Metallographic display method of nickel-saving austenitic stainless steel

A technology for displaying austenitic stainless steel, applied in the preparation of test samples, etc., can solve the problems of poor corrosion effect and unclear grain boundary, and achieve good corrosion effect, easy to learn corrosion operation, and clear grain boundary Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] (1) Preparation of etchant

[0067] The corrosive agent is prepared from 8-12 parts by weight of oxalic acid, 2-4 parts by volume of hydrochloric acid, and 80-120 parts by volume of distilled water, wherein, when the unit of the parts by weight is gram, the unit of the parts by volume is milliliters ; When the unit of the parts by weight is kilogram, the unit of the parts by volume is liter; the consumption of each component can be enlarged or reduced in equal proportion.

[0068] a) Add 8-12 g of oxalic acid into 80-120 ml of distilled water, and keep stirring to mix evenly.

[0069] b) Pour 2-4ml hydrochloric acid into the prepared oxalic acid solution, stir and mix evenly.

[0070] (2) Metallographic corrosion method

[0071] a) The nickel-free austenitic stainless steel sample is made into a metallographic sample by rough grinding, fine grinding, polishing, cleaning and drying.

[0072] b) Take the prepared sample as the anode, fix it with galvanized tweezers and...

Embodiment 1

[0081] (1) Preparation of corrosive agent

[0082] First add 10g of oxalic acid into a beaker filled with 100ml of distilled water, stir evenly, then add 2ml of hydrochloric acid into the prepared oxalic acid solution, stir evenly to prepare a corrosion solution.

[0083] (2) Sample preparation

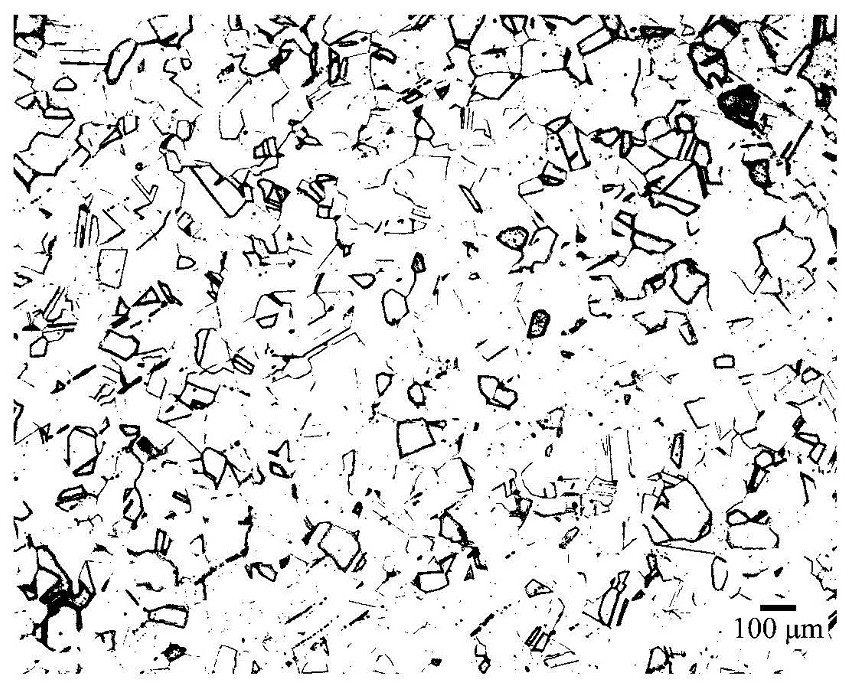

[0084] Grind and polish the test surface of the J3-section nickel-type austenitic stainless steel cold-rolled sample with 240#, 360#, 600#, 800#, 1000#, and 1200# water-grinding paper in turn after bright annealing to form a sample to be corroded, and then Rinse with distilled water, spray with alcohol and blow dry.

[0085] (3) Corrosion display

[0086] Fix the sample with tweezers and connect it to a DC power supply. The sample is connected to the positive pole, the aluminum plate is connected to the negative pole, the voltage is 20V, and the time is 50s. After the corrosion is over, cut off the power supply, remove the sample, rinse it with distilled water, then spray it with al...

Embodiment 2

[0088] (1) Preparation of corrosive agent

[0089] First add 8g of oxalic acid into a beaker filled with 90ml of distilled water, stir evenly, then add 3ml of hydrochloric acid into the prepared oxalic acid solution, stir evenly to prepare a corrosion solution.

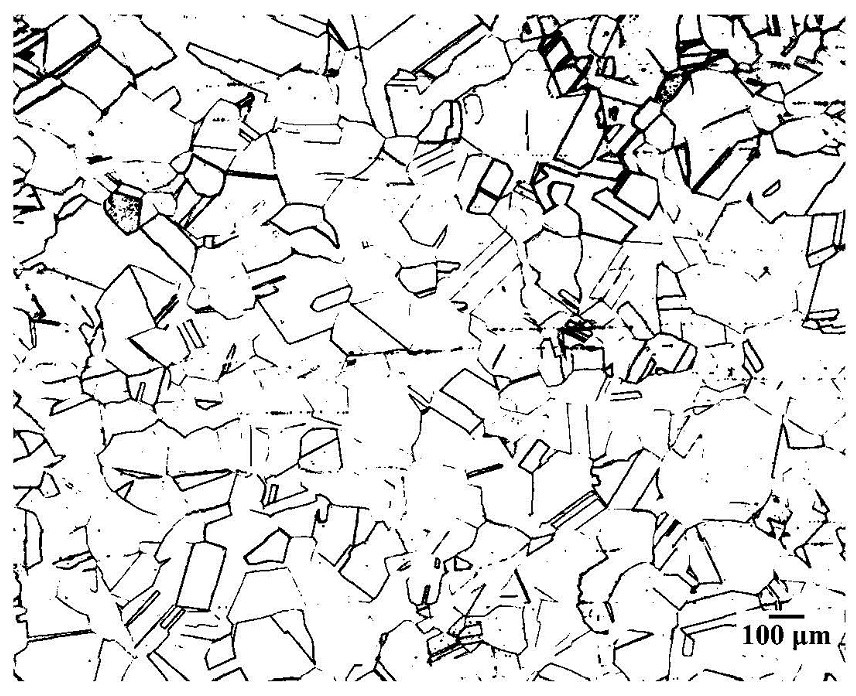

[0090] (2) Sample preparation

[0091] The test surface of the J3 section nickel-type austenitic stainless steel hot-rolled sample that has undergone solution treatment is ground and polished with 240#, 360#, 600#, 800#, 1000#, and 1200# water-grinding sandpaper in turn to form a sample to be corroded. Then rinse with distilled water, spray with alcohol and blow dry.

[0092] (3) Corrosion display

[0093] Fix the sample with tweezers and connect it to a DC power supply. The sample is connected to the positive pole, the aluminum plate is connected to the negative pole, the voltage is 25V, and the time is 45s. After the corrosion is over, cut off the power supply, remove the sample, rinse it with distilled water, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com