A kind of formation method of lithium ion battery

A technology of lithium-ion battery and chemical formation method, which is applied in the direction of secondary battery, electrochemical generator, secondary battery maintenance/maintenance, etc. It can solve the problems that the performance of additives is difficult to exert, affect the battery cycle life, and the effect is difficult to be improved. Achieve the effects of avoiding cycle life decline, avoiding excessive temperature rise, and avoiding voltage polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

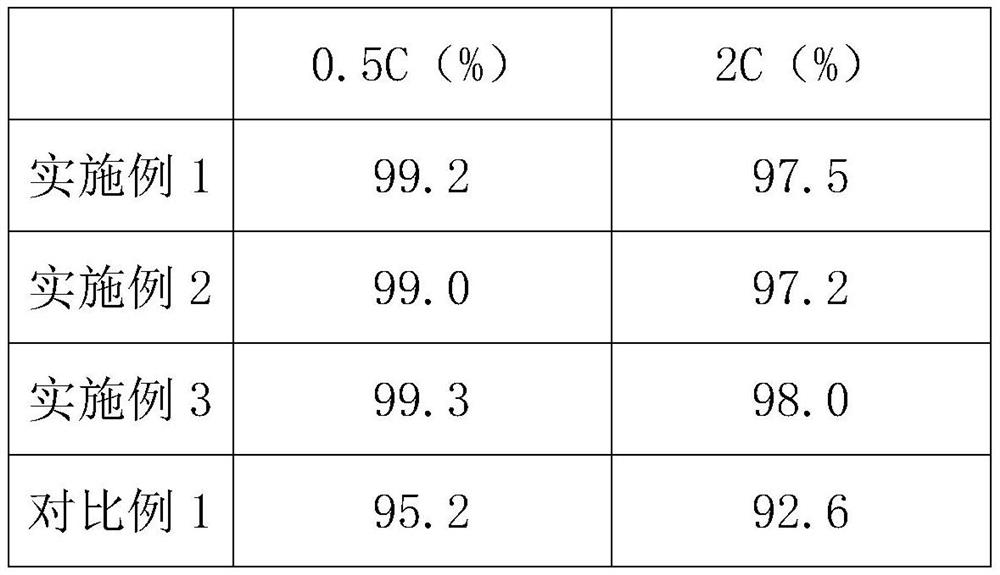

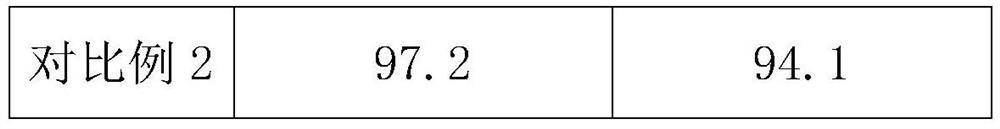

Examples

Embodiment 1

[0030]1) Composition the negative electrode and the lithium sheet to the experimental cell, placed in the first electrolyte, the first electrolyte contains 1% FEC and 4% VC;

[0031]2) A current constant flow of 0.01c to 0.3V, then discharged from 0.1c to 0.1V, then charge the current constant flow of 0.1c to 0.3V, then charge it to 0.8V at 0.01c constant current ; Repeat the above process 3 times;

[0032]3) Adjust the experimental battery voltage of 0.8V until the charging current is below 0.01c;

[0033]4) Remove the negative electrode, constitute a battery with the positive electrode and the diaphragm to implant the second electrolyte;

[0034]5) Charged from 0.05 C to 3.4 V, constant pressure under this voltage until the charging current is below 0.01c;

[0035]6) Charged by a current constant flow of 0.1 C to 3.7V, charged under the voltage until the charging current is below 0.01c;

[0036]7) Adjust the battery temperature of 5 degrees Celsius;

[0037]8) Pulse charge, the pulse current is 0.1c, ...

Embodiment 2

[0041]1) Composition the negative electrode and the lithium sheet to the experimental cell, placed in the first electrolyte, containing a volume fraction of 3% FEC and 1% VC;

[0042]2) A current constant flow of 0.05c to 0.3V, then discharged from 0.5c current constant flow charge, then charge to 0.3V at a current of 0.5C, then charge it to 0.8V at 0.05c constant current ; Repeat the above process 3 times;

[0043]3) Adjust the experimental battery voltage of 0.8V until the charging current is below 0.01c;

[0044]4) Remove the negative electrode, constitute a battery with the positive electrode and the diaphragm to implant the second electrolyte;

[0045]5) Charged by a current constant flow of 0.1 C to 3.5V, and the constant pressure is charged under the voltage until the charging current is below 0.01c;

[0046]6) Charged by a current constant flow of 0.2 C to 3.8V, and the constant pressure is charged under the voltage until the charging current is below 0.01c;

[0047]7) Adjust the battery temp...

Embodiment 3

[0052]1) Composition of the negative electrode and the lithium sheet to the experimental cell, placed in the first electrolytic solution, containing a volume fraction of 2% of the FEC and 3% VC;

[0053]2) A current constant flow of 0.02c to 0.3V, then discharged from 0.2 C to 0.1V, then charge the current constant flow of 0.2c to 0.3V, then charge it to 0.8V at 0.02C. ; Repeat the above process 3 times;

[0054]3) Adjust the experimental battery voltage of 0.8V until the charging current is below 0.01c;

[0055]4) Remove the negative electrode, constitute a battery with the positive electrode and the diaphragm to implant the second electrolyte;

[0056]5) Charged by a current constant flow of 0.08c to 3.5V, and the constant pressure is charged under the voltage until the charging current is below 0.01c;

[0057]6) Charged by a current constant flow of 0.15c to 3.75 V, constant pressurized under the voltage until the charging current is below 0.01c;

[0058]7) Adjust the battery temperature of 10 deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com