Chamber washing device and method and semiconductor processing equipment

A technology for cleaning devices and chambers, which is used in gaseous chemical plating, metal material coating processes, coatings, etc., and can solve the problem of frequent use of plasma sources and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

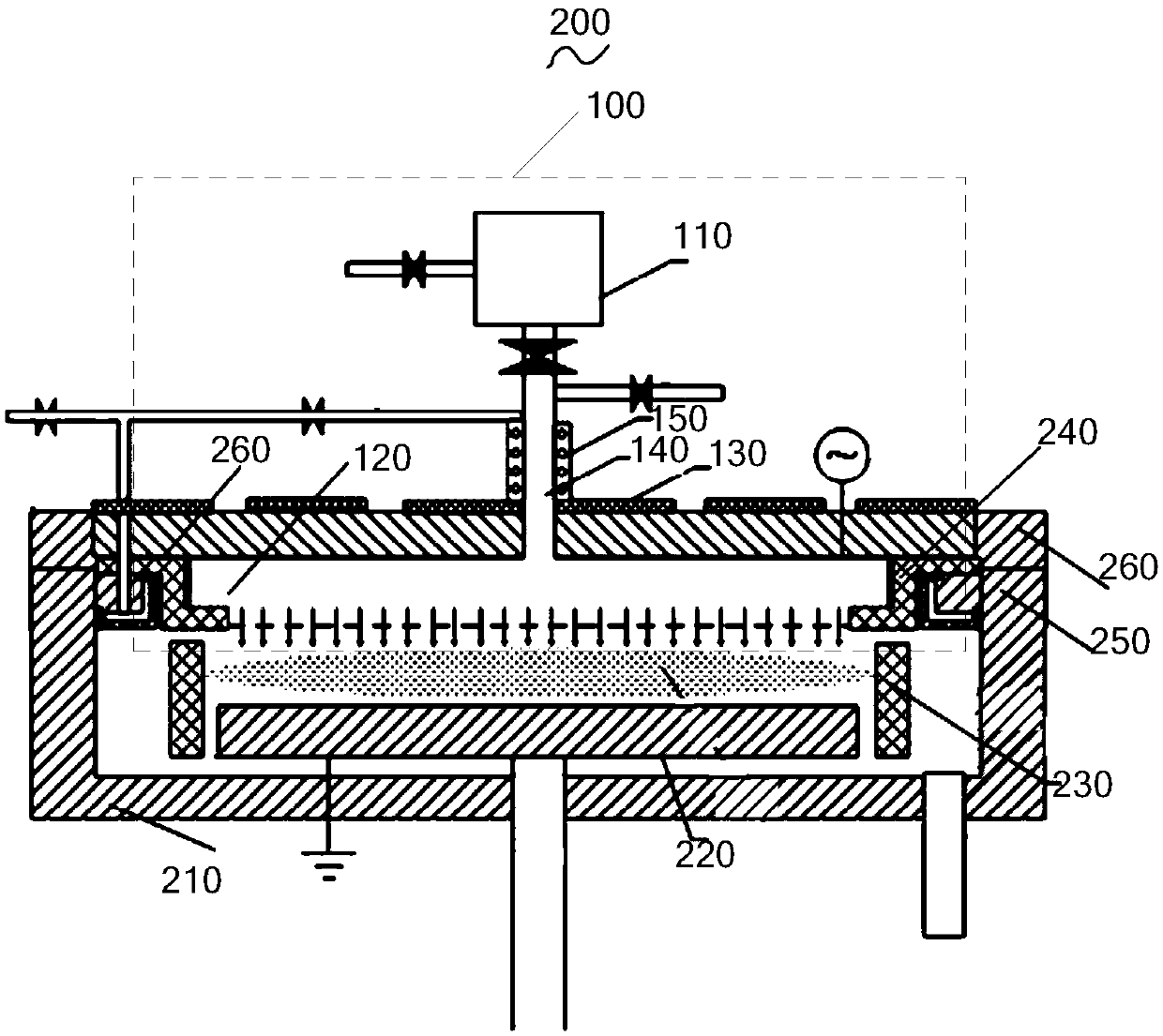

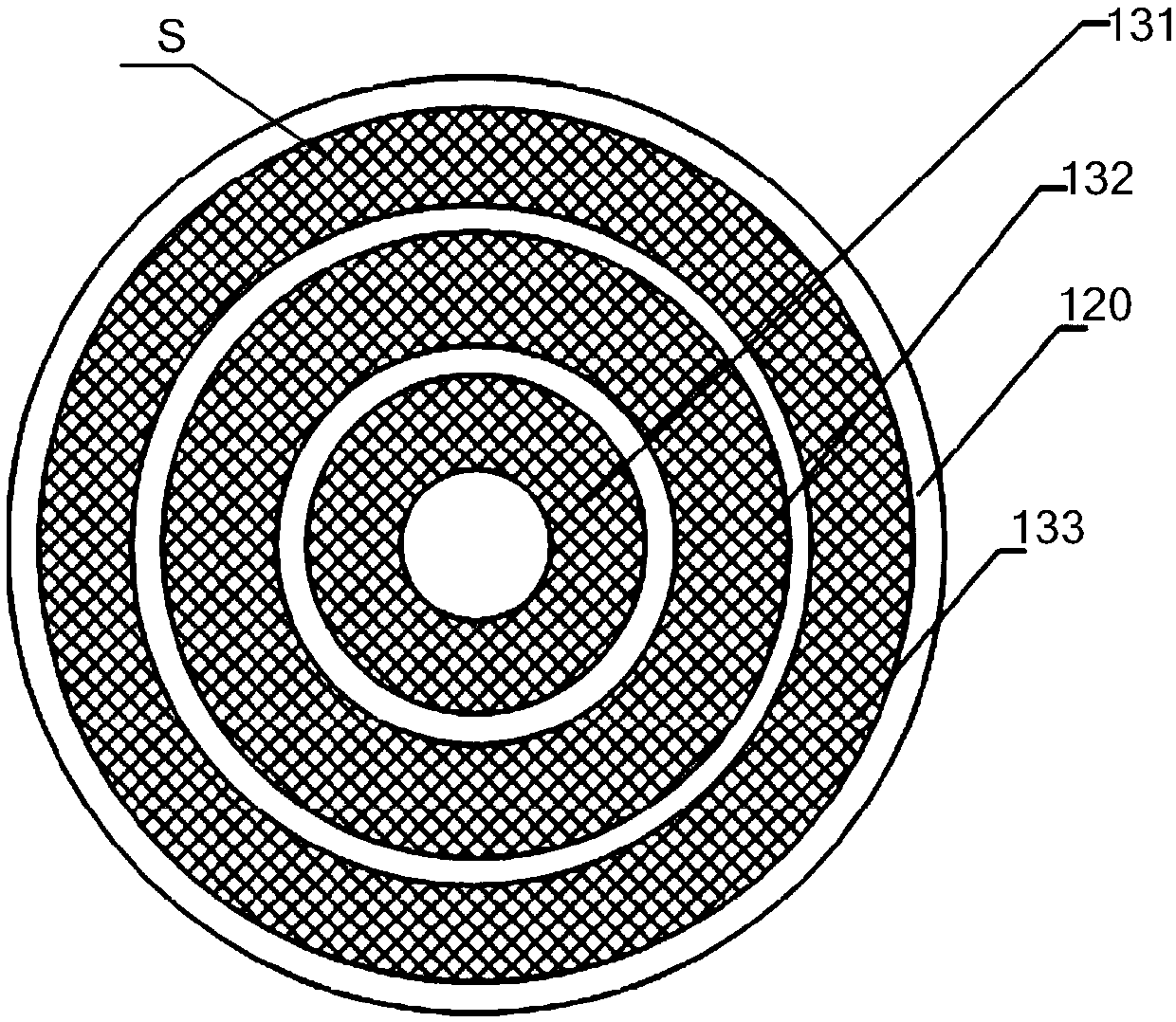

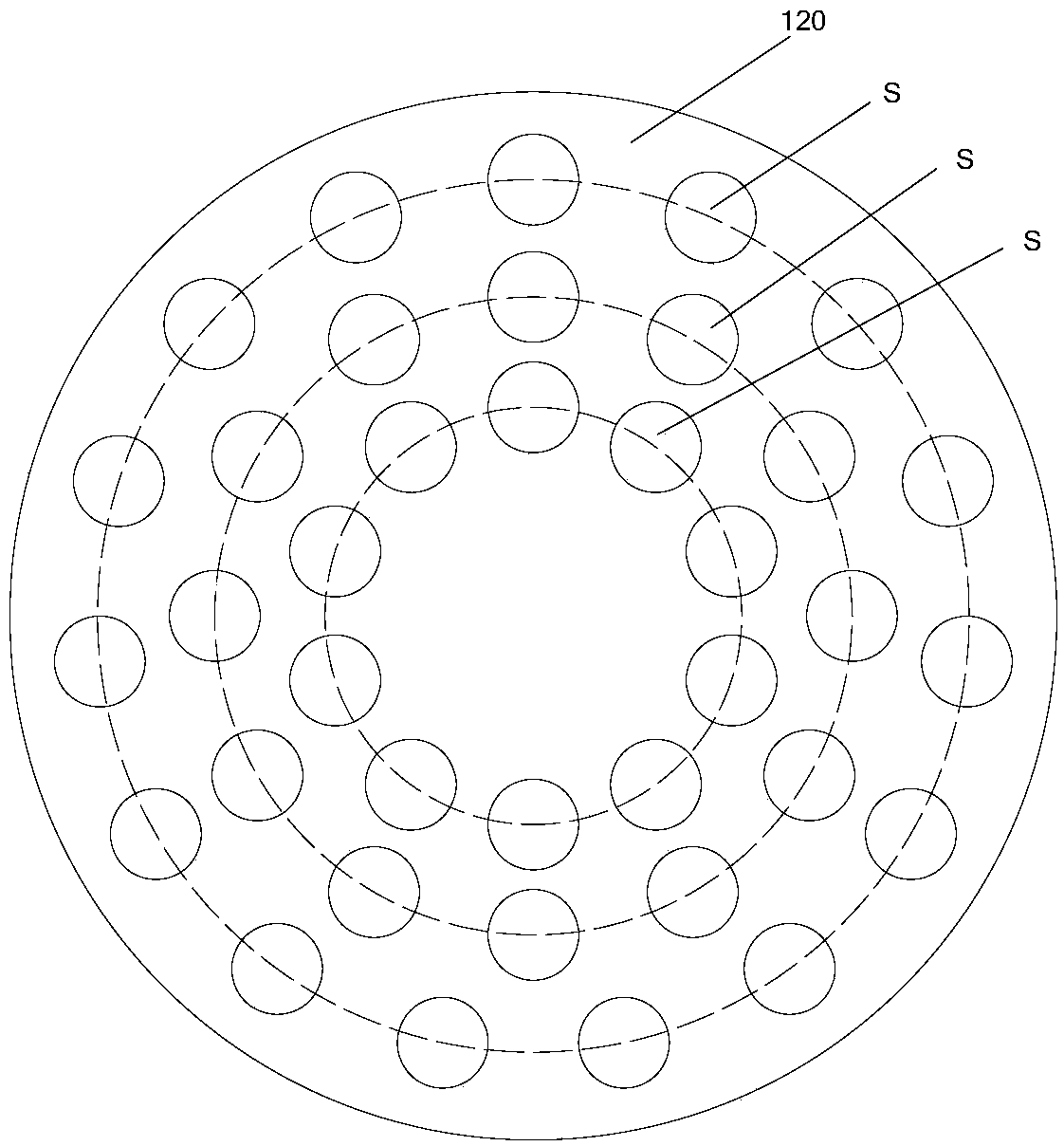

[0028] like figure 1 As shown, the first aspect of the present invention relates to a chamber cleaning device 100, the cleaning device 100 may include a cleaning plasma source 110 and a flow equalizer 120 connected to the cleaning plasma source 110, for example, cleaning plasma Source 110 may be connected to flow divider 120 via cleaning plasma source delivery line 140 as described below. The cleaning plasma source 110, for example, may be a remote plasma source (Remote Plasma Source, RPS), or may also be other structures capable of exciting cleaning gas to generate cleaning plasma. A number of uniform flow holes are generally arranged on the flow uniform memb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com