Method and apparatus for examining measurement tip of scanning probe microscope

A scanning probe and microscope technology, used in scanning probe microscopy, scanning probe technology, measuring devices, etc. The effect of reducing the outline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

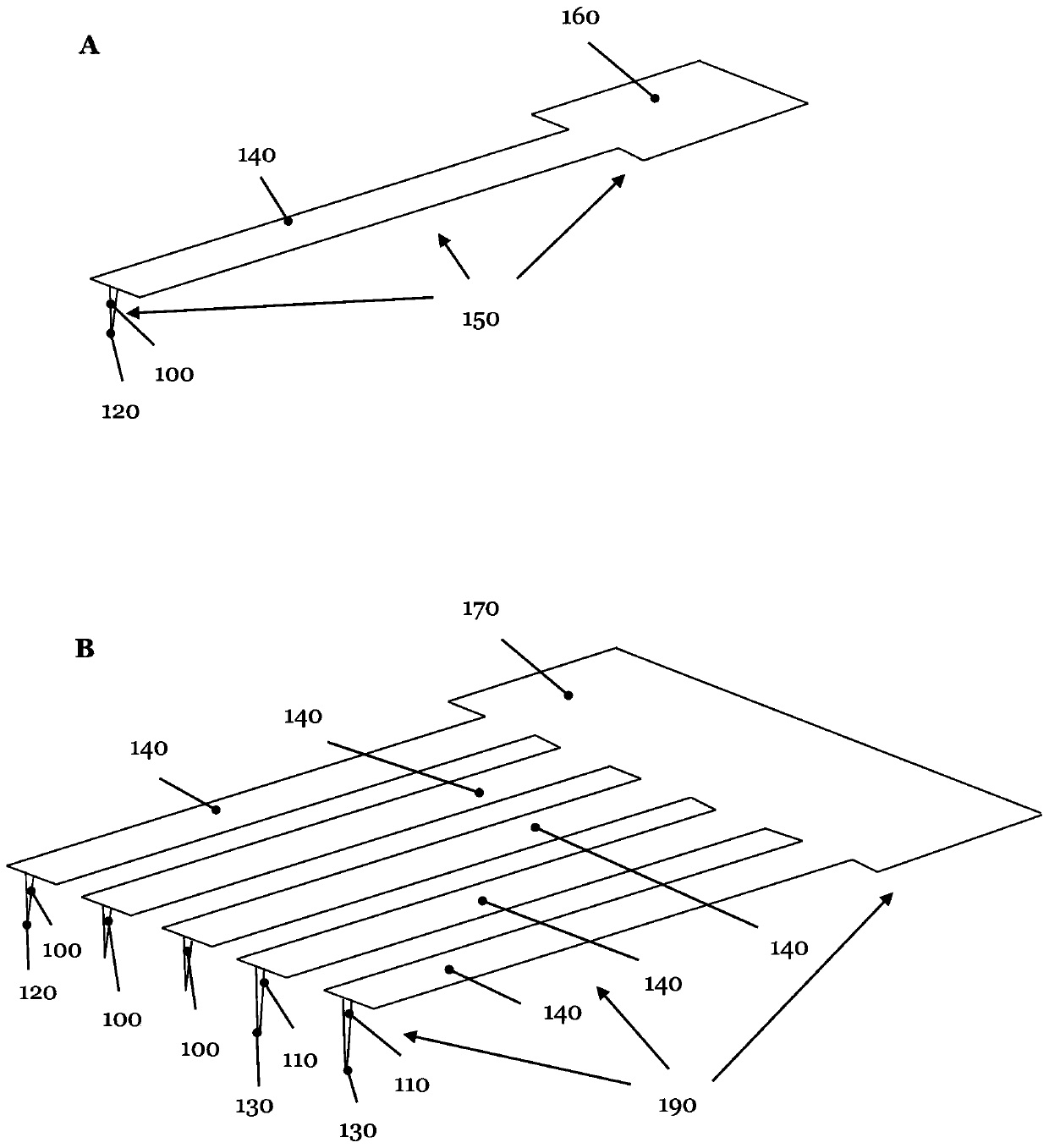

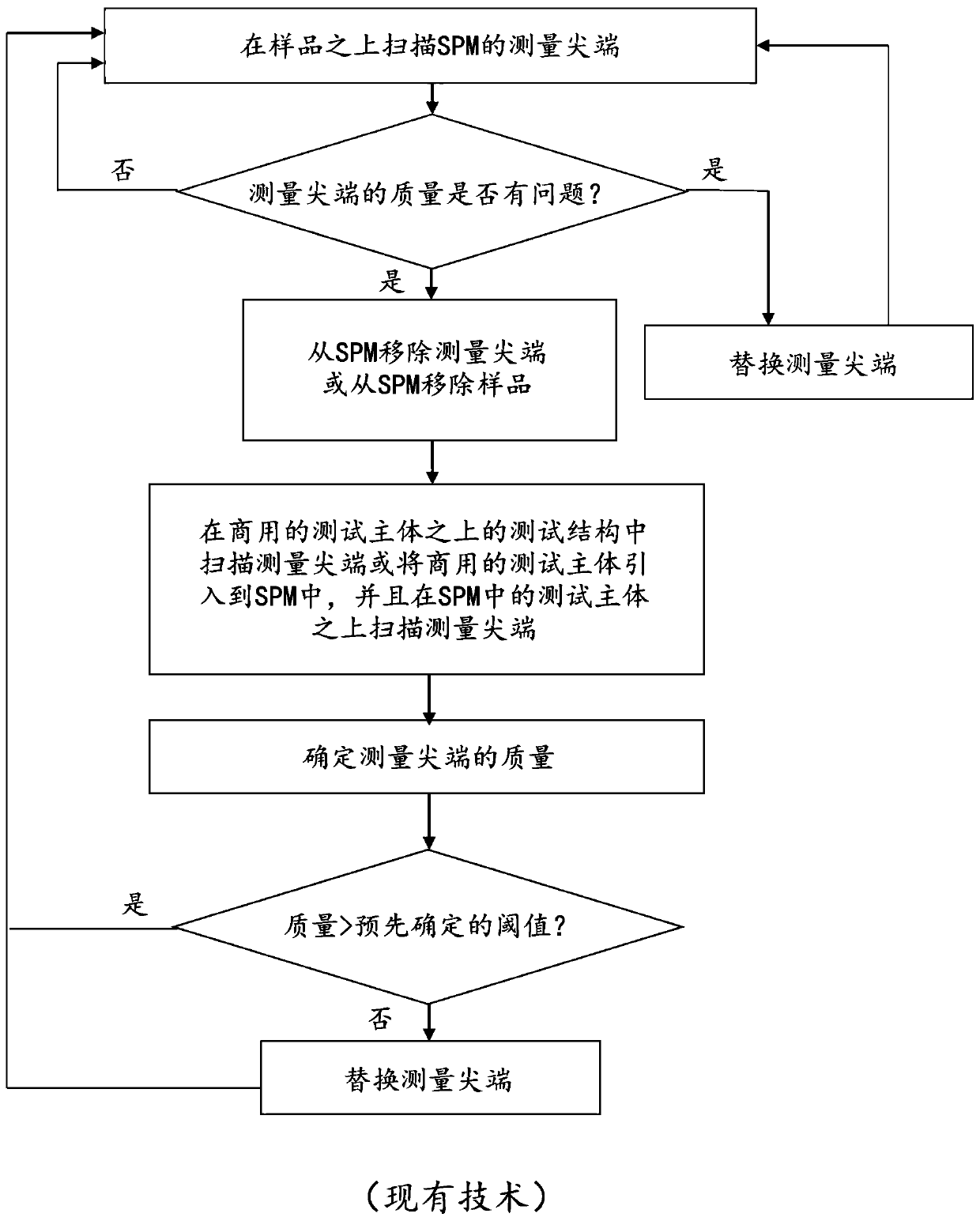

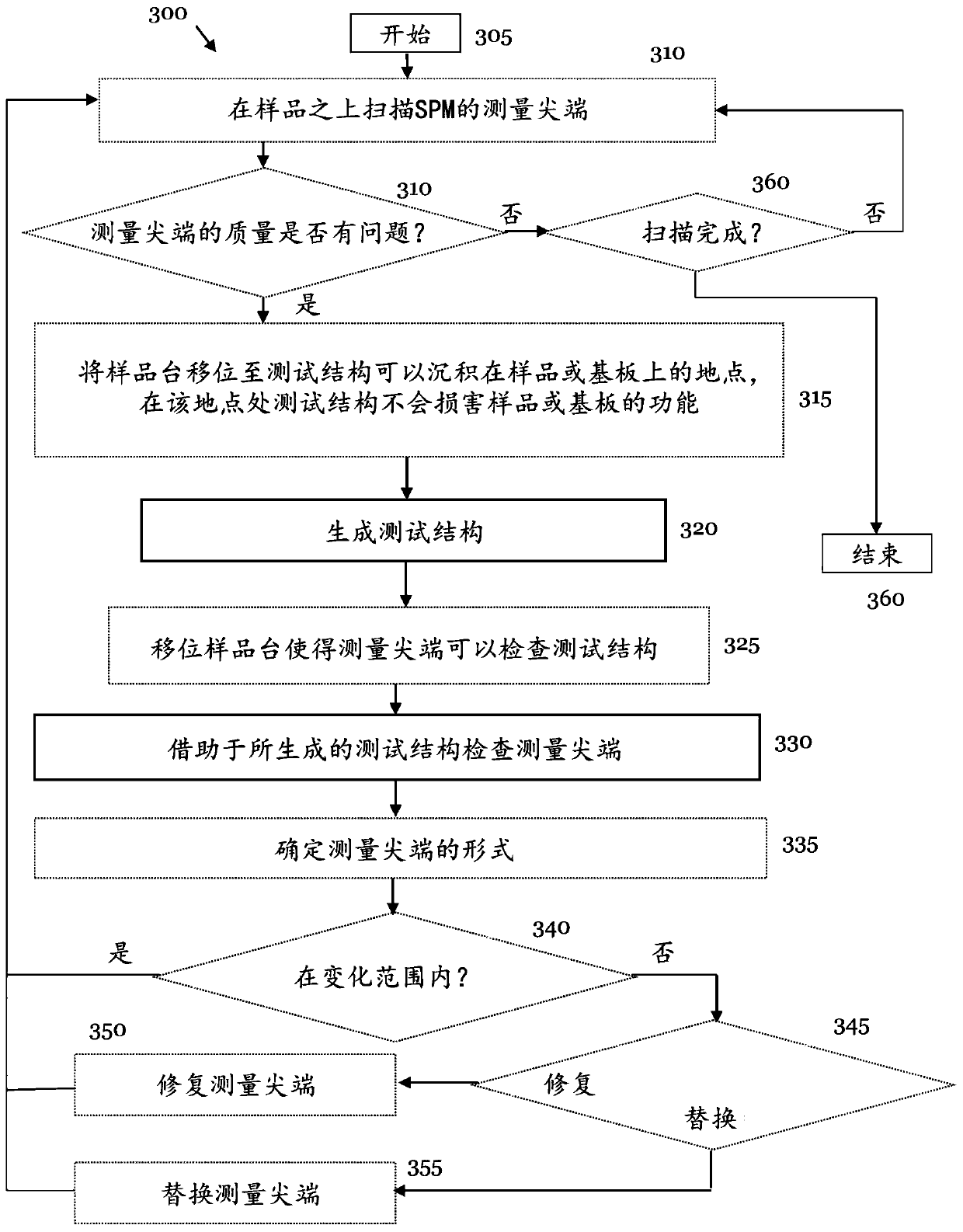

[0107] In the following, a presently preferred embodiment of a method for inspecting a measuring tip of a scanning probe microscope (SPM) according to the present invention is explained in more detail, taking an atomic force microscope (AFM) as an example. However, the method according to the invention is not limited to the application of atomic force microscopy. On the contrary, the method according to the invention can be used in all types of scanning probe microscopes, the measuring tip of which is subject to wear due to the interaction with the sample. Additionally, the defined method can be used to check for dirty measuring tips due to scanning the measuring tip over the sample surface.

[0108] In the following, the method according to the invention is explained using the example of analysis of a photolithography mask with a measuring tip of an AFM. However, the application of the method according to the invention is not limited to scanning on photolithographic masks. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com