Ablation-resistant/bearing integrated air inlet and integral forming method

An integral molding and ablation-resistant technology, which is applied in the field of composite materials, can solve problems such as easy delamination of the interface, low reliability of the air inlet, and complicated molding methods, and achieve simple molding reduction, good process stability, and operability Sexuality, good demonstration effect and the effect of popularizing and applying value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

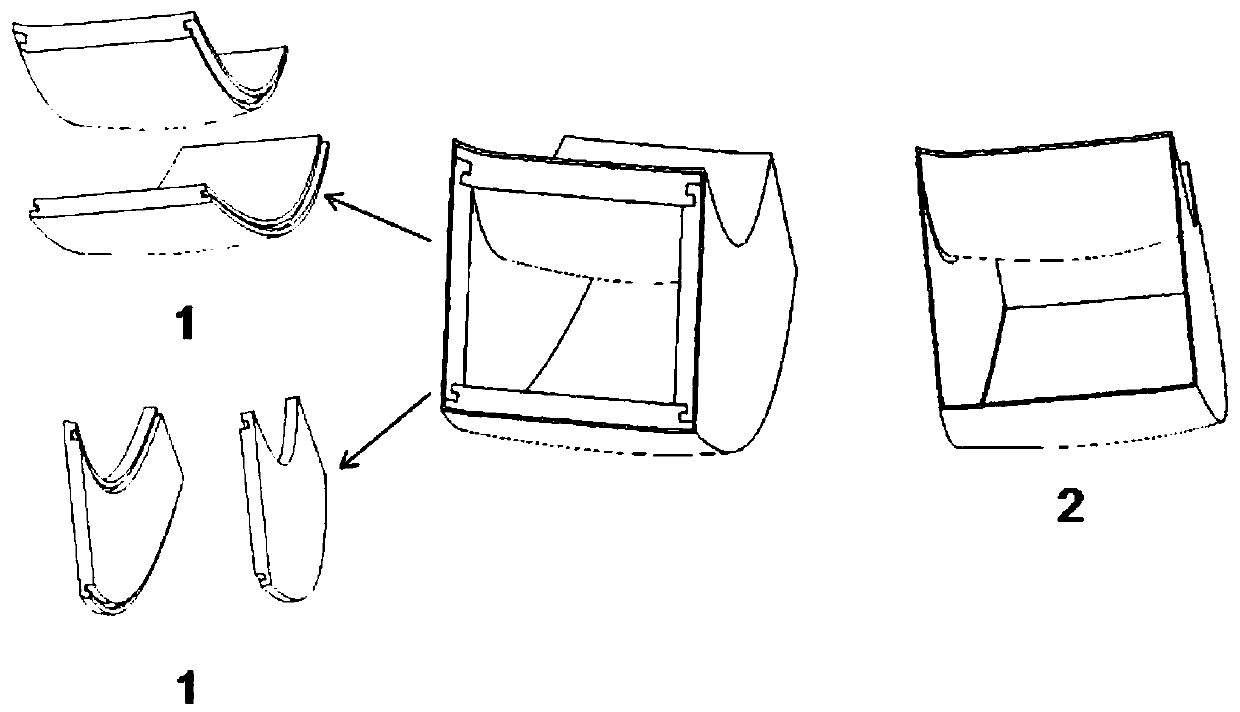

[0050] Make an anti-scouring and ablation-resistant integrated air inlet, the diameter of the largest end is 190mm, the diameter of the small end is 100mm, and the total length is 420mm. Among them, the ablation-resistant layer 1 is a high-silica chopped fiber / aminophenolic premix with a thickness of 5mm, and the bearing layer 2 is a T700 carbon fiber / aminophenolic prepreg with a thickness of 3mm.

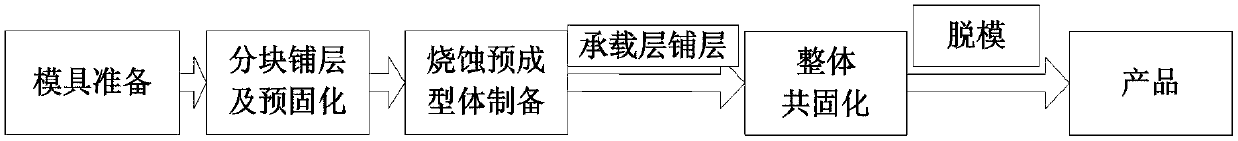

[0051] The specific implementation process of the overall co-curing molding process of the anti-scouring and ablation-bearing integrated air inlet is as follows:

[0052] Step 1: Brush the release agent on the surface of the mold, and lay up layers according to the block plan and design thickness;

[0053] The second step: pre-cure according to the pre-cure process of high-silica chopped fiber / aminophenolic premix, that is, cure at 90°C for half an hour;

[0054] Step 3: For pre-cured molded parts, perform L-shaped lap joints on the male mold according to the design drawings to pr...

Embodiment 2

[0058] Make an anti-scouring and ablation-resistant integrated air inlet, the diameter of the largest end is 190mm, the diameter of the small end is 100mm, and the total length is 420mm. The ablation-resistant layer 1 is a quartz chopped fiber / aminophenolic premix with a thickness of 4mm, and the bearing layer 2 is a T700 carbon fiber / aminophenolic prepreg with a thickness of 4mm.

[0059] The specific implementation process of the overall co-curing molding process of the anti-scouring and ablation-bearing integrated air inlet is as follows:

[0060] Step 1: Brush the release agent on the surface of the mold, and lay up layers according to the block plan and design thickness;

[0061] The second step: pre-cure according to the pre-cure process of quartz chopped fiber / aminophenolic premix, that is, cure at 90°C for half an hour;

[0062] Step 3: For pre-cured molded parts, perform L-shaped lap joints on the male mold according to the design drawings to prepare ablation-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com