Belt conveyor control device and method based on multi-target particle swarm algorithm

A multi-objective particle swarm and belt conveyor technology, which is applied in the field of sensing and measurement and control, can solve problems such as the inability to predict the optimal transportation volume, and achieve the effects of saving manpower and material resources, prolonging service life, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

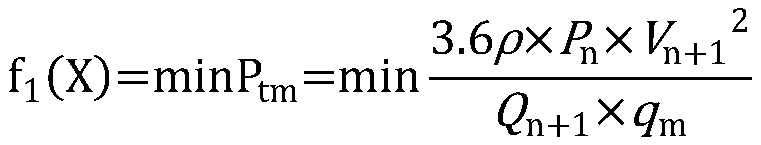

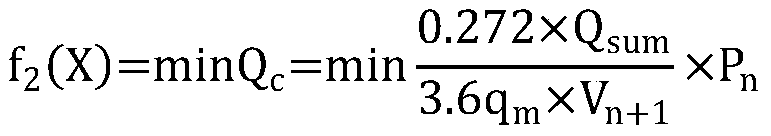

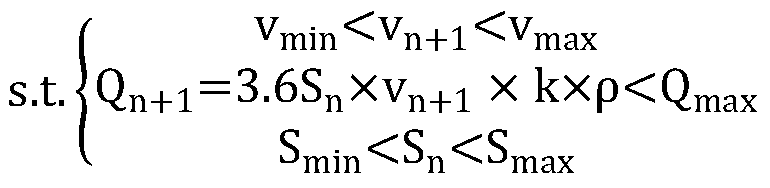

Method used

Image

Examples

Embodiment Construction

[0053] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0054] A belt conveyor control system based on a multi-objective particle swarm algorithm, comprising: a material flow laser acquisition device, a photoelectric encoder, a signal acquisition and processing module, a conveyor coordination control device, and a conveyor execution module.

[0055] The material flow laser acquisition device is used to monitor the instantaneous cross-sectional area of the material on the conveyor belt. Among them, the material flow laser acquisition device is installed vertically above the conveyor belt, aligned vertically downward to the material flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com