Method for analyzing SEBS hydrogenation degree of butadiene styrene rubber by using nuclear magnetic resonance technology

A technology of styrene-butadiene rubber and nuclear magnetic resonance, which is applied in the direction of analysis by nuclear magnetic resonance, material analysis through resonance, and material analysis. It can solve the problem of long analysis period and the analysis and detection of hydrogenation degree of styrene-butadiene rubber products and other issues, to achieve the effect of improving economic benefits, good environmental protection benefits, and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Analysis of hydrogenation degree of styrene-butadiene rubber SEBS (sample 1)

[0041] 1. Sample Analysis

[0042] Taking the styrene-butadiene rubber SEBS product of a domestic chemical company (sample 1, w% (styrene) = 34%, w% (butadiene) = 66%, hydrogenation reaction for about 10 minutes under certain conditions) as an example, the The analysis process of its degree of hydrogenation is described, and the steps are as follows:

[0043] (1) Add the analysis sample to the NMR tube.

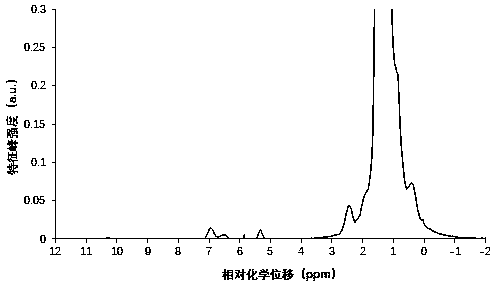

[0044] (2) Place the NMR tube in the NMR analyzer, select the corresponding analysis plan, scan the sample, and obtain the H NMR spectrum of the sample (as attached figure 1 shown);

[0045] (3) Integrate the characteristic peak areas in the two regions of 6.23-7.28ppm and 5.01-5.50ppm in the sample hydrogen NMR spectrum, and calculate the characteristic peak areas S in the two regions 1 , S 2 are 0.3101 and 0.1012 respectively, then according to the hydrogenation degree calculation for...

Embodiment 2

[0052] Analysis of hydrogenation degree of styrene-butadiene rubber SEBS (sample 2)

[0053] 1. Sample Analysis

[0054] Taking another styrene-butadiene rubber SEBS product of a domestic chemical company (sample 2, w% (styrene) = 34%, w% (butadiene) = 66%, hydrogenation reaction for about 20 minutes under certain conditions) as an example, The analysis process of its degree of hydrogenation is described, and the steps are as follows:

[0055] (1) Add the analysis sample to the NMR tube.

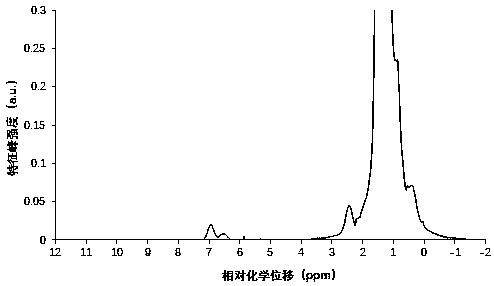

[0056] (2) Place the NMR tube in the NMR analyzer, select the corresponding analysis plan, scan the sample, and obtain the H NMR spectrum of the sample (as attached figure 2 shown);

[0057] (3) Integrate the characteristic peak areas in the two regions of 6.23-7.28ppm and 5.01-5.50ppm in the sample hydrogen NMR spectrum, and calculate the characteristic peak areas S in the two regions 1 , S 2 are 0.4199 and 0.0340 respectively, then according to the hydrogenation degree calculation fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com