenly, let stand overnight, and centrifuge to obtain precipitate 2.

[0052] (5) Combine Precipitation 1 and Precipitation 2, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com