High-concentration tailing filling slurry stirring process optimization method

A technology of stirring process and filling slurry, which is applied in design optimization/simulation, image data processing, 3D modeling, etc., can solve the difficult quantitative optimization of stirring device and process parameters, and the distribution law of time and space that cannot be quantified and other issues to achieve the effect of shortening the test and debugging cycle, reducing processing costs, and reducing the risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

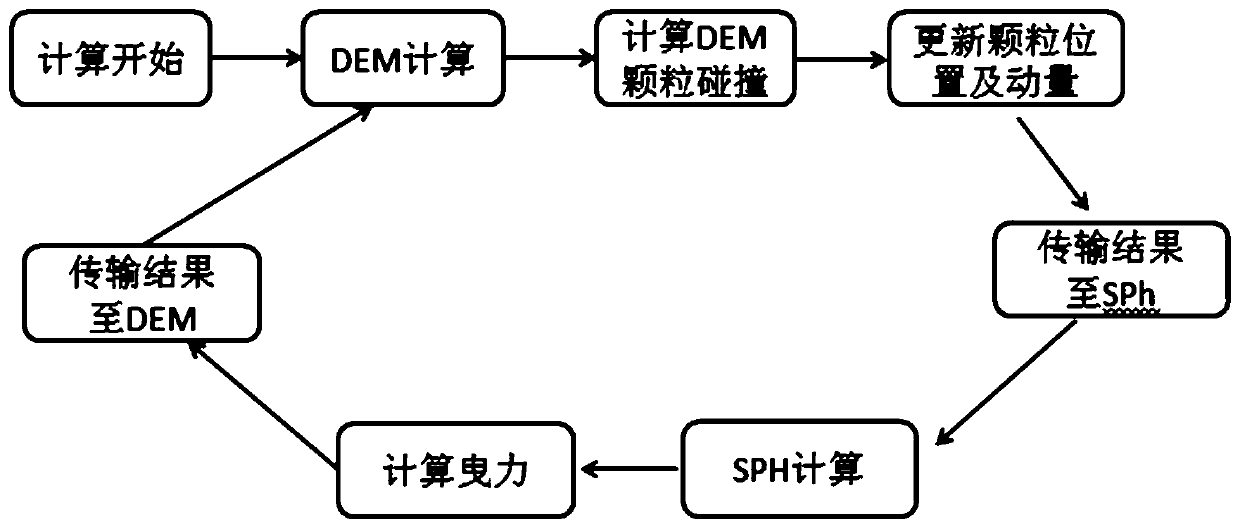

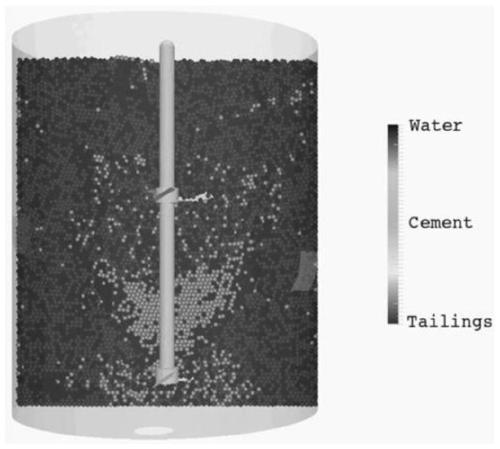

[0071] In an embodiment of the present invention, a high-concentration tailings slurry mixing process optimization method includes the following steps:

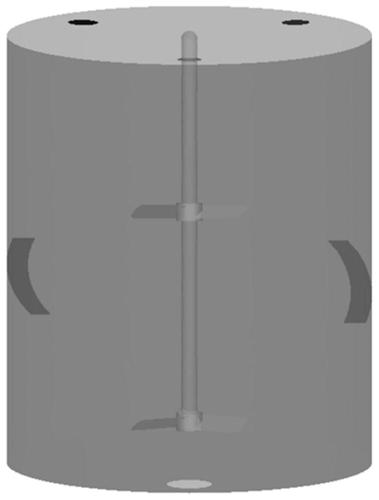

[0072] Step S1. Preliminarily determine the high-concentration tailings slurry mixing process: a mine has a production capacity of 3 million tons per year, and the underflow of the thickener has a mass concentration of 66% and a flow rate of 180m 3 Enter the mixer under the condition of / h; the cementitious material is synchronously added into the mixer according to the lime-sand ratio of 1:10, and the flow rate of the slurry at the outlet of the mixer is required to be 200m 3 / h, mass concentration 68%; according to the effective utilization coefficient of the mixer container 0.7, the mixing time of the material is 3min, the preliminary calculation of the mixer selection is 3.0m in diameter, 2.6m in height; according to experience, a single-shaft double impeller structure is adopted, and each impeller has three fans Blade, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com