Piezoelectric sensor and preparation method thereof

A piezoelectric sensor, piezoelectric technology, applied in piezoelectric devices/electrostrictive devices, fluid pressure measurement using piezoelectric devices, and measurement of property forces using piezoelectric devices, which can solve the problem of affecting the manufacturing cost of sensors. , It is difficult to further improve the performance of the sensor sensitivity and signal-to-noise ratio, etc., to achieve the effect of improving sensitivity and signal-to-noise ratio, strong compatibility, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

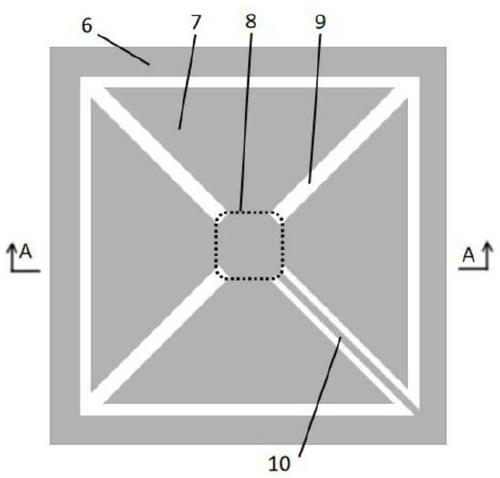

[0060] refer to figure 1 , in this embodiment, the piezoelectric sensor includes four inverted trapezoidal piezoelectric diaphragms 7; the fixed end is located in the fixed area 8 in the center of the substrate; The gap 9 can reduce the air damping when the piezoelectric diaphragm 7 vibrates, and reduce the noise signal of the sensor; between the gaps 9, a connection structure 10 connecting the outer periphery 6 of the substrate and the fixed area 8 is provided, for use Subsequently, the electric signal generated by the piezoelectric diaphragm 7 due to the piezoelectric effect is drawn out on the periphery 6 of the substrate.

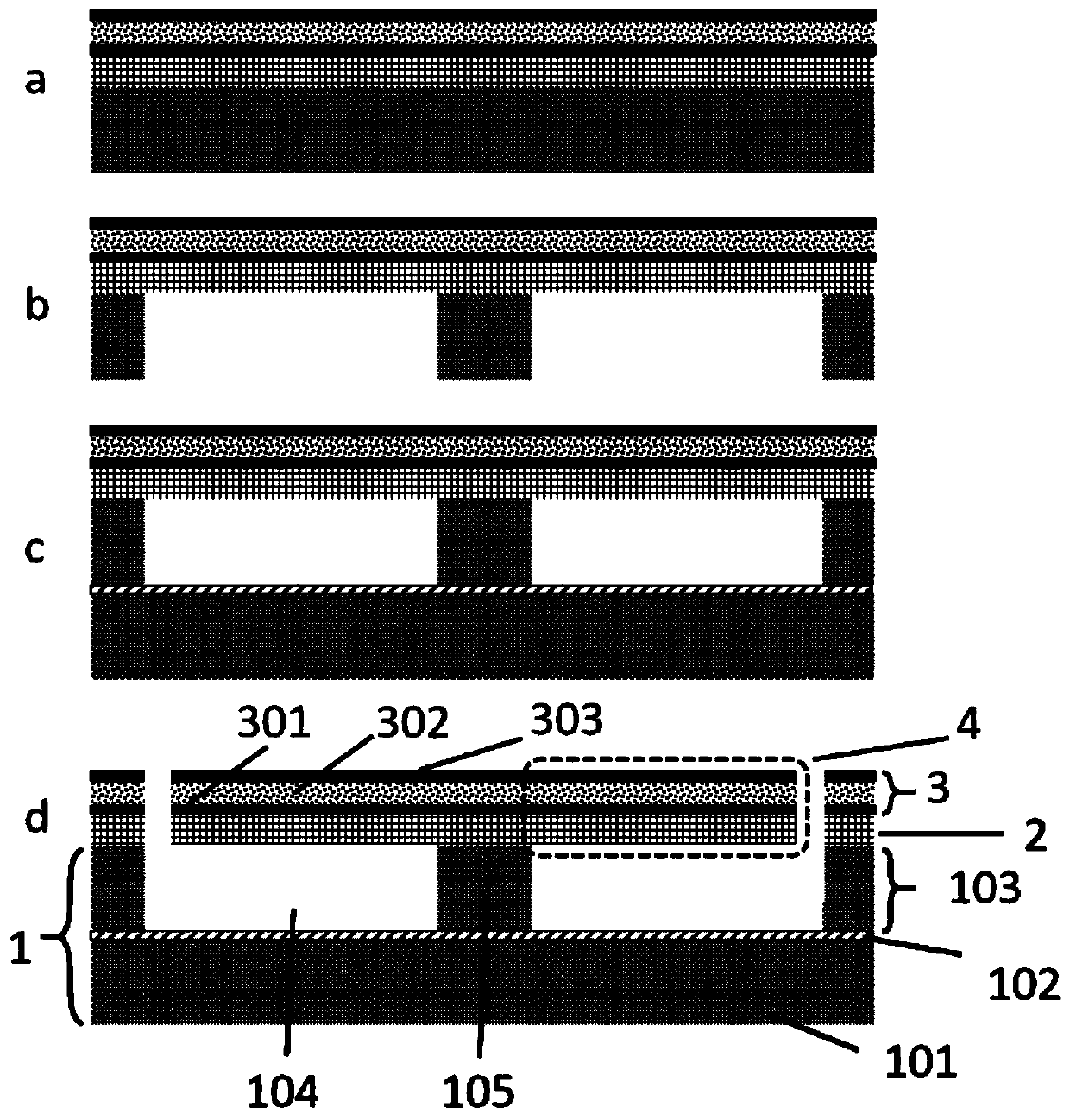

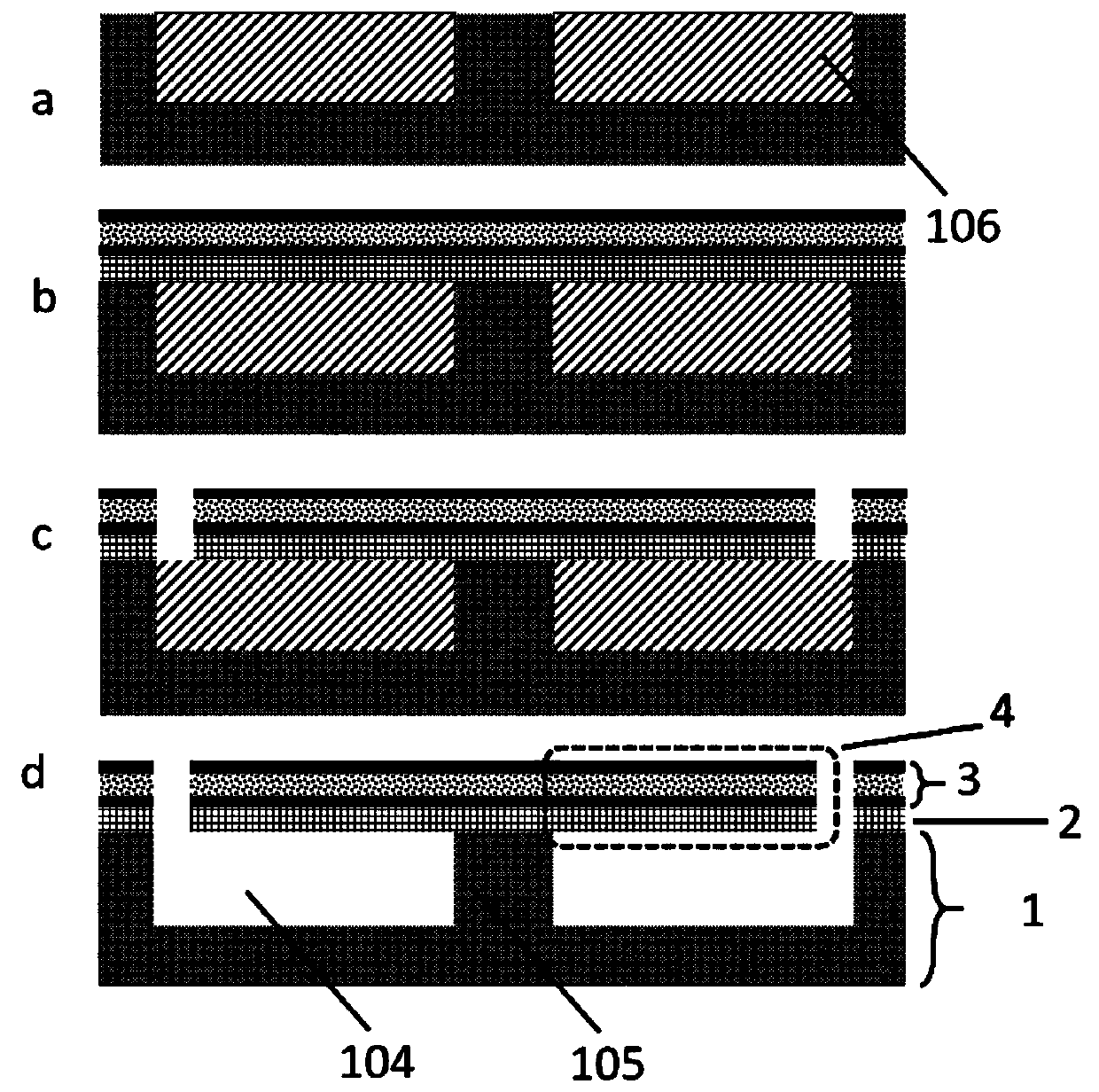

[0061] refer to figure 2 , in one embodiment, propose the first kind of preparation method of piezoelectric sensor, comprise the following steps:

[0062] Step 1: Depositing the device supporting layer 2 and the piezoelectric stack 3 on the substrate 1, wherein the material of the substrate fixing layer 101 in the substrate 1 is Si, the material of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com