Pipeline burst prevention valve assembly

A pipeline and valve technology, applied in the field of immunological reaction devices, can solve the problems of death, toxic and harmful substances leakage environment, bursting of transportation pipelines, etc., and achieve the effect of ensuring the safety of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

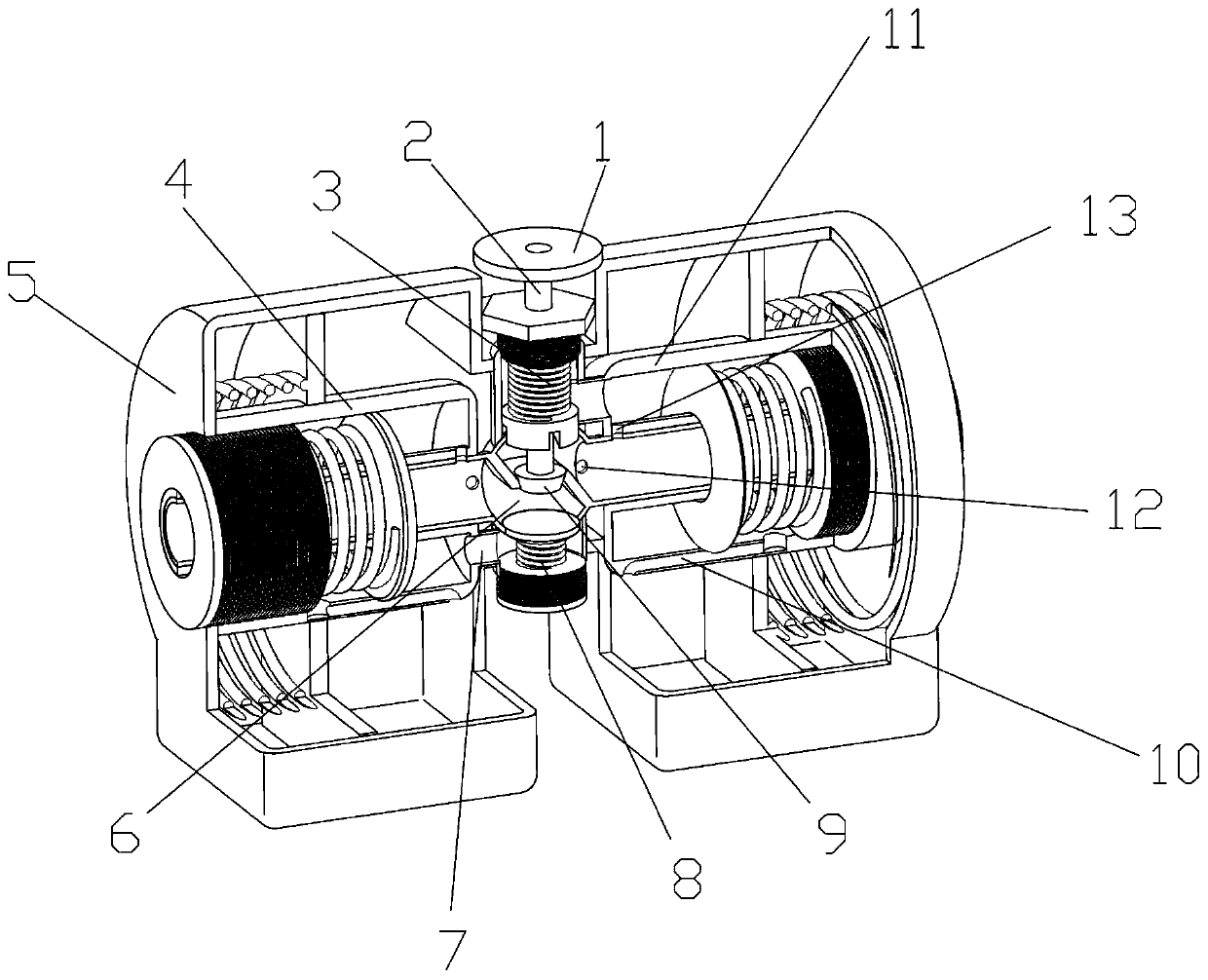

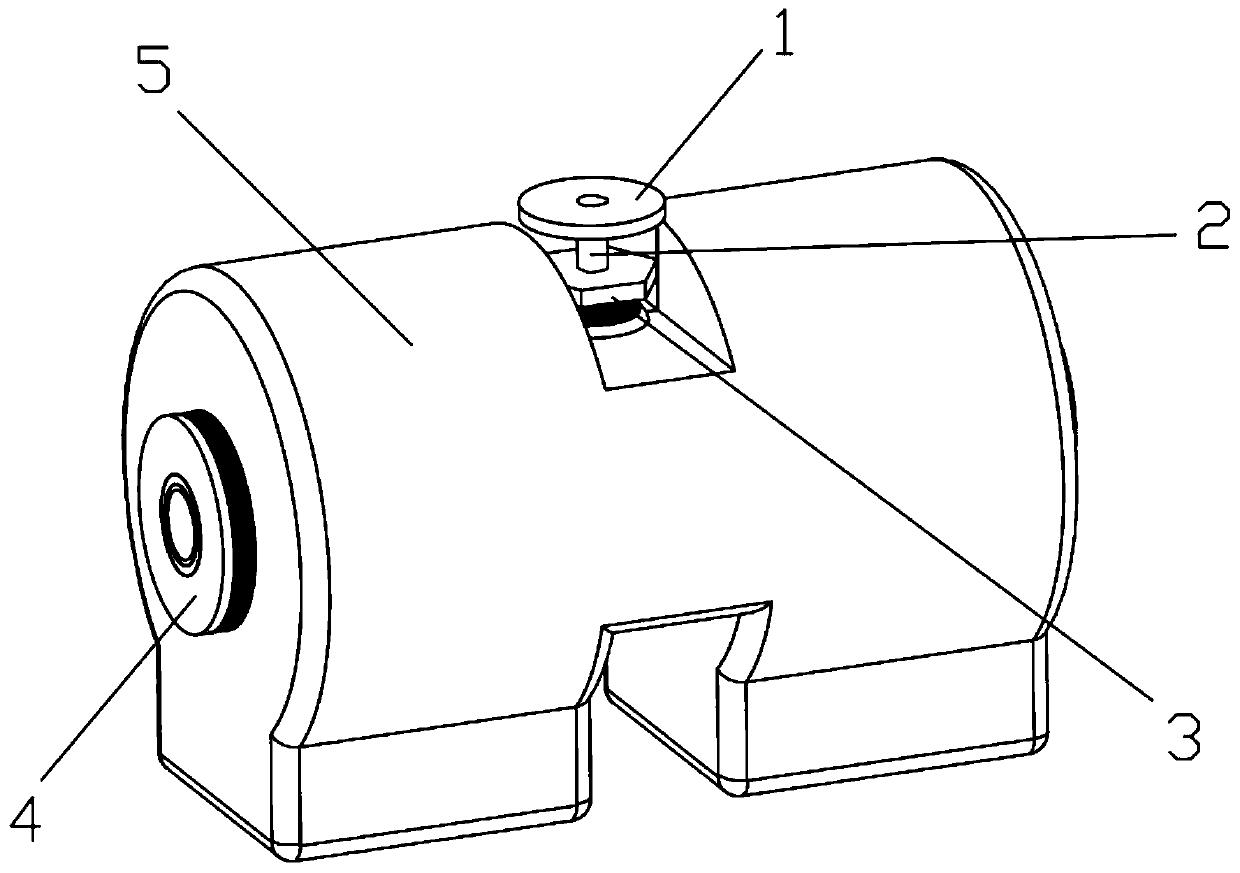

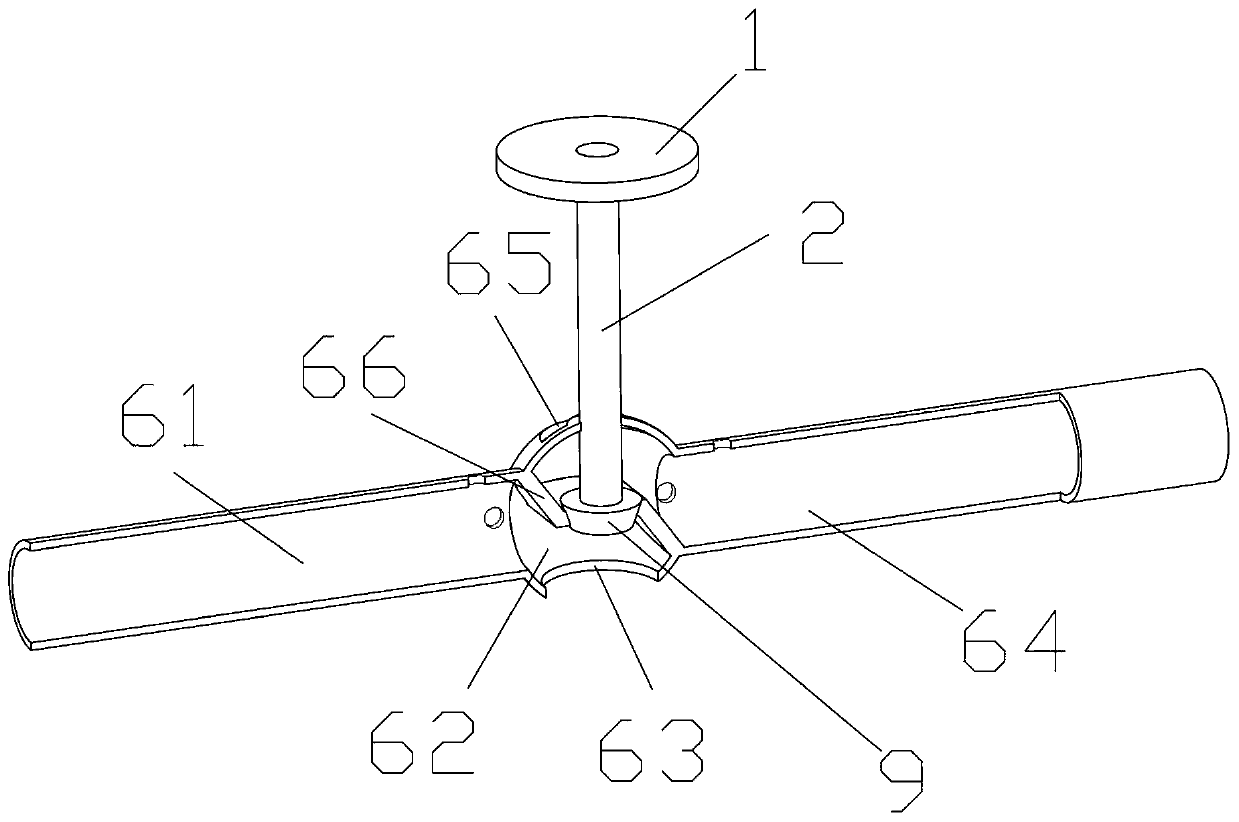

[0036] see Figure 1-8 As shown, a pipeline burst prevention valve includes a rotating disc 1, a valve shaft 2, an upper pressure response structure 3, an input pipeline pressure buffer chamber 4, a secondary pressure buffer chamber 5, a basic valve body 6, a connecting pipe 7, a lower pressure Reaction structure 8, spool 9, Unicom cavity 10, output pipe pressure buffer chamber 11, secondary pressure buffer chamber return pipe 12 and pipeline pressure buffer chamber return pipe 13, the spool 9 is set inside the basic valve body 6, the spool 9 The upper end is fixedly connected with the lower end of the valve shaft 2, the upper end of the valve shaft 2 penetrates the upper side of the basic valve body 6, and the valve shaft 2 is threadedly connected with the upper end of the basic valve body 6, the upper end of the valve shaft 2 is fixedly connected with the rotating disc 1, and the input pipe The pressure buffer chamber 4 is set on one side of the basic valve body 6, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com