Modified PTFE composite dielectric material as well as preparation method and application thereof

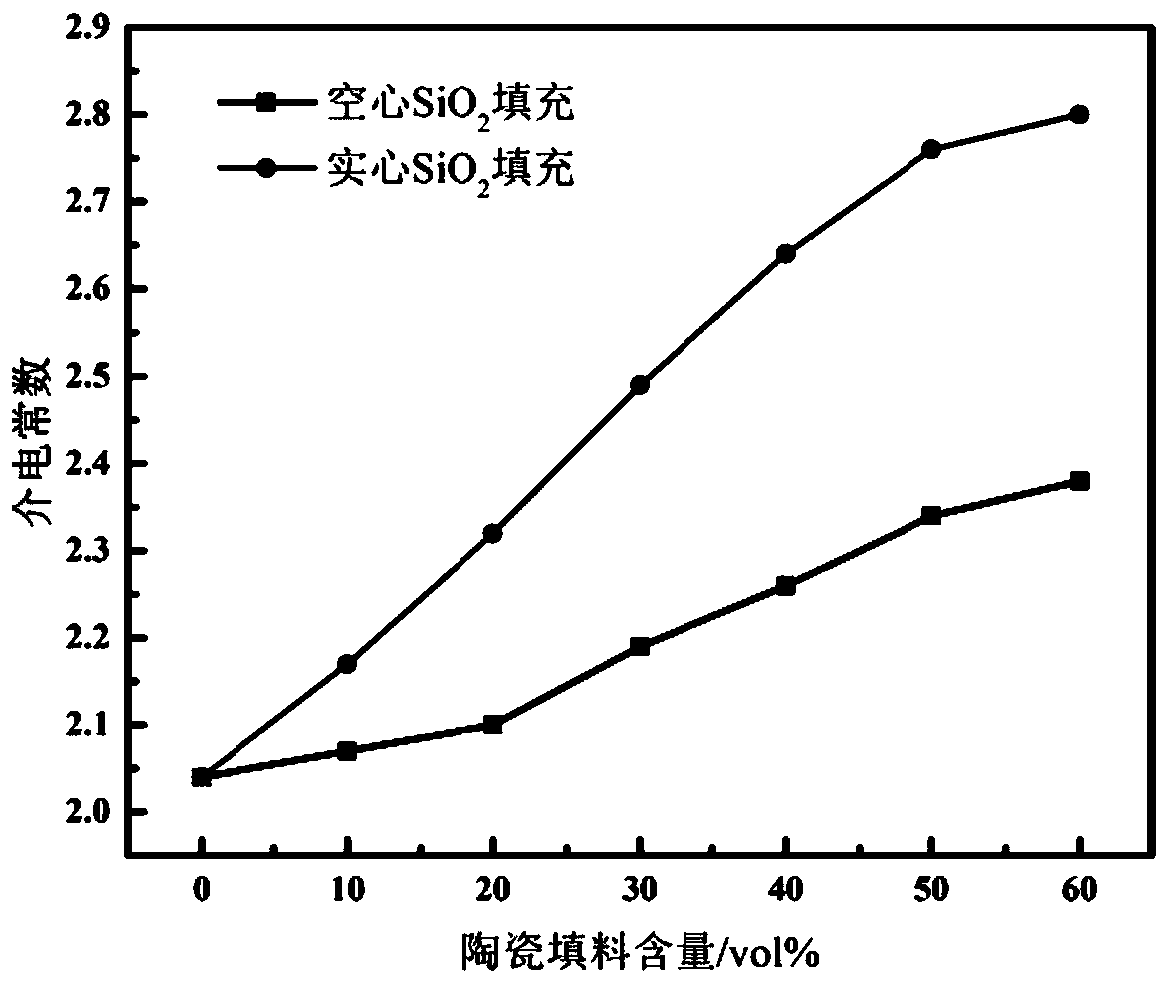

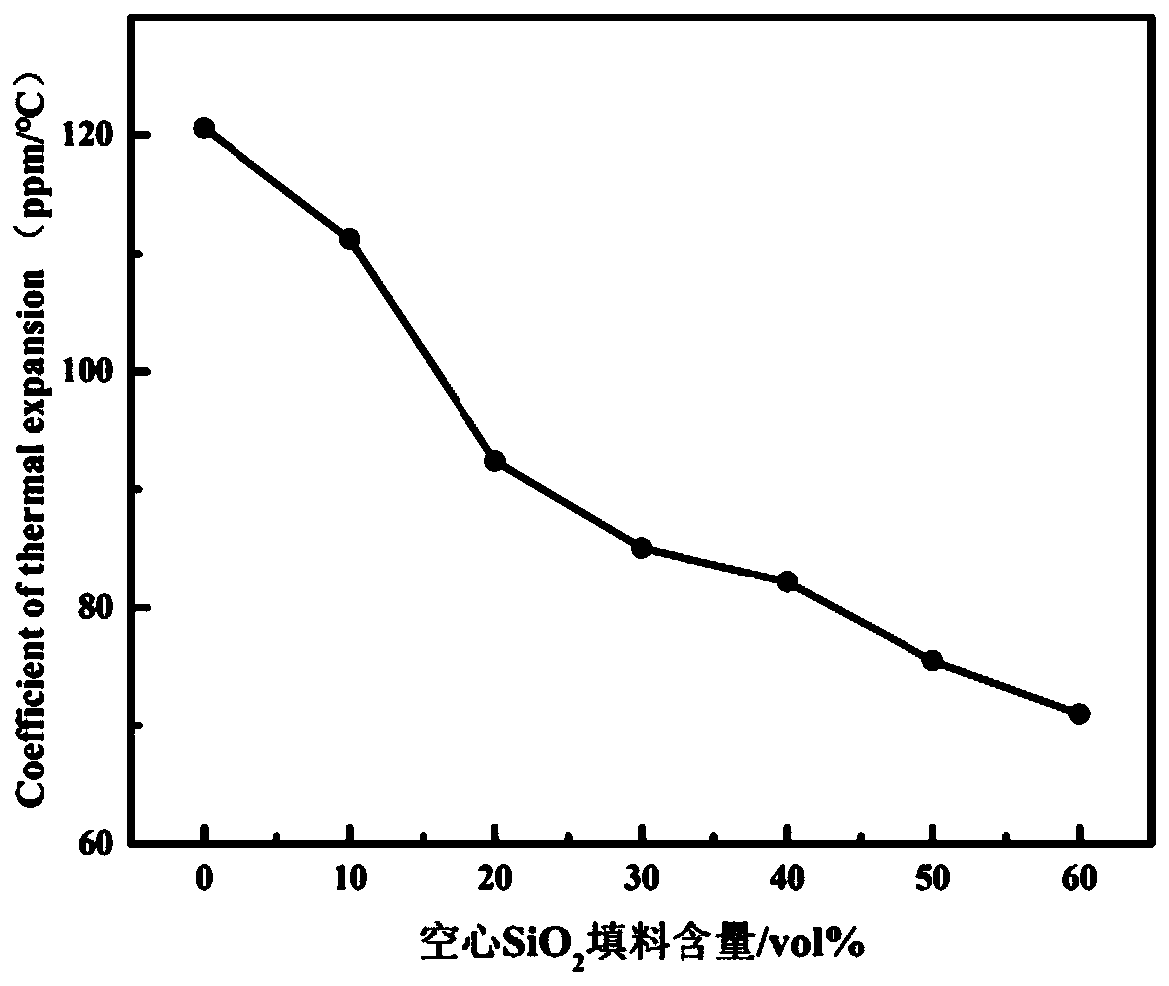

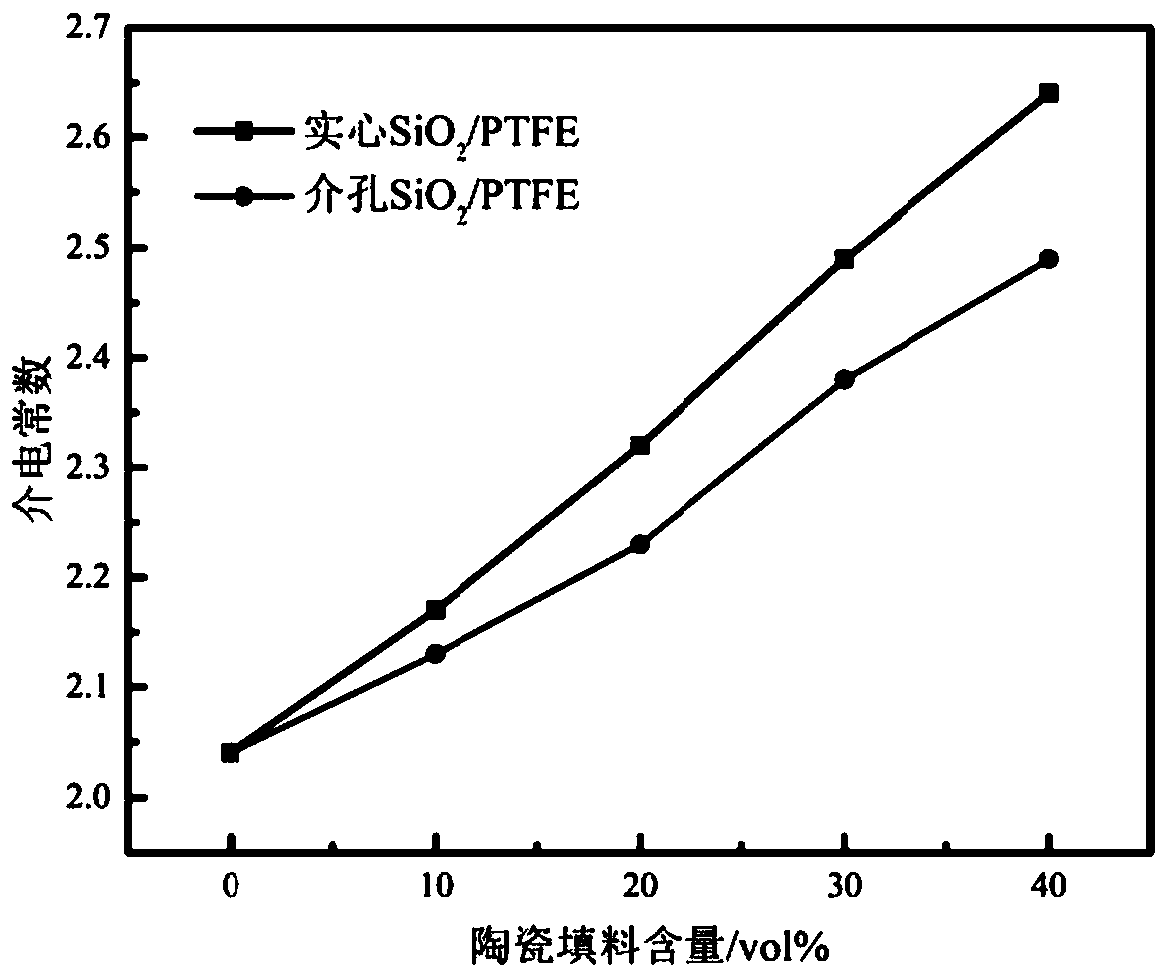

A technology of composite media and composite materials, which is applied in the field of modified PTFE composite materials, can solve the problems of high thermal expansion coefficient of PTFE, inability to obtain dielectric constant at the same time, and increase of dielectric constant, so as to achieve low dielectric constant and improve thermal expansion coefficient. Good, the effect of preventing the increase of dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Emulsion preparation: the hollow SiO 2 The ball and the PTFE emulsion are mixed, and double-center stirring is performed to control the ceramic particles to account for 10% of the total volume. The double-center stirring speed is 2000r / min, and the stirring time is 60s to obtain the emulsion for the PTFE composite dielectric plate containing ceramic fillers;

[0042] (2) Preparation of mud balls: add absolute ethanol with 50wt% of the emulsion quality to the emulsion obtained by mixing to carry out double-center stirring and demulsification, control the double-center stirring speed to be 800r / min, and control the double-center stirring time to be 50s to obtain ceramic-containing Mud balls for composite media boards filled with fillers;

[0043] (3) Calendering forming: The composite medium plate containing ceramic filler obtained by demulsification is pressed into a sheet by a calendering machine with mud balls. During the calendering process, the rotation speed of ...

Embodiment 2

[0049] Hollow SiO 2 Ball content is improved to 20%, and other raw materials and method steps, process parameter are identical with embodiment 1.

Embodiment 3

[0051] Hollow SiO 2 Ball content is improved to 30%, and other raw materials and method steps, process parameter are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com