A kind of anti-overcharge safe electrolyte for lithium battery

An anti-overcharge and electrolyte technology, applied in secondary batteries, organic electrolytes, non-aqueous electrolytes, etc., to reduce negative effects, improve cycle performance, and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

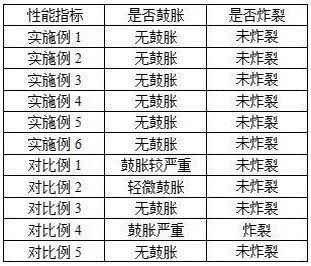

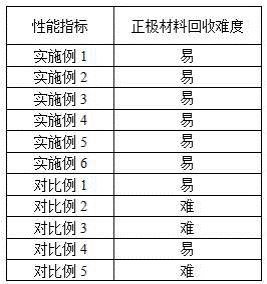

Examples

Embodiment 1

[0028] An anti-overcharge safe electrolyte for lithium batteries, the safe electrolyte is composed of organic solvents, electrolytes, film-forming additives, flame retardant additives, and composite anti-overcharge additives in a mass ratio of 100:18:4:1:2 composition.

[0029]The preparation method of the composite anti-overcharge additive is to mix 2,7-dibromo-9-fluorenone and N-(2,4,6-trichlorophenyl)maleimide evenly in a mass ratio of 2.5:1, and heat To complete melting to obtain a mixed melt, then add porous nano-silica to the excess mixed melt, ultrasonically oscillate for 24 hours, then suction filter, cool, and grind to particles with a particle size of 50-100nm;

[0030] The organic solvent is a mixed solvent of ethylene carbonate / dimethyl carbonate (the volume ratio of ethylene carbonate to dimethyl carbonate is 1:1);

[0031] The electrolyte is lithium hexafluorophosphate;

[0032] The film-forming additive is composed of vinyl sulfite and N-methylpyrrole in a mas...

Embodiment 2

[0035] An anti-overcharge safe electrolyte for lithium batteries, the safe electrolyte is composed of organic solvents, electrolytes, film-forming additives, flame retardant additives, and composite anti-overcharge additives in a mass ratio of 100:17:5:3:2.5 composition.

[0036] The preparation method of the composite anti-overcharge additive is to mix 2,7-dibromo-9-fluorenone and N-(2,4,6-trichlorophenyl)maleimide evenly in a mass ratio of 2.8:1, and heat To complete melting to obtain a mixed melt, then add porous nano-silica to the excess mixed melt, ultrasonically oscillate for 24 hours, then suction filter, cool, and grind to particles with a particle size of 50-100nm;

[0037] The organic solvent is a mixed solvent of ethylene carbonate / ethyl methyl carbonate (the volume ratio of ethylene carbonate to ethyl methyl carbonate is 1:1);

[0038] The electrolyte is lithium hexafluorophosphate;

[0039] The film-forming additive is composed of vinyl sulfite and N-methylpyrro...

Embodiment 3

[0042] An anti-overcharge safe electrolyte for lithium batteries, the safe electrolyte is composed of organic solvents, electrolytes, film-forming additives, flame retardant additives, and composite anti-overcharge additives in a mass ratio of 100:17:4:2:3 composition.

[0043] The preparation method of the composite anti-overcharge additive is to mix 2,7-dibromo-9-fluorenone and N-(2,4,6-trichlorophenyl)maleimide evenly in a mass ratio of 2.2:1, and heat To complete melting to obtain a mixed melt, then add porous nano-silica to the excess mixed melt, ultrasonically oscillate for 12 hours, then suction filter, cool, and grind to particles with a particle size of 50-100nm;

[0044] The organic solvent is a mixed solvent of ethylene carbonate / diethyl carbonate (the volume ratio of ethylene carbonate and diethyl carbonate is 1:1);

[0045] The electrolyte is lithium hexafluorophosphate;

[0046] The film-forming additive is composed of vinyl sulfite and N-methylpyrrole in a mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com