A vibrating subsoiler

A subsoiler and subsoiling technology, applied in the field of soil subsoiling agricultural machinery and equipment, can solve the problem of subsoiling not well adapted to different soil properties, coaxial and coaxial axial force superimposition, and poor adaptability of soil breaker plow bottom and other problems, to achieve the effect of simple structure, disturbance improvement, and resonance avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

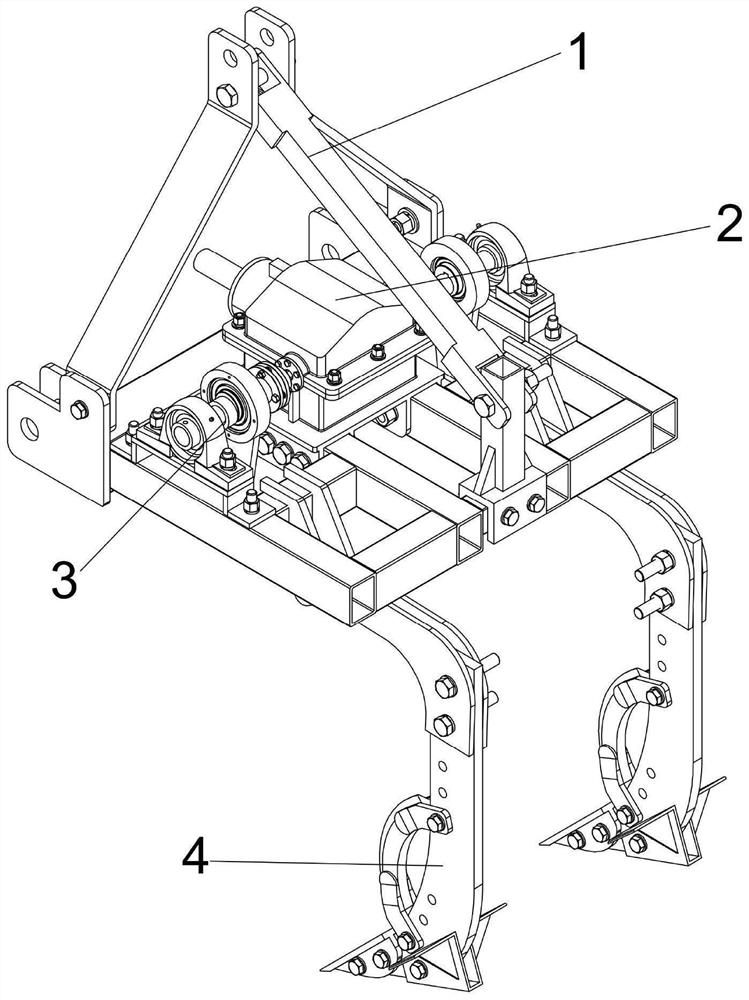

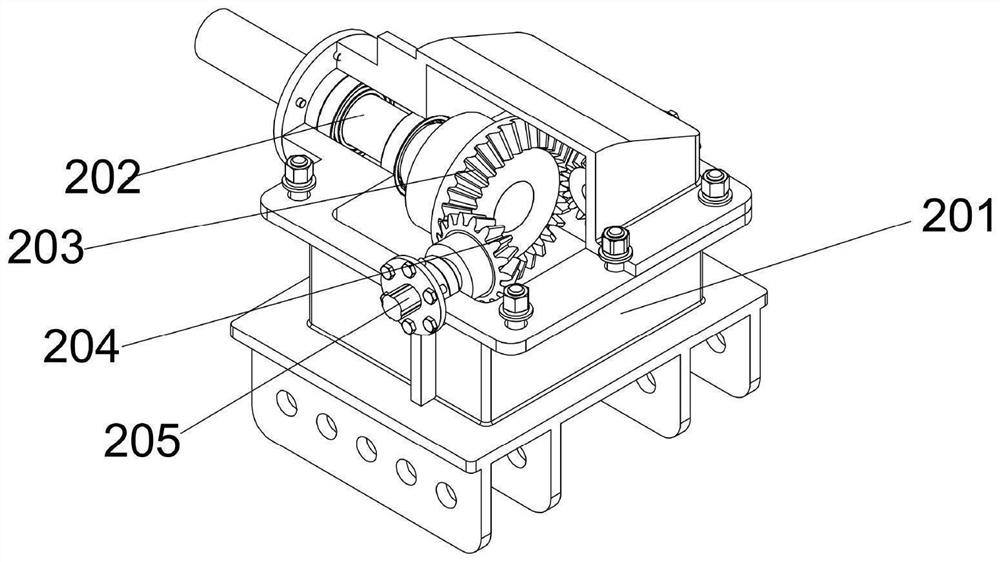

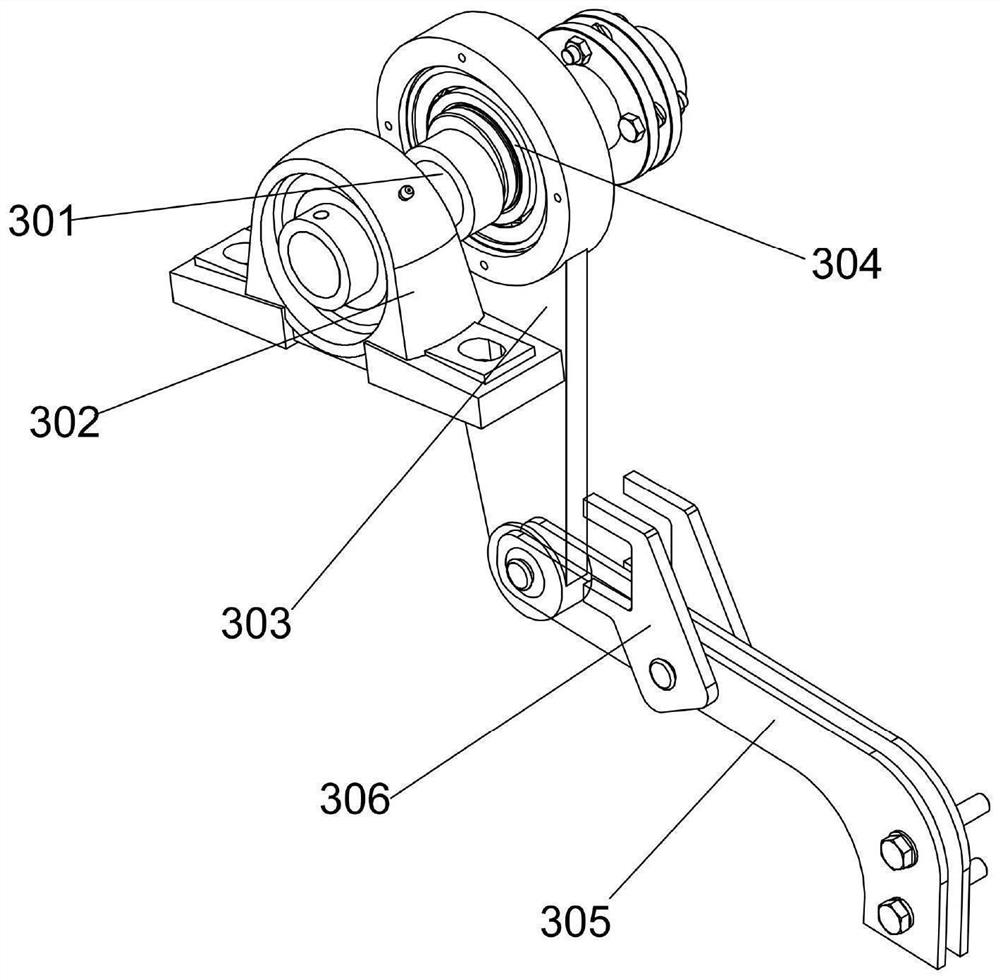

[0021] Such as Figure 1 to Figure 5 As shown, the vibration subsoiler described in this embodiment includes a subsoiler stand 1, a coaxial reverse transmission mechanism 2, a vibration swing transmission mechanism 3 and a subsoiler shovel 4 with a breaker 403; the subsoiler Stand 1 comprises underframe 102 and the three-point suspension device 101 that is contained on the underframe 102, and three suspension points 1011 of described three-point suspension device 101 are connected with the tractor (tractor) ahead, and described coaxial reverse The transmission mechanism 2 is installed on the underframe 102, and is connected with the power source of the front tractor. Two vibration and swing transmission mechanisms 3 are installed on the subsoiling platform 1, and the two vibration and swing transmission mechanisms 3 They are respectively arranged on both sides of the coaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com