Arc method for measuring orifice size of molten bath for plasma welding and signal acquisition system

A plasma welding and plasma arc technology, applied in the field of plasma welding quality control, can solve problems such as poor sensor accessibility, and achieve the effects of good accessibility and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

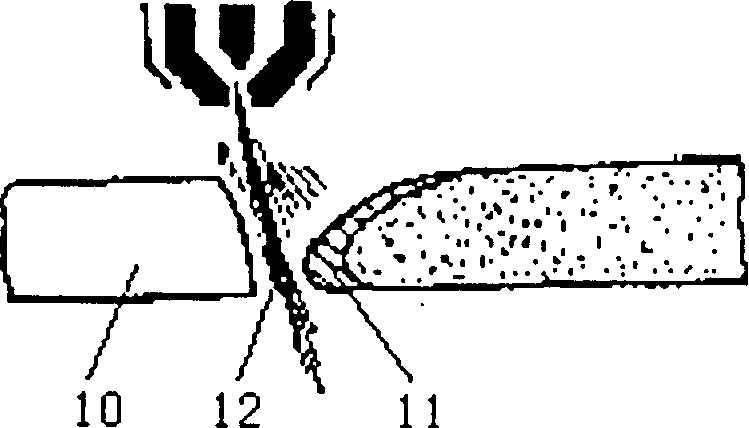

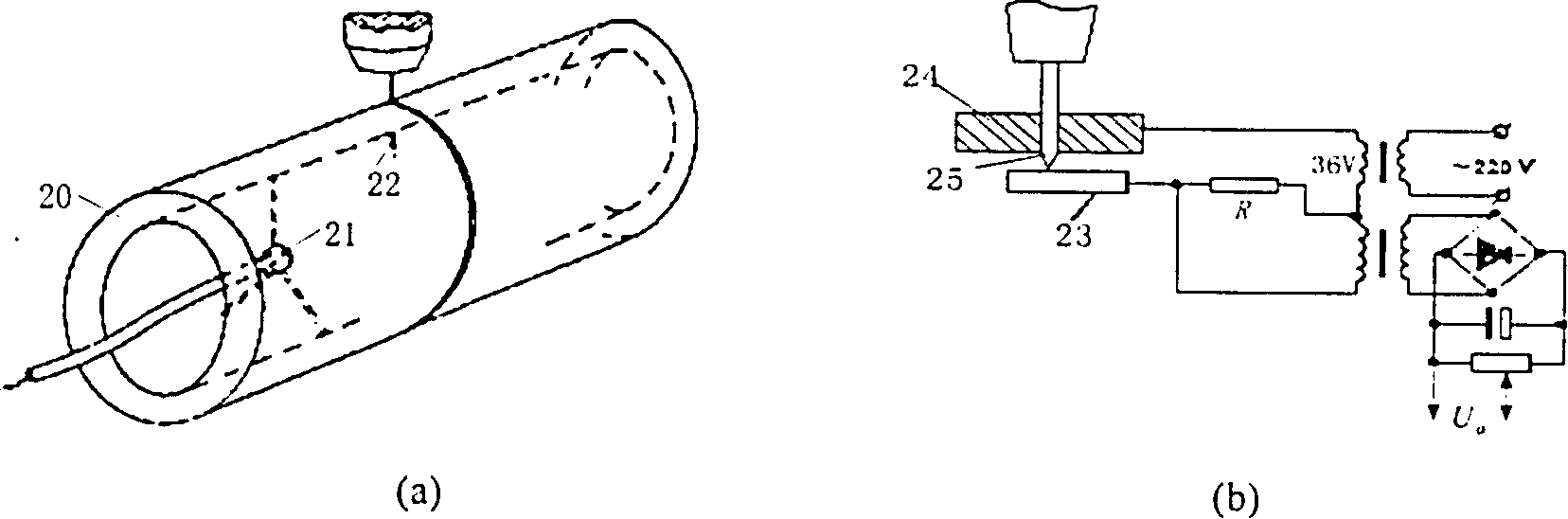

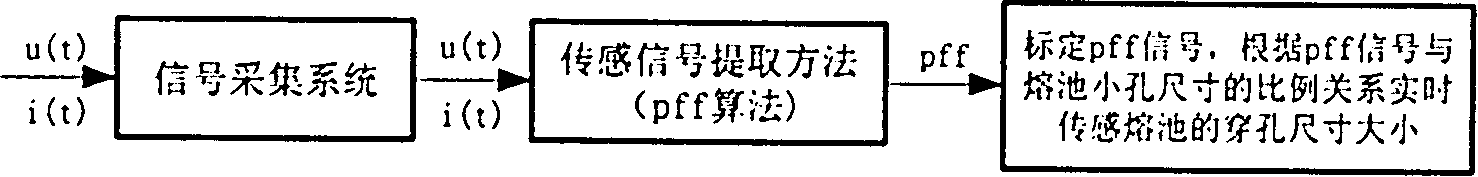

[0031] A kind of arc detection method and signal acquisition system embodiment of the small hole size of the plasma welding pool designed by the present invention are described in detail as follows in conjunction with the accompanying drawings:

[0032] Considering changes in heat dissipation conditions, workpiece thickness, and welding specifications in actual production, the workpiece with a gradual thickness change is used. The thickest part of the workpiece is 8mm, and the thinnest part is 3mm. The welding specification is set so that the thickness of the workpiece is 6mm. , welded on stainless steel workpieces using an inverter welder. The shape of workpiece with gradient thickness and its corresponding weld backside are as follows: Figure 8 a and Figure 8 As shown in b, it can be seen that the weld seam on the back side grows from nothing and gradually becomes thicker. Obviously, the molten pool has experienced a process from never perforated to perforated from small ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com