Method of treating workpiece surface, brush assembly, and rotatable brush tool

A technology for processing workpieces and components, applied in the direction of machine tools for surface polishing, devices for coating liquid on the surface, wheels of working parts with flexible effects, etc., which can solve the problem of manual implementation, non-direct implementation, and non-repeatable Processing workpieces and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

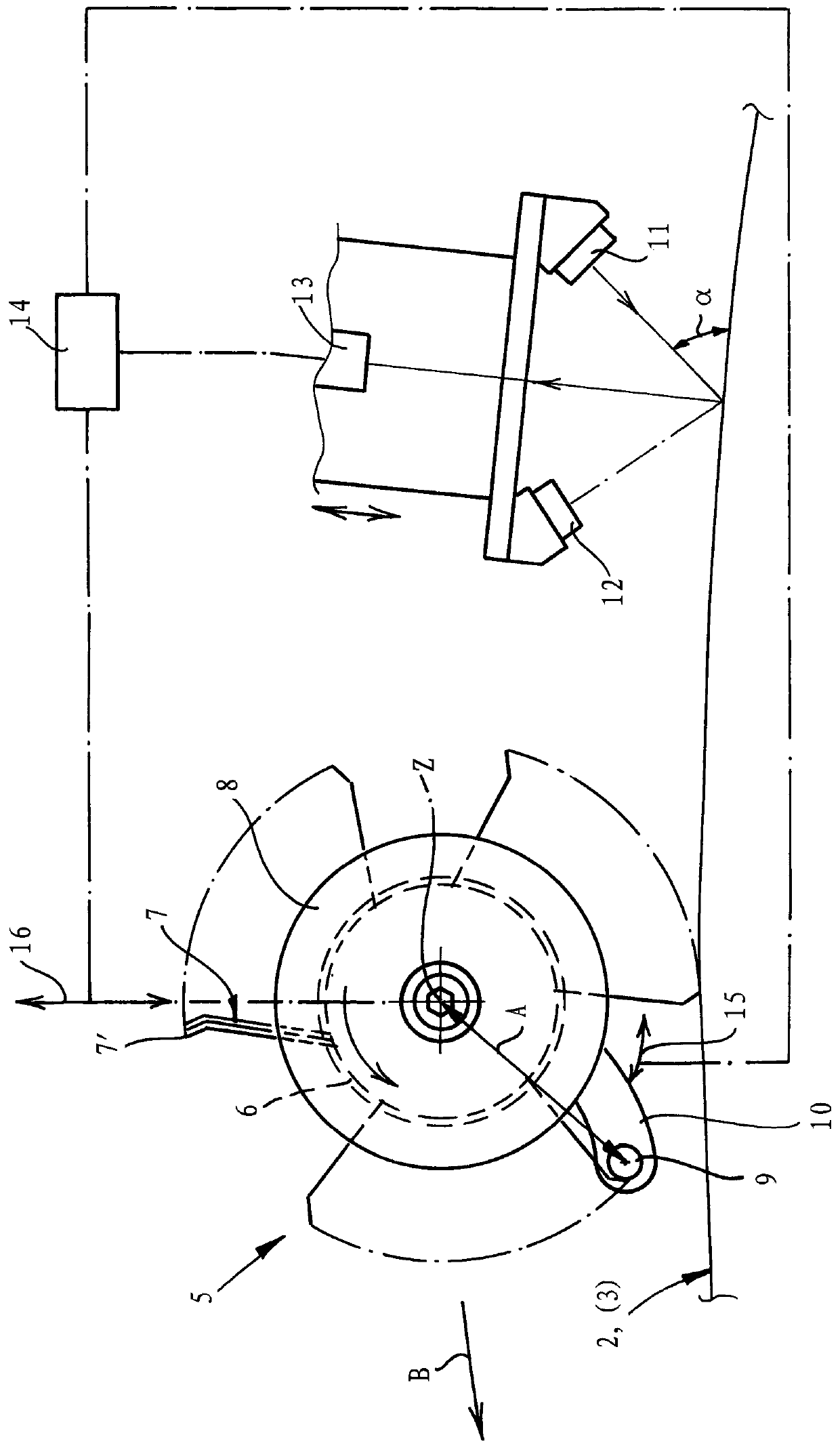

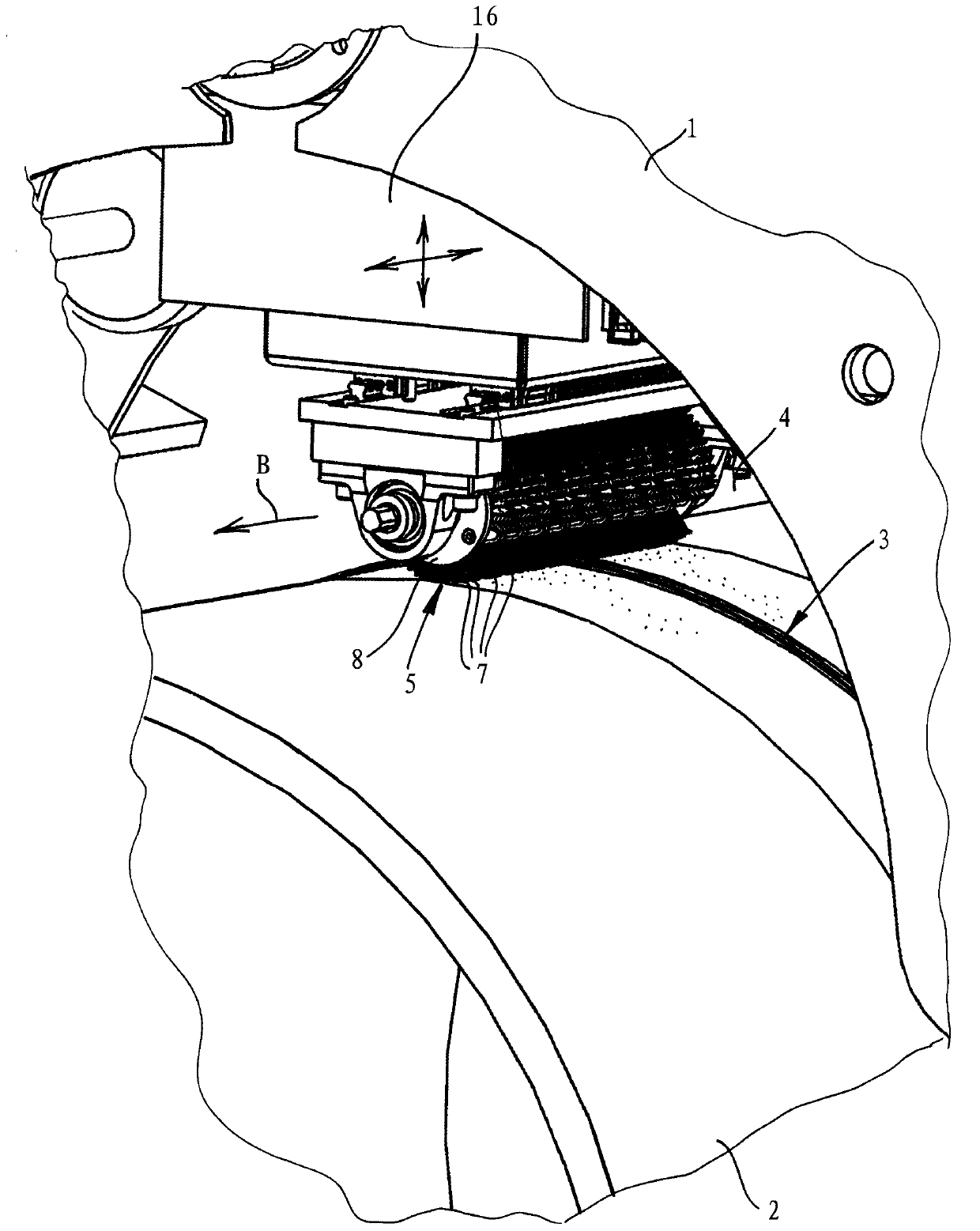

[0018] exist figure 1 A rotary brush tool, which is equipped with a machine frame 1 , is schematically shown in FIG. In this exemplary embodiment and without limitation, the machine frame 1 can form a cylindrical frame section which is adapted to the workpiece 2 to be processed. According to this embodiment and without limitation, the workpiece 2 is a pipeline or pipeline line consisting of a plurality of individual mutually welded tubes. Here, each tube passes through the figure 1The weld seam 3 can be seen in the interconnection. In order to protect the weld seam 3 and generally the connection area of the tubes to one another from corrosion, in the exemplary case the surface of the workpiece 2 in the area of the weld seam 3 is machined by means of a rotating brush tool which will be described in more detail below. Following the machining, a protective coating can be applied to the line or workpiece 2 in this region.

[0019] In principle, the rotating brush tool desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com