Yarn-based threading needle block hot-pressing rolling online stain removing machine

A needle block and threading technology, applied in heating, mechanical cleaning, high-pressure cleaning, etc., can solve the problems of interfering with the color of non-woven fabrics, bacteria cannot be cleaned, rework, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

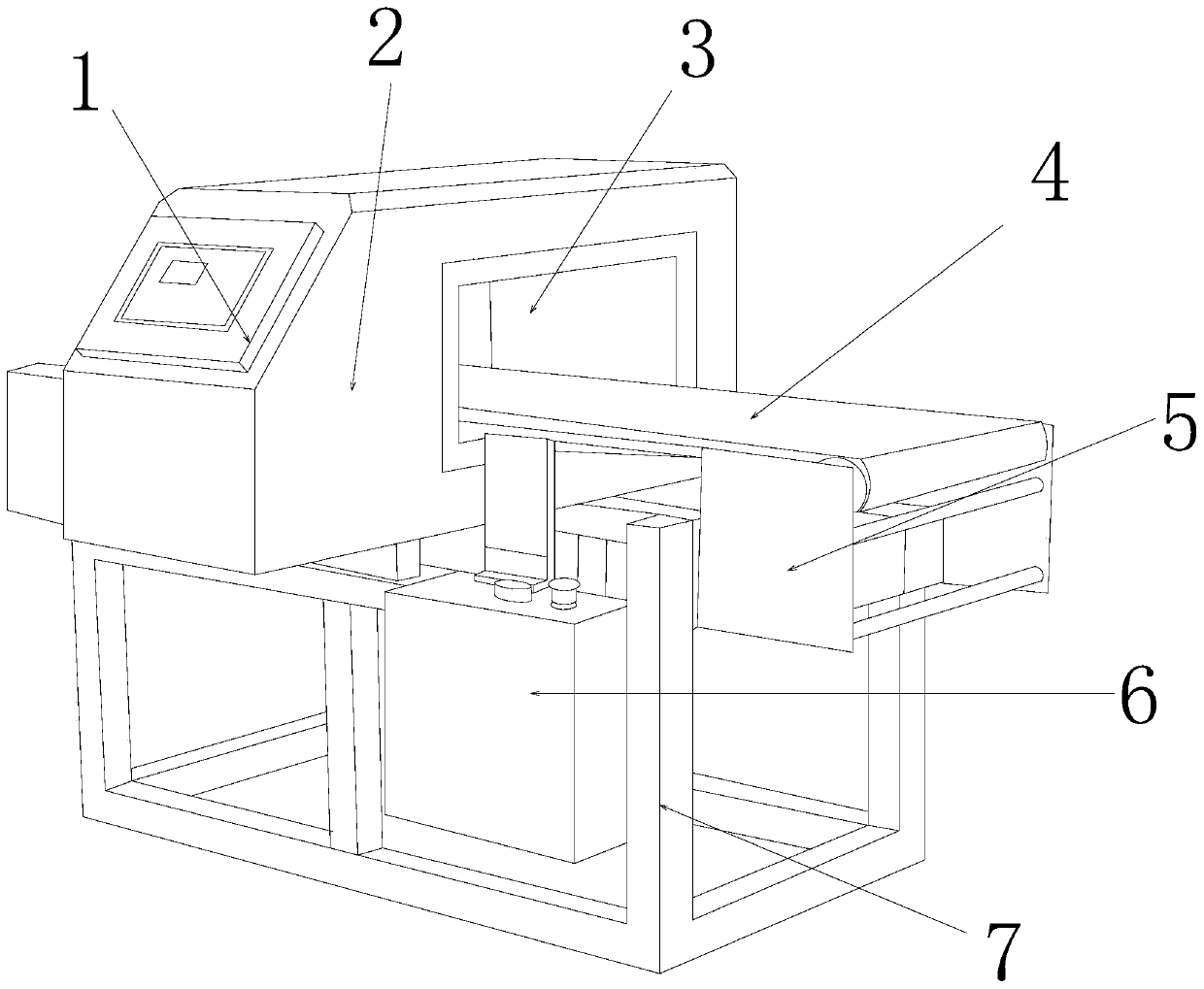

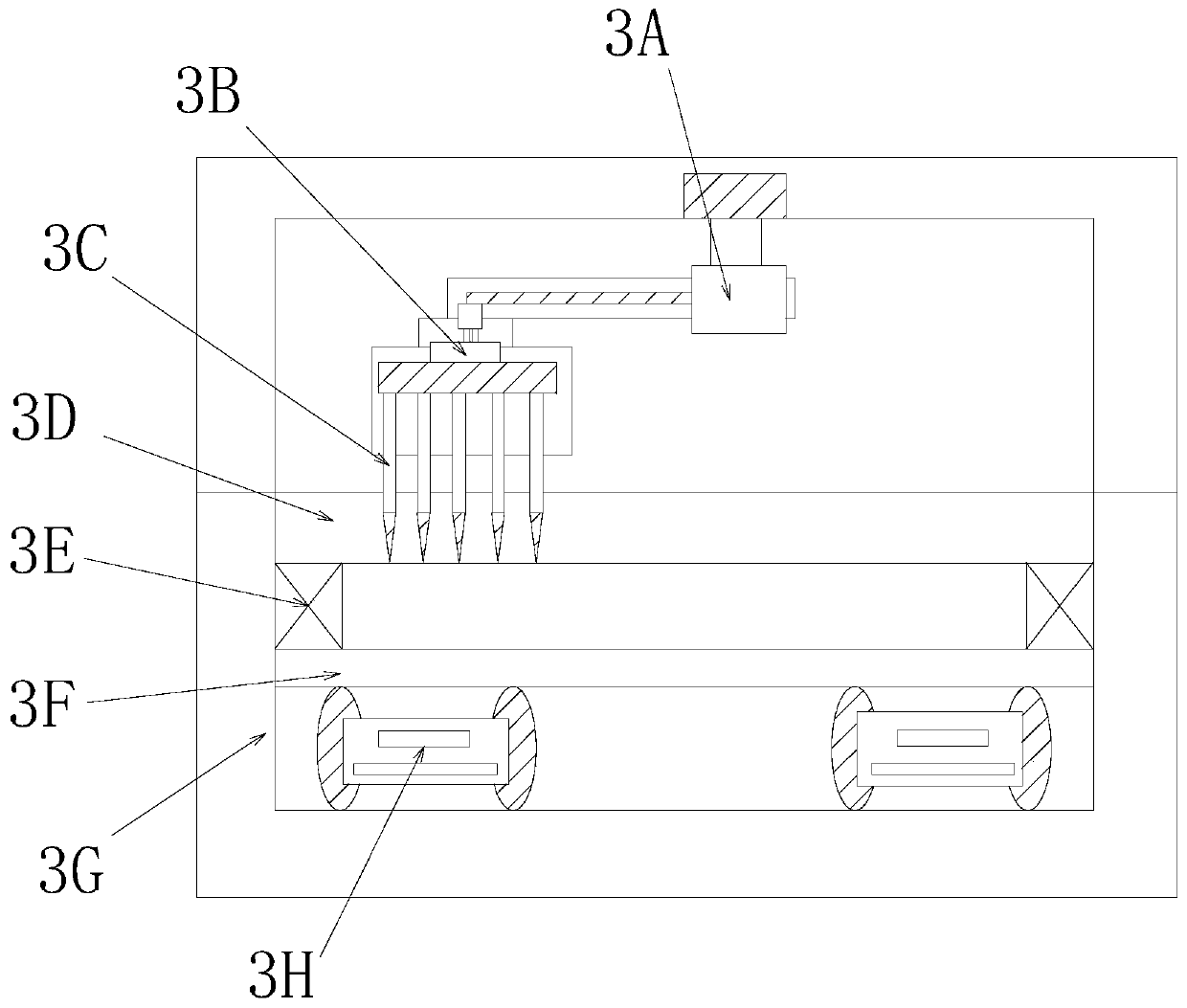

[0033] see Figure 1-Figure 7, the present invention provides an online stain removal machine based on threading needle block hot-press coiling of yarn, its structure includes: industrial control panel 1, power distribution box 2, inner groove 3 of hot-press needle block, non-woven fabric guide belt 4. Motor frame 5, start-stop battery box 6, bottom rod support seat 7, the industrial control panel 1 is electrically connected to the power distribution box 2, and the power distribution box 2 is nested into one body with the inner groove 3 of the hot-pressing needle block And on the same vertical plane, the inner groove 3 of the hot pressing needle block is mechanically connected with the motor frame 5 through the non-woven fabric guide belt 4 and is on the same horizontal plane, and the motor frame 5 is electrically connected to the start-stop battery box 6 through wires. connection, the start-stop battery box 6 is closely attached to the front side of the bottom bar support sea...

Embodiment 2

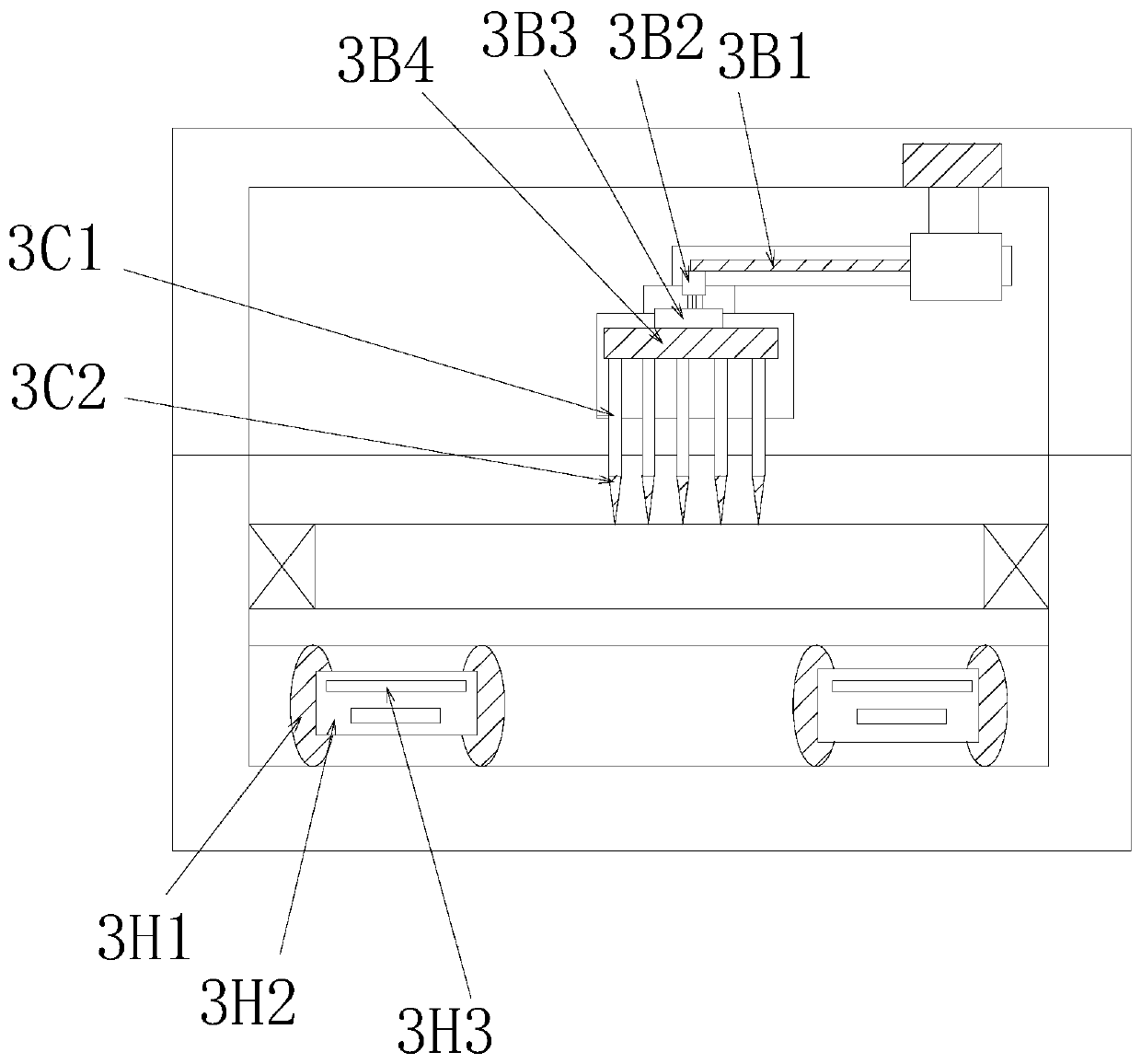

[0040] see Figure 1-Figure 7 , the present invention provides an online stain removal machine based on threading type needle block hot-press coiling of yarn, other aspects are the same as embodiment 1, the difference is:

[0041] see image 3 , the arc plate support tube 3H is composed of a flat pad wheel 3H1, a roller tube groove 3H2, and an arc brace bending plate 3H3, and two flat pad wheels 3H1 are respectively nested on the left and right sides of the roller tube groove 3H2, The brace bending plate 3H3 is installed inside the roller tube groove 3H2 and the axes are collinear, and the flat washer 3H1 elastically pushes the yarn on both sides of the roller tube groove 3H2 to form a cooperative linkage effect of rolling and conveying.

[0042] see Figure 7 , the arc brace bending plate 3H3 is composed of a thick-wall column tube 3H31, a clip seat 3H32, a segmented groove bend plate 3H33, and a counterweight bottom bar 3H34. The section groove curved plates 3H33 are fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com