Forging method for improving roll blank net shape level by using radial forging machine

A radial forging machine and mesh technology, which is applied in the forging field of using a radial forging machine to improve the mesh shape of roll blanks, can solve the problems of limited forging precision, high cost, and long production cycle, and achieve precise control and reduced tensile stress , The effect of improving the mesh pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

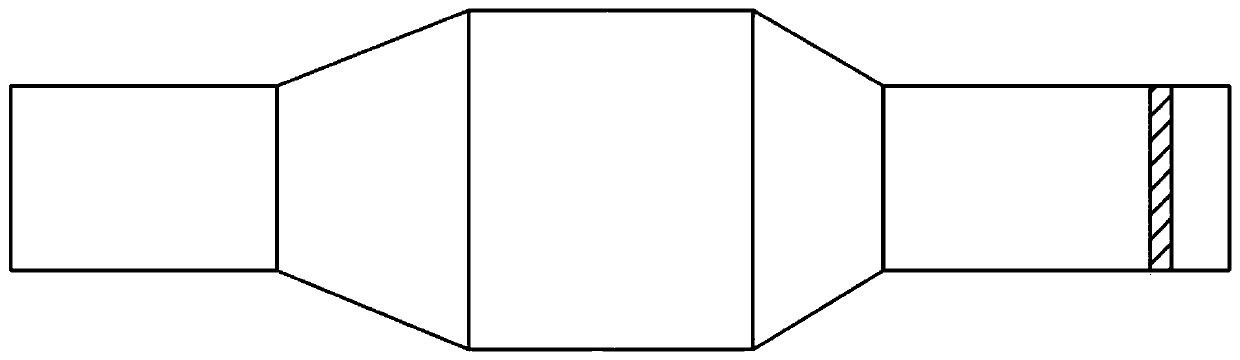

Image

Examples

Embodiment 1

[0023] The specific forging method steps are as follows:

[0024] Step 1. Heating with gas furnace, the heating temperature is 1190-1210°C, the holding time is 14-18h, and the furnace temperature is raised to 1210-1230°C 2-3h before upsetting;

[0025] Step 2. Use 30MN fast forging machine to upsetting and elongating;

[0026] Step 3. Transfer the upsetting and elongated billet to the forging area of the radial forging machine by using the transfer roller table, and control the surface temperature of the billet at 900°C to 920°C;

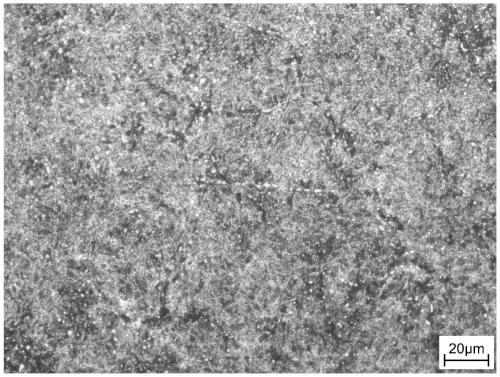

[0027] Step 4: forging with a 16MN radial forging machine, and heat-treating the forged billet to obtain a forged product. The forging frequency of the hammer head is 180 times / min. The roll body forging pass, the A-side roll neck forging pass, the B-side roll neck forging pass, and the finish forging pass are sequentially carried out by using a radial forging machine. Air cooling is performed before the finish forging pass. 30s to control the f...

Embodiment 2

[0037] The specific forging method steps are as follows:

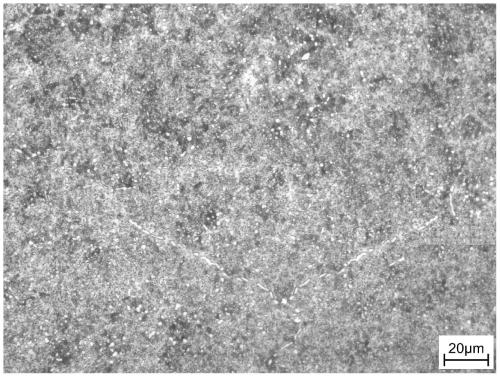

[0038] Steps 1 to 3 are the same as in Example 1, and Step 4 is forging with a 16MN diameter forging machine, and heat-treating the forged billet to obtain a forged product. The forging frequency of the hammer head is 180 times / min. The roll body forging pass, the A-side roll neck forging pass, the B-side roll neck forging pass, and the finish forging pass are sequentially carried out by using a radial forging machine. Air cooling is performed before the finish forging pass. 30s to control the forging temperature at the lower limit of the final forging temperature of 850±10°C, control the deformation of the finishing forging pass to 20mm according to the deformation rate of 87.3%, and forge the blank to the finished product. The specific forging steps are:

[0039] (1) Roll body forging passes: first pass: φ520mm→φ485mm, reduction 35mm, feed speed 3.5m / min, discharge speed 4.0m / min; second pass: φ485mm→φ480mm, reducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com