High-entropy alloy of double-layer close-packed hexagonal structure

A technology of close-packed hexagonal and high-entropy alloys is applied in the field of double-layer close-packed hexagonal structure high-entropy alloys to achieve the effect of promoting application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

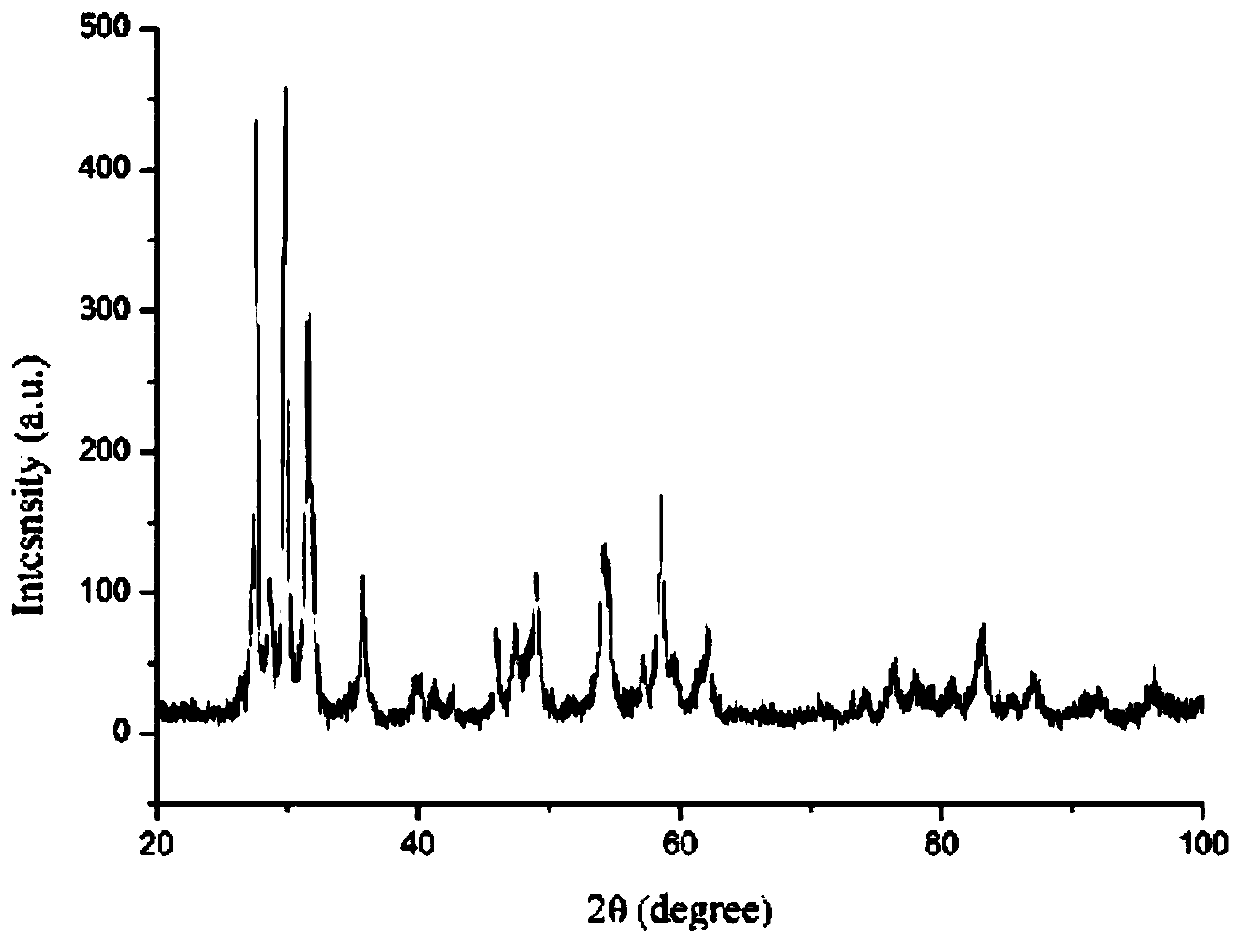

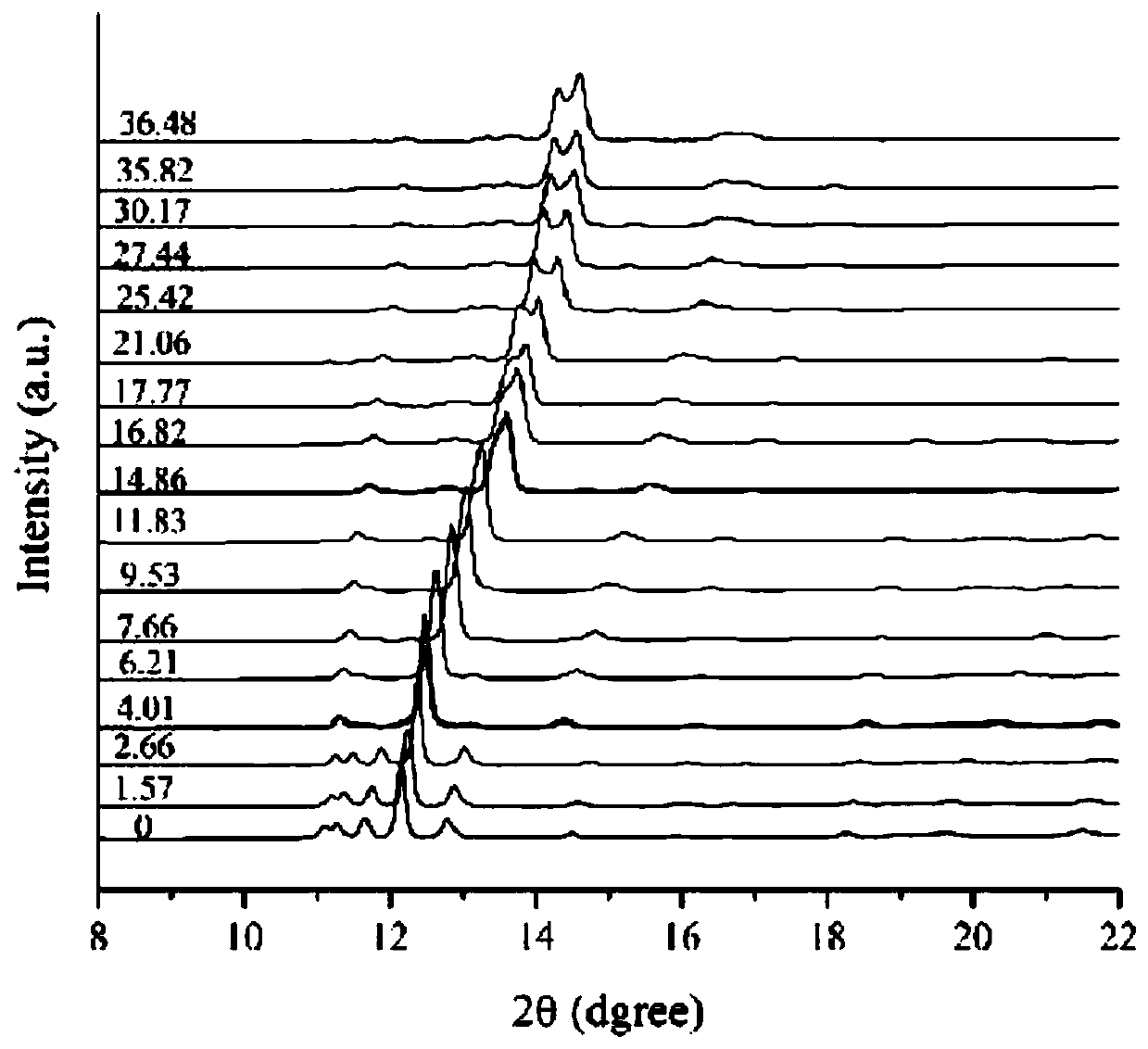

[0032] Embodiment one (as figure 1 , image 3 )

[0033] A high-entropy alloy with double-layer close-packed hexagonal structure, whose composition is La x Ce x PR x Nd x , where x is the atomic percentage x=25. La x Ce x PR x Nd x The alloy has two structures of face-centered cubic (fcc) and twisted face-centered cubic (dfcc) under high pressure.

[0034] High entropy alloy La with double-layer close-packed hexagonal structure 25 Ce 25 PR 25 Nd 25 The preparation method is as follows:

[0035] (1) Weigh La: 25%, Ce: 25%, Pr: 25%, Nd: 25% as raw materials according to equal atomic percentage, and the purity of the above light rare earth metals is in the range of 99.5wt%-99.9wt%;

[0036] (2) Mix the above raw material components evenly and put them into a high vacuum arc melting furnace for melting, and carry out melting under the protective atmosphere of high-purity argon gas. During the melting process, the alloy ingot is repeatedly turned over 4 to 5 times to...

Embodiment 2

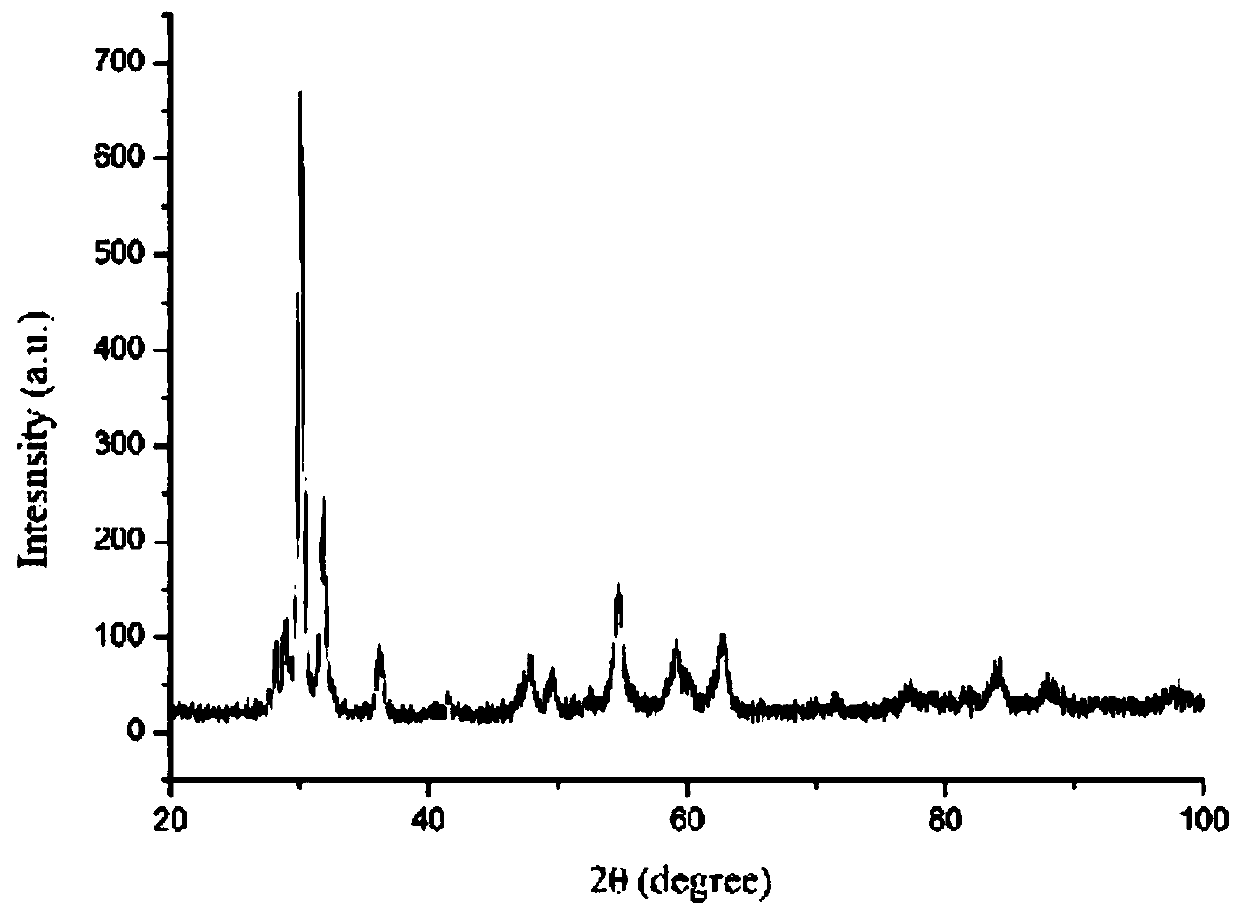

[0041] Embodiment two (as figure 2 , Figure 4 )

[0042] A high-entropy alloy with double-layer close-packed hexagonal structure, whose composition is La x Ce x PR x Nd x SM x , where x is the atomic percentage x=20. High entropy alloy La with double-layer close-packed hexagonal structure 20 Ce 20 PR 20 Nd 20 SM 20 , under high pressure, have two structures of face-centered cubic (fcc) and twisted face-centered cubic (dfcc).

[0043] High entropy alloy La with double-layer close-packed hexagonal structure 20 Ce 20 PR 20 Nd 20 SM 20 The preparation method is as follows:

[0044] (1) Weigh La: 20%, Ce: 20%, Pr: 20%, Nd: 20%, Sm: 20% with a purity of 99.5wt%-99.9wt% according to the equal atomic percentage as raw materials;

[0045] (2) The above-mentioned raw material components are mixed evenly and put into a high-vacuum electric arc melting furnace for smelting, smelting is carried out for 4 to 5 times under a protective atmosphere of high-purity argon, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com