Tail gas treatment device for low-temperature garbage disposal equipment and low-temperature garbage disposal equipment

A technology for waste treatment equipment and exhaust gas treatment, which is applied in lighting and heating equipment, combustion methods, external electrostatic separators, etc. effect of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

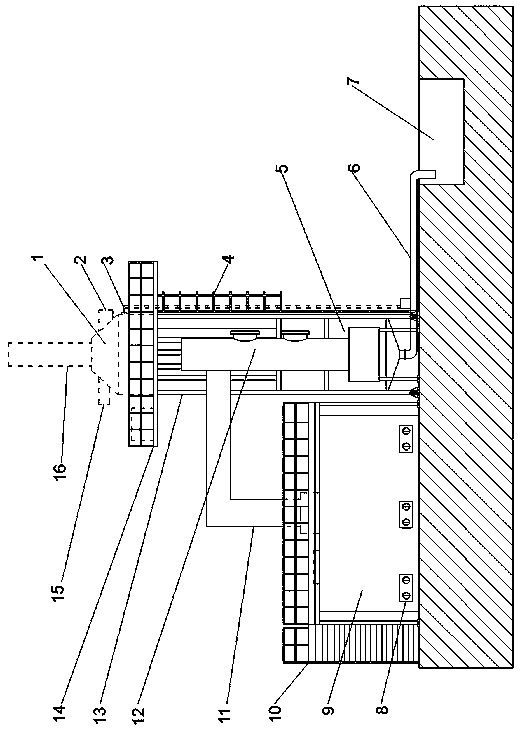

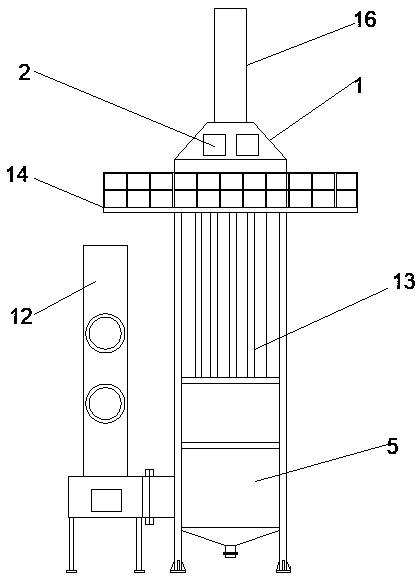

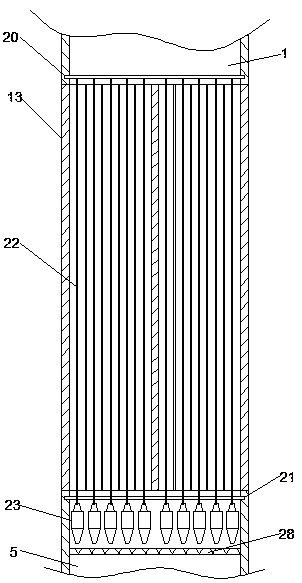

[0026] like Image 6As shown, a low-temperature garbage treatment equipment tail gas treatment device includes a low-temperature decomposition part, a wet dust removal part and an ionization dust removal part. A tail gas treatment mechanism capable of removing carbon monoxide and dioxins in the flue gas is provided on the gas outlet of the ionization dust removal part. The tail gas treatment mechanism includes an operation box 1, a chimney 16 is arranged on the top of the operation box 1, and the bottom of the operation box 1 communicates with the shell 13. Two air blowers 2 are arranged on one side of the top of the operation box 1, and a plasma flame thrower 15 is arranged on the other side of the top of the operation box 1. Adjustable angle is provided with air outlet pipe 19 on the air outlet, and air outlet pipe 19 is arranged in the operation box 1, and the power of plasma flame injector 15 is 10kw, and the flame end of plasma flame injector 15 is connected to the flame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com