Turbocharger volute assembly

A turbocharger and volute technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as limited improvement space, uneven pressure distribution, and increased risk of high-cycle fatigue of turbine blades, and achieve simple manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

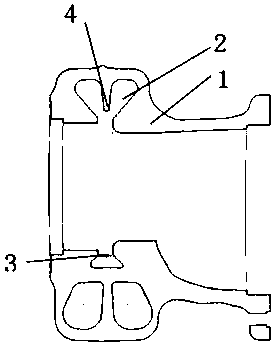

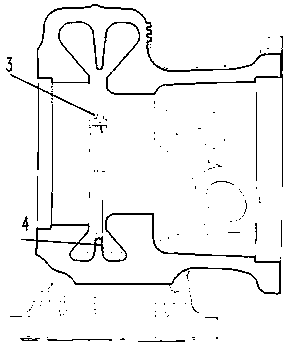

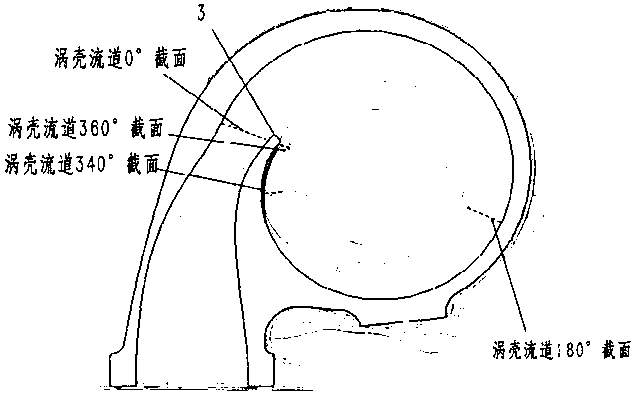

[0016] Figure 1~3 Among them, including volute 1, volute channel 2, volute tongue 3, partition wall 4, etc.

[0017] Such as Figure 1~3 As shown, the present invention is a turbocharger volute assembly, including a volute 1, a volute flow passage 2 is arranged on the volute 1, and the volute flow passage 2 is divided into two separate air intake passages by a partition wall 4, A vortex tongue 3 is provided inside the intake end of the volute channel 2, and the partition wall 4 is a partition structure that maintains separate air intake settings on both sides of the volute channel 2. The height of the partition wall 4 changes with the angle, which is a gradual partition. wall.

[0018] The structure of the transition section of the partition wall 4 starts at any position from 0 to 360° inside the volute channel 2 , and the cut-off positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com