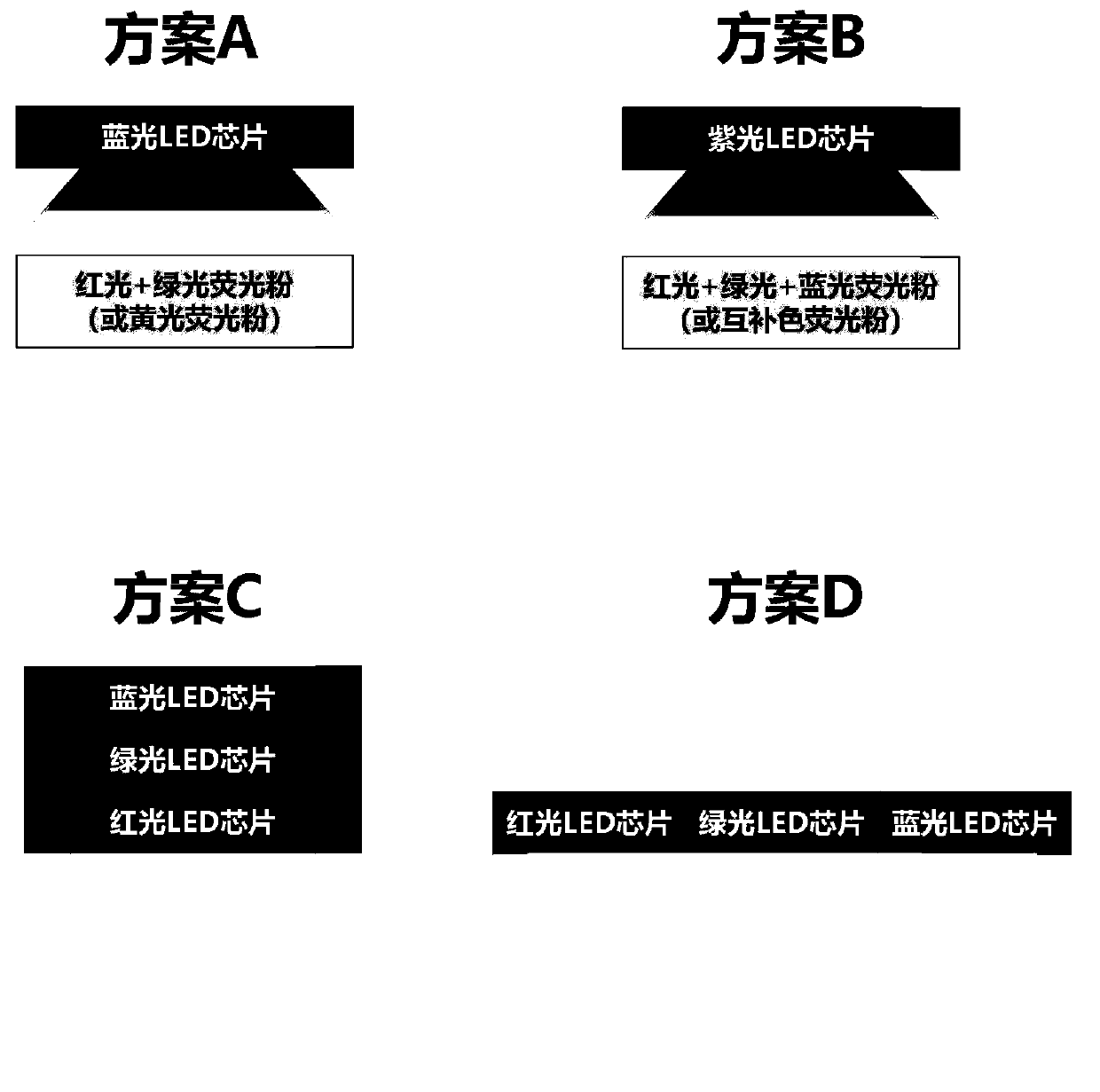

Thin film type white light LED chip

An LED chip and thin-film technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of complex driving circuit design, low efficiency of white LEDs, and complicated device preparation processes, and achieve overall external quantum efficiency improvement. The actual utilization rate and the effect of reducing lighting energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

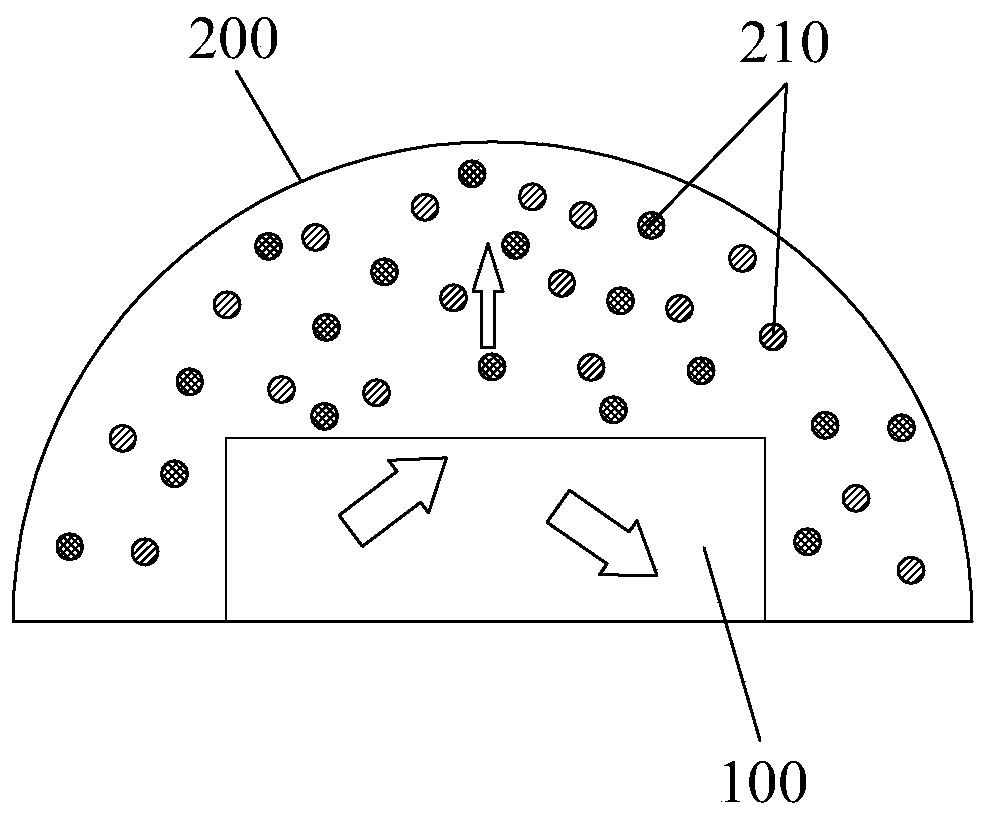

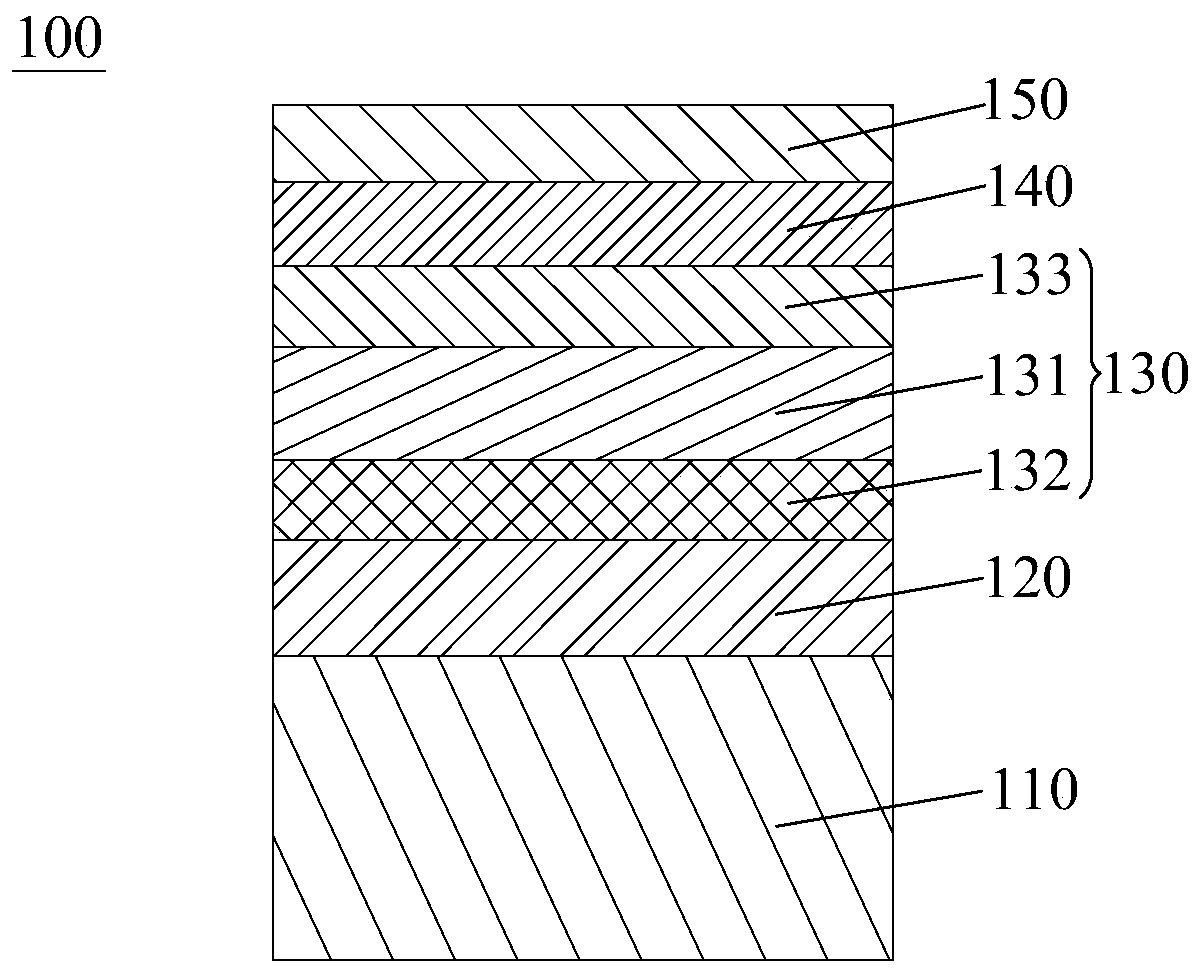

[0036] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0037] Combine first Figure 3a-Figure 4b As shown, the thin-film white LED chip 100 provided by the present invention includes a transparent substrate 110 , a first transparent electrode 120 , a light emitting structure 130 , a second transparent electrode 140 and a first phosphor layer 150 arranged in sequence. Wherein, the light-emitting structure 130 includes a light-emitting layer 131 and a hole injection layer 132 and an electron injection layer 133 disposed on both sides thereof, and the total thickness of the electron injection layer 133 and the second transparent electrode 140 (inverted structure) or hole The total thickness of the injection layer 132 and the second transparent electrode 140 (upright structure) is less than one light emitting wavelength of the light emitting layer 131 (details will be described l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com