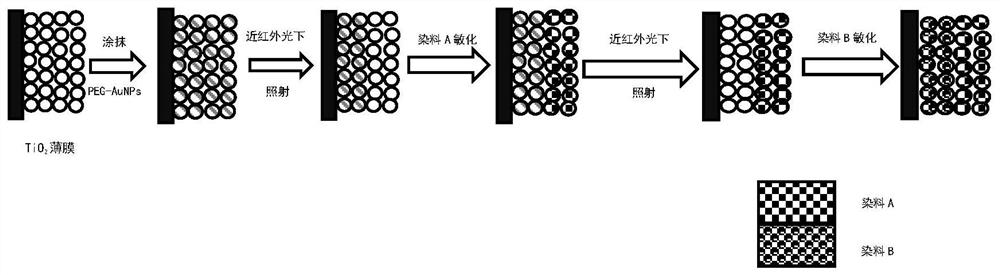

A method of preparing multi-layer co-sensitized film by light control technology

A technology of co-sensitization and light control, applied in the field of electrochemistry, can solve the problem that the dye adsorption depth is difficult to control, and achieve good light-to-heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: On TiO 2 Apply PEG-AuNPs on the film and irradiate with two kinds of near-infrared light with different powers (such as 50mW and 1200mW), and irradiate for the same time under the same conditions. It can be found that the thicker the thickness of the blank layer obtained by using a higher power light source .

Embodiment 2

[0026] Example 2: On TiO 2 Apply PEG-AuNPs on the film, and use the same near-infrared light source to irradiate for different times (for example, 5 minutes and 10 minutes). It can be found that under near-infrared light irradiation, the longer the irradiation time, the thicker the blank layer obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com