Longitudinal beam type transfer vehicle structure

A technology of vehicles and longitudinal beams, applied to the arrangement of loading and unloading vehicles, vehicles with cranes, vehicles used for freight, etc., can solve problems such as inconvenient operation, inconvenient lifting and towing operations, secondary collisions, etc., and achieve lifting and traction Convenient operation, stable and reliable transportation process, and the effect of reducing secondary collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

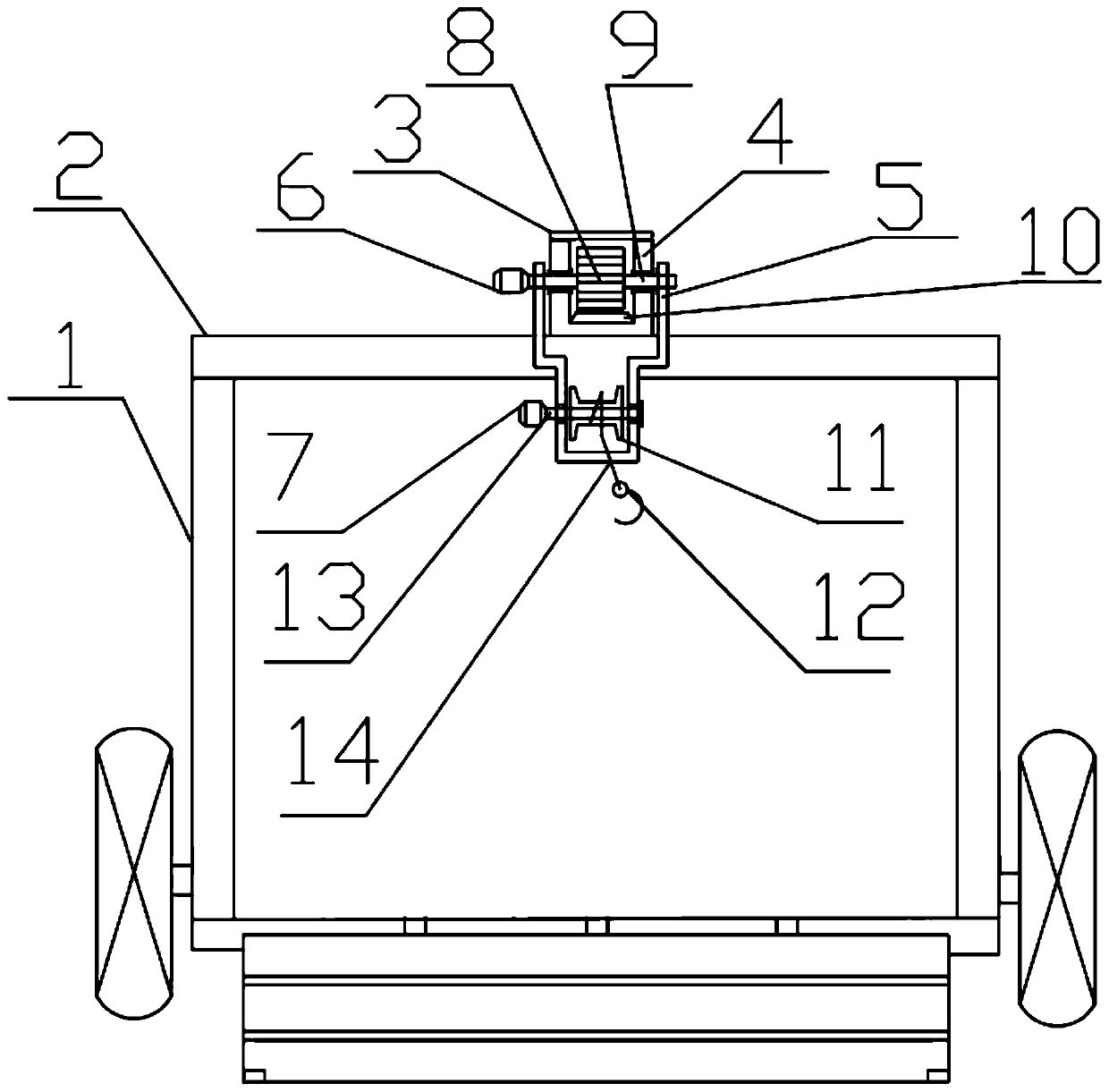

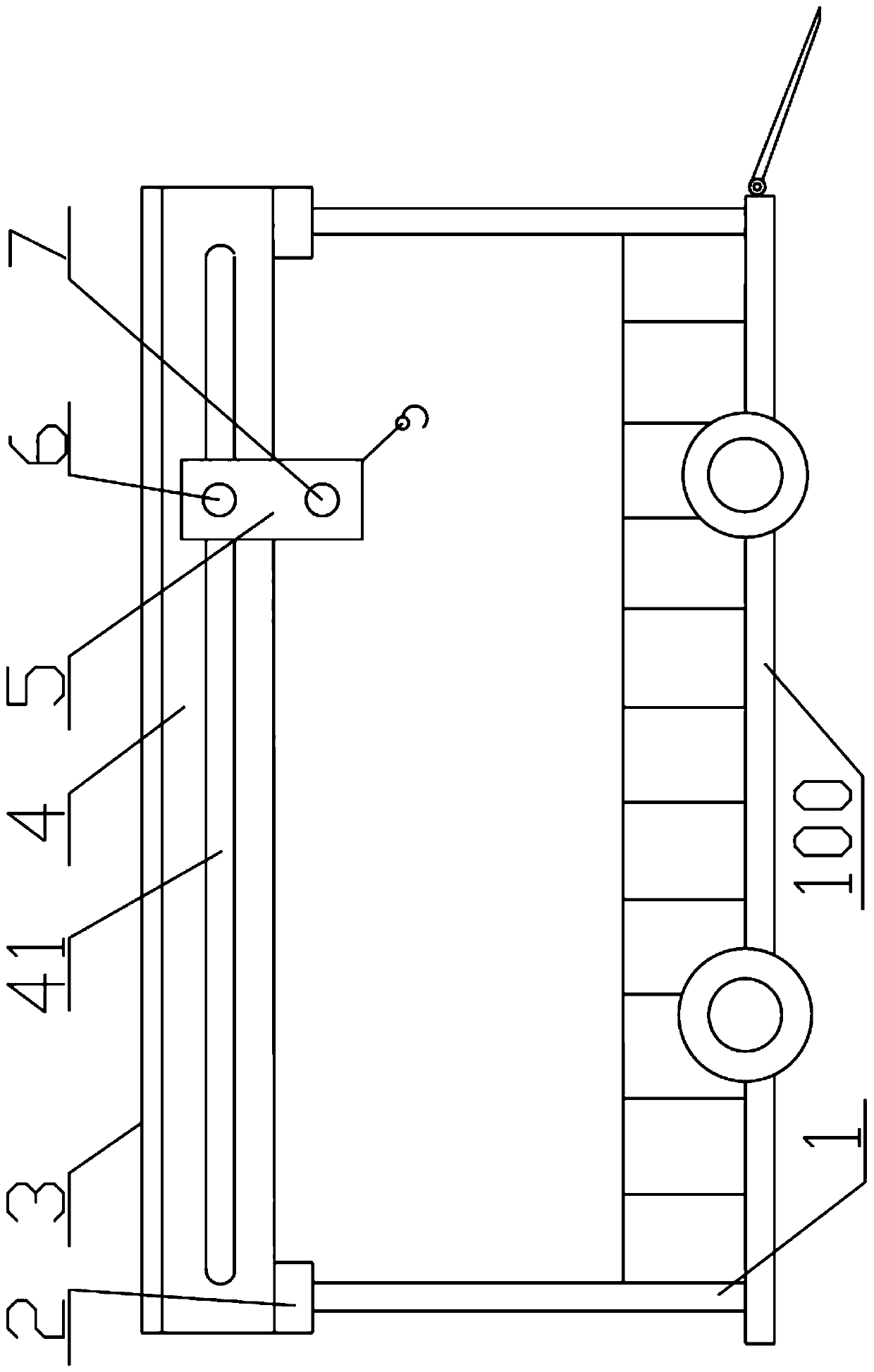

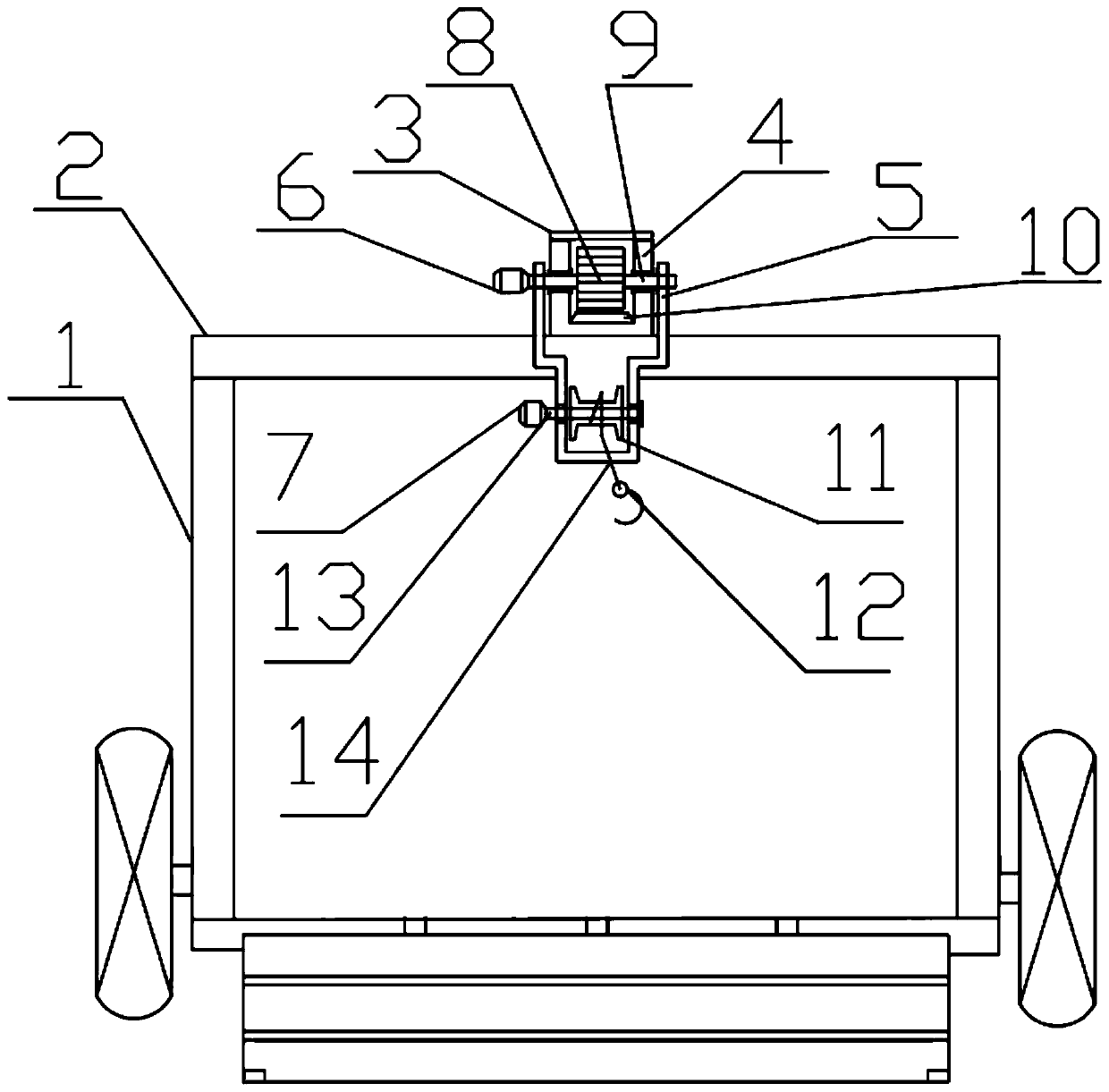

[0028] Instructions

[0029] When using a special trailer, use the remote control device to put down the hook, and then hang the hook on the wire rope of the front wheel of the accident car. The remote control device will lift the hook and the front of the accident car. The drive wheel rotates on the rack to drive the front of the accident car to move from the front of the trailer box at the rear of the trailer, and the rear wheel of the accident car enters the trailer box through the transition plate of the trailer, and the over-close sheet. When unloading the accident car, the operation process can be reversed.

[0030] The advantage is:

[0031] Columns, beams and longitudinal beams together form a frame structure instead of the trailer box, which simplifies the structural design.

[0032] The structural design is optimized, which is beneficial to manufacturing and reduces manufacturing cost.

[0033] The guardrails on both sides of the car enhance the fixation of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com