Process for increasing liquiritigenin content

A technology of glycyrrhizin and technology, which is applied in the technology field of increasing the content of glycyrrhizin, can solve the problems of high cost, complicated technology, unfavorable large-scale production, etc., and achieve the effect of low cost, broad application prospect and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

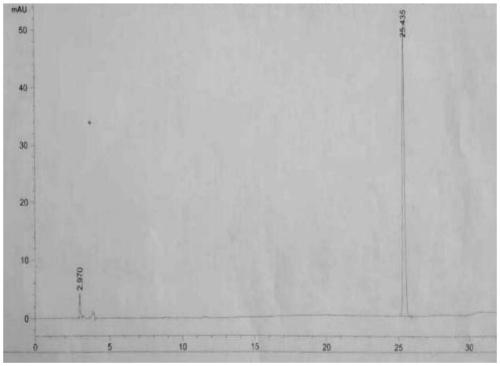

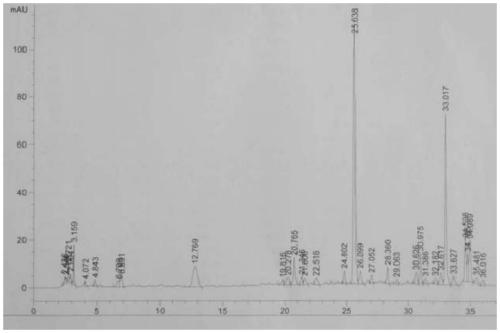

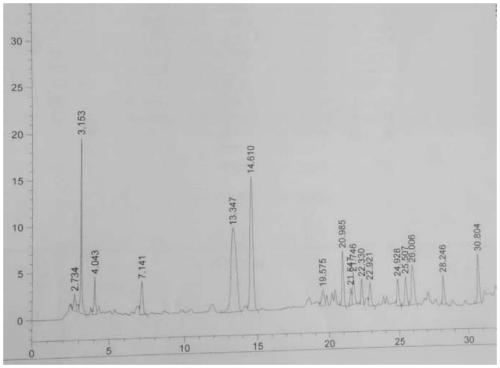

Image

Examples

Embodiment 1

[0030] Embodiment 1, the technology that the present invention improves Liquiritigen content

[0031] Take 10kg of licorice medicinal material, ultrafinely pulverize it to 300-500 mesh, sterilize at 100°C for 30 minutes, add 8g of cellulase, 6kg of sterilized distilled water, and then add 35g of Saccharomyces cerevisiae (purchased from Angel Yeast Co., Ltd.), Mix evenly, put it into a breathing bag, ferment at 25°C for 2 days, and then dry to obtain a licorice fermented product.

Embodiment 2

[0032] Embodiment 2, the technology that the present invention improves glycyrrhizin content

[0033] Take 10kg of licorice medicinal material, ultrafinely grind it to 300-500 mesh, sterilize at 100°C for 30min, add 7g of cellulase, 5.5kg of sterilized distilled water, and then add 30g of Saccharomyces cerevisiae (purchased from Angel Yeast Co., Ltd.) , mixed evenly, packed into a breathing bag, fermented at 25°C for 2 days, and then dried to obtain a licorice fermented product.

Embodiment 3

[0034] Embodiment 3, the technology that the present invention improves glycyrrhizin content

[0035] Take 10kg of licorice medicinal material, ultrafinely grind it to 300-500 mesh, sterilize at 100°C for 30min, add 9g of cellulase, 6.5kg of sterilized distilled water, and then add 40g of Saccharomyces cerevisiae (purchased from Angel Yeast Co., Ltd.) , mixed evenly, packed into a breathing bag, fermented at 28°C for 3 days, and then dried to obtain a licorice fermented product.

[0036] The beneficial effects of the present invention are demonstrated through experimental examples below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com