Ion implantation method and ion implantation system

An ion implantation system and ion implantation technology, applied in the field of ion implantation methods and ion implantation systems, can solve problems affecting the electrical properties and yield of devices, and achieve the elimination of the impact caused by ion implantation effects, uniform electrical properties, and better uniformity electrical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

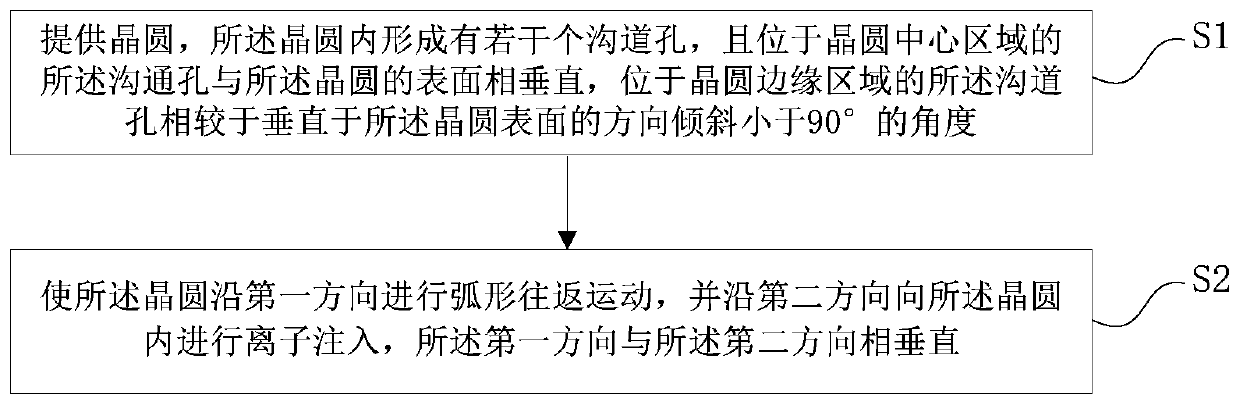

[0041] see figure 1 , the present embodiment also provides an ion implantation method, the ion implantation method includes the following steps:

[0042] 1) A wafer is provided, and several channel holes are formed in the wafer, and the communication holes located in the central area of the wafer are perpendicular to the surface of the wafer, and the channels located in the edge area of the wafer the holes are inclined at an angle of less than 90° relative to a direction perpendicular to the wafer surface; and

[0043] 2) making the wafer reciprocate in an arc along a first direction, and perform ion implantation into the wafer along a second direction, the first direction being perpendicular to the second direction.

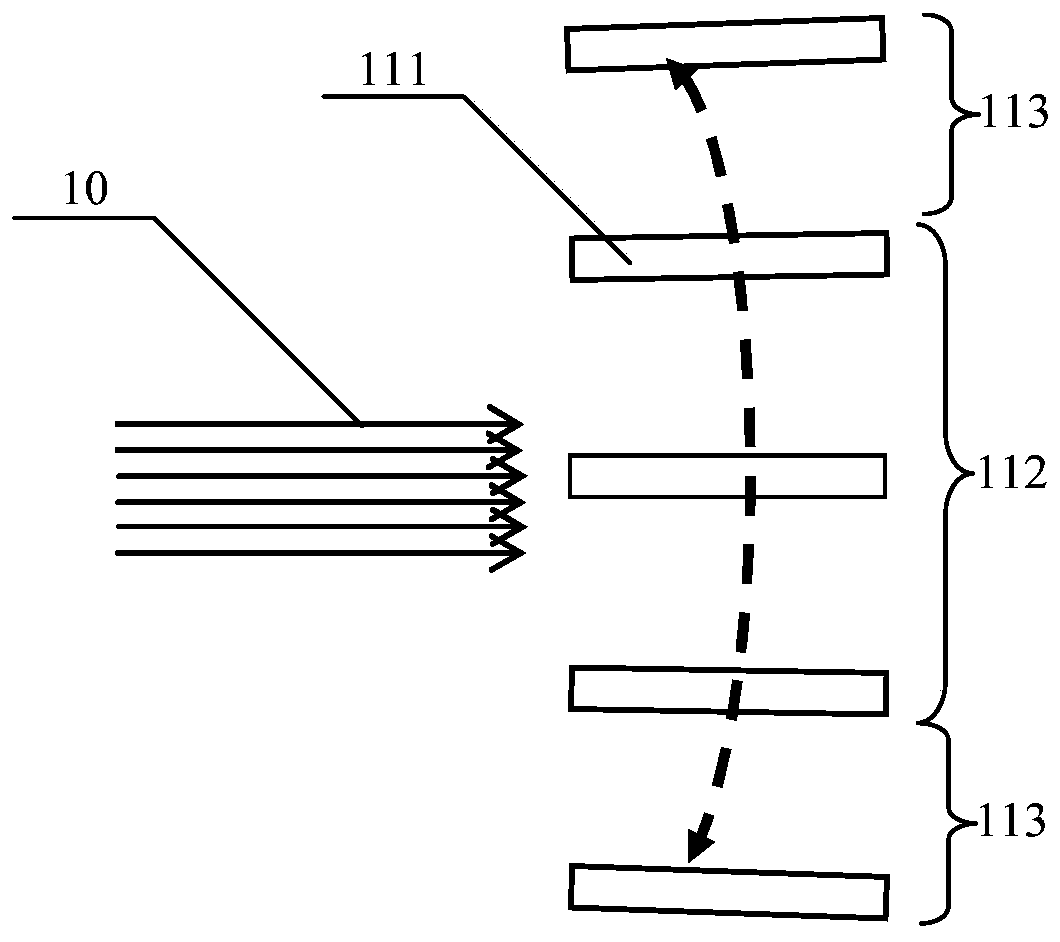

[0044] In step 1), see figure 1 Step S1 in and figure 2 , a wafer is provided, and several channel holes 111 are formed in the wafer, and the communication holes 111 located in the central region 112 of the wafer are perpendicular to the surface of the w...

Embodiment 2

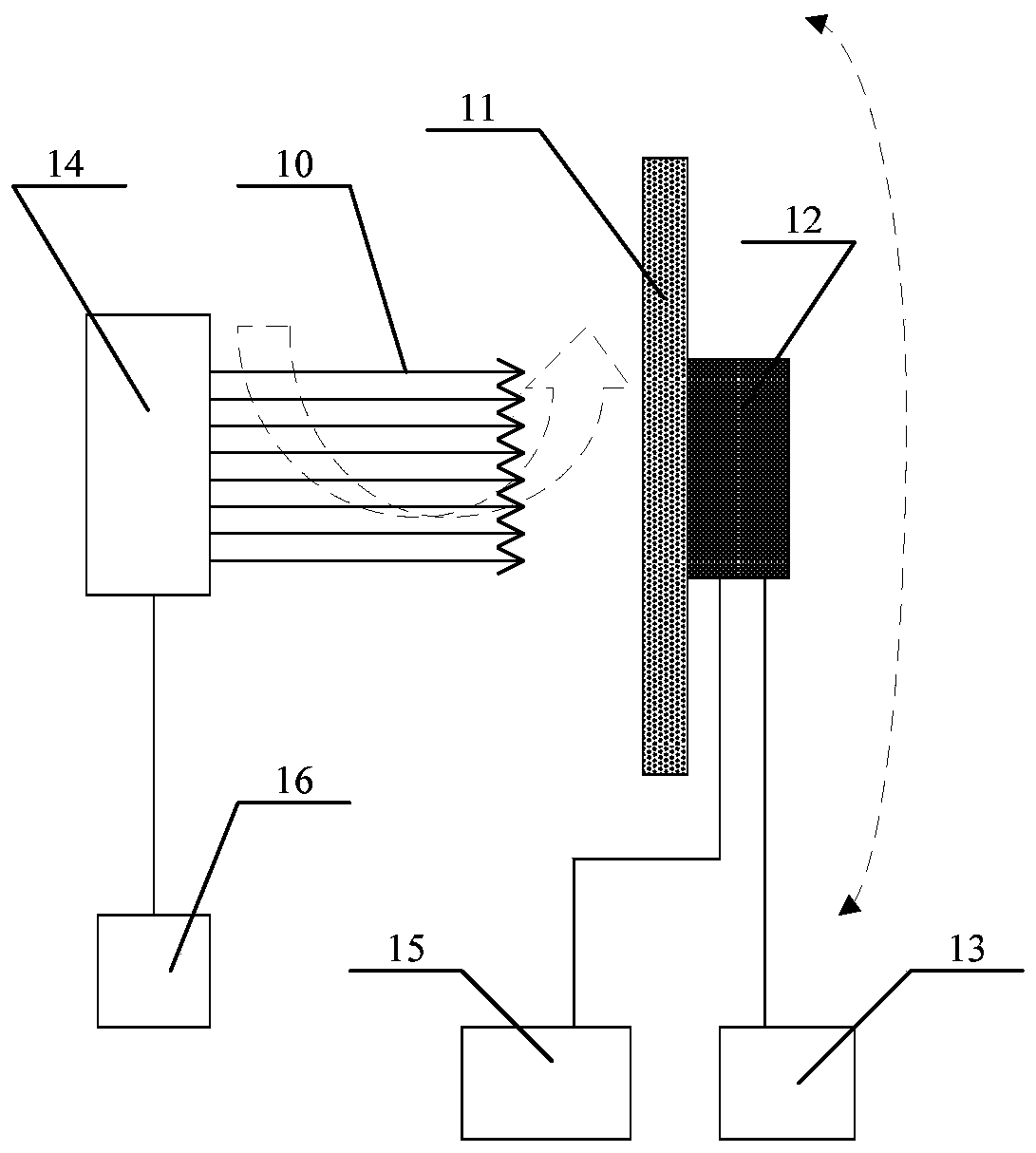

[0065] Please combine Figure 1 to Figure 2 refer to image 3 , an ion implantation system is also provided in this embodiment, and the ion implantation system includes: a wafer chuck 12, the wafer chuck 12 is used to absorb the wafer 11, and several channels are formed in the wafer 11 hole 111, and the communication hole 111 located in the wafer center area 112 is perpendicular to the surface of the wafer 11, and the channel hole 111 located in the wafer edge area 113 is compared to the channel hole 111 perpendicular to the wafer 11 The direction of the surface is inclined at an angle less than 90°; the first driving device 13, the first driving device 13 is connected with the wafer chuck 12, and the first driving device is used to drive the wafer chuck 12 to drive the wafer chuck 12 The wafer 11 performs an arc-shaped reciprocating movement along a first direction; and an ion implantation device 14, the ion implantation device 13 performs ion implantation into the wafer 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com