Single-layer glass metal grid capacitive touch cover plate and preparation method thereof

A metal grid, capacitive touch technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problems of increased manufacturing cost, complex process, poor stability, etc., to achieve low manufacturing cost, process Simple and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

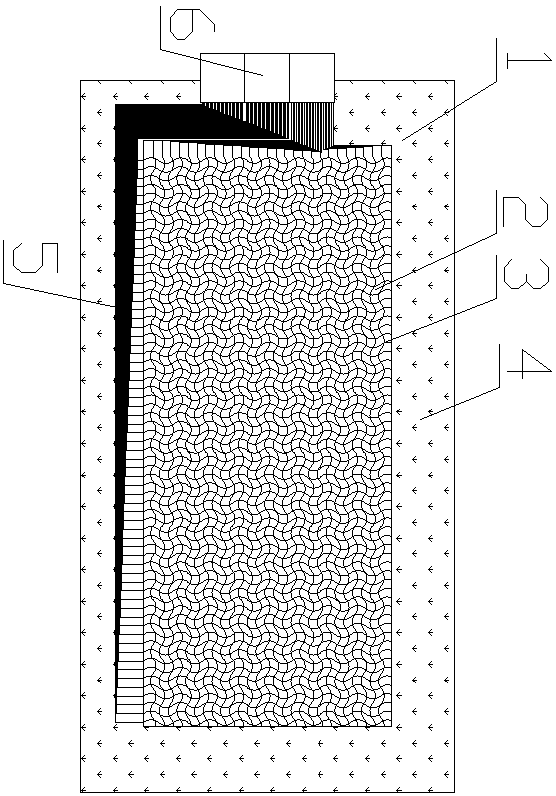

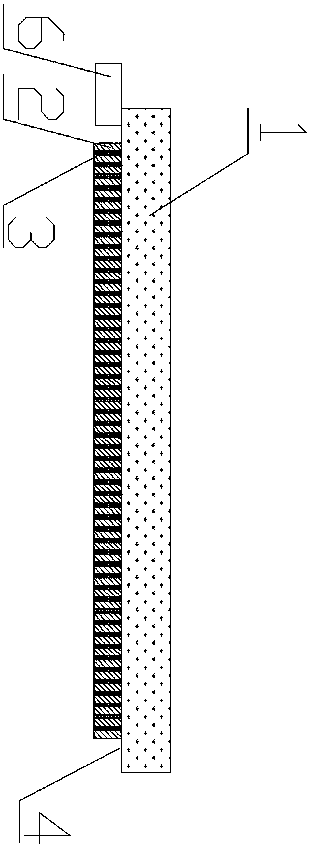

[0035] Such as figure 1 , figure 2 As shown, a single-layer glass metal mesh capacitive touch cover plate includes a transparent glass 1, a solidified layer 2 is provided on one surface of the transparent glass 1, and the cured layer 2 is provided on the non-screen surface and also on the non-screen printing surface. On the screen printing surface 4, the cured layer 2 on the screen printing surface 4 is mainly used to fix the metal grid lines 3 drawn from the non-screen printing area that is arranged with the wiring structure 5 and whose end is connected to the soldering point of the FPC flexible cable 6; The layer 2 is inlaid with metal grid lines 3 which are distributed in cross-contact and close to the surface of the transparent glass 1, and the edge of the transparent glass 1 is provided with a silk screen surface 4 formed by silk printing.

[0036] Described metal grid line 3 comprises horizontal metal grid line and longitudinal metal grid line, lays insulating enameled...

Embodiment 2

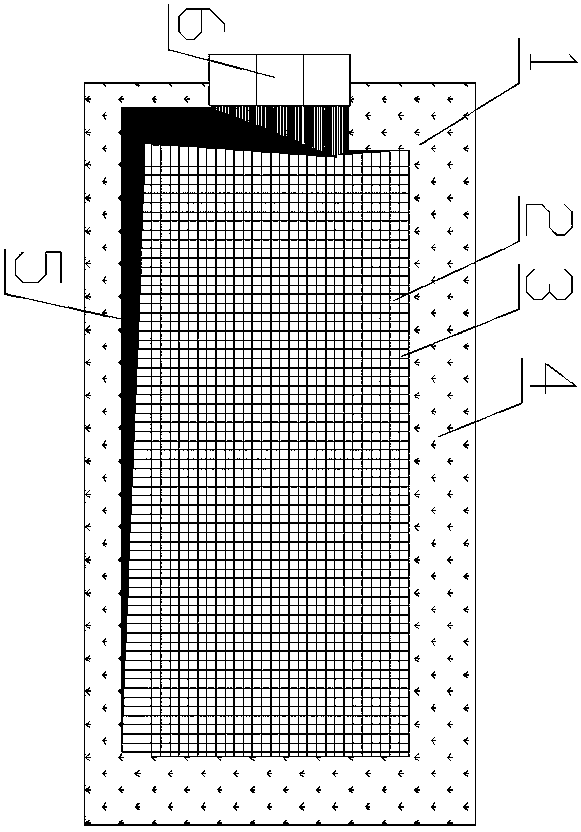

[0041] Embodiment 2: as image 3 As shown, the difference from Embodiment 1 is that the metal grid lines 3 are arranged in a square shape.

Embodiment 3

[0042] Embodiment 3: as Figure 4 As shown, the difference from Embodiment 1 is that the metal grid lines 3 are arranged in a rhombus shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com