Gas-phase reaction buffer chamber based on atmospheric pressure microwave plasma torch

A technology of microwave plasma and gas buffer chamber, which is applied in the field of plasma technology and environmental chemistry application, to achieve the effect of increasing chemical reaction rate, increasing plasma density and electron temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

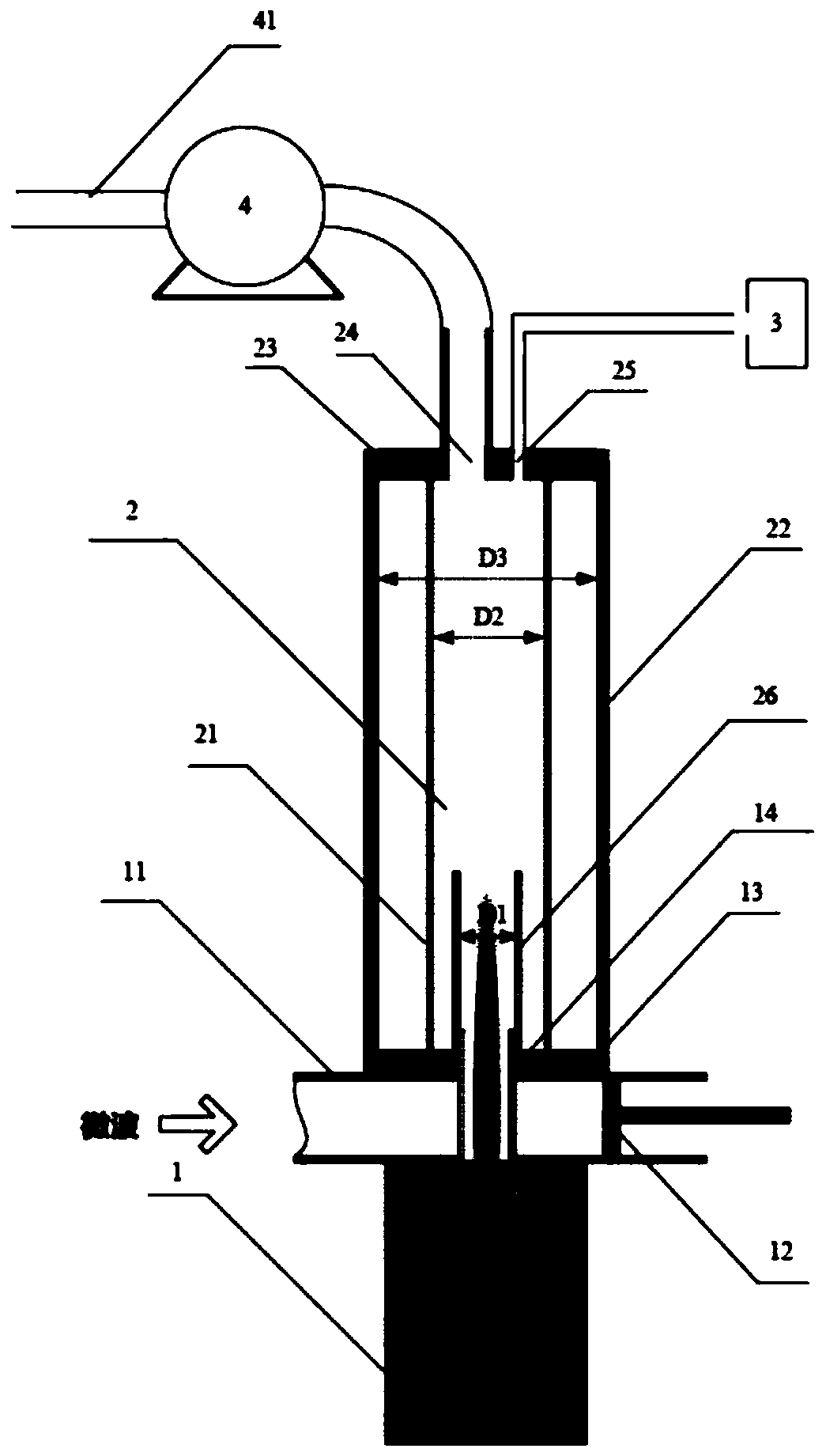

Method used

Image

Examples

Embodiment 1

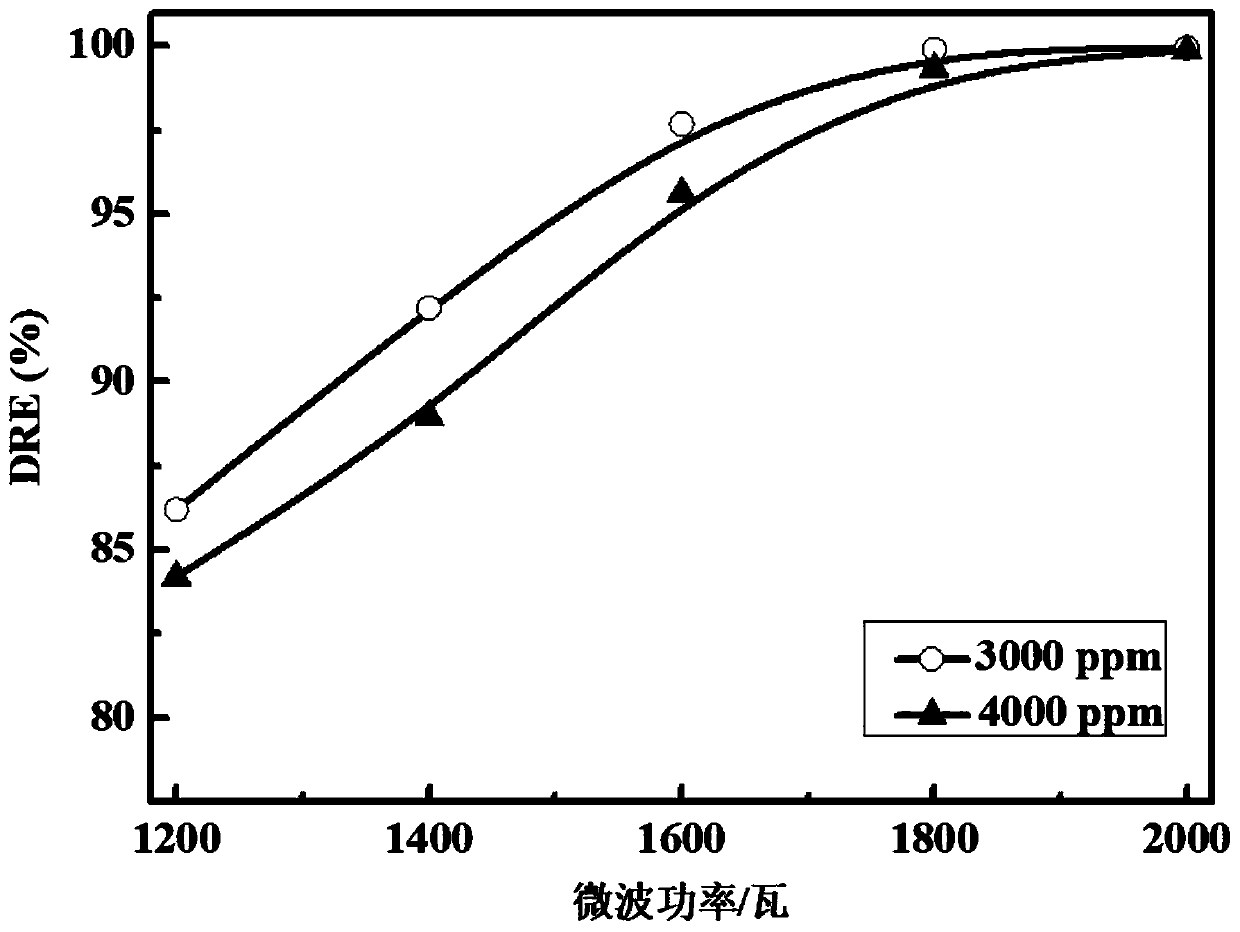

[0039] CF 4 Degradation experimental results. Under the condition of nitrogen as the background gas, turn on the microwave plasma torch, set the gas flow rate to 15 L / min and the microwave power to 1000W, so that the plasma discharge remains stable, and CF is mixed into the plasma carrier gas 4 Gas, the concentration of gas gradually increases from the minimum value to the set value to keep the discharge stable. Measurements are obtained at CF 4 The ratio of mixed nitrogen carrier gas is 3000ppm and 4000ppm respectively, and the total gas flow rate is 15 liters per minute. The degradation rate DRE value changes with the microwave power. The definition method of DRE is as follows:

[0040]

[0041] where C before and Cafter Represent the CF before and after plasma removal obtained from the FTIR spectra, respectively 4 concentration. figure 1 Shown is CF 4 When the concentration is 3000ppm and 4000ppm respectively, the application patent CN207070436U proposes a kind of...

Embodiment 2

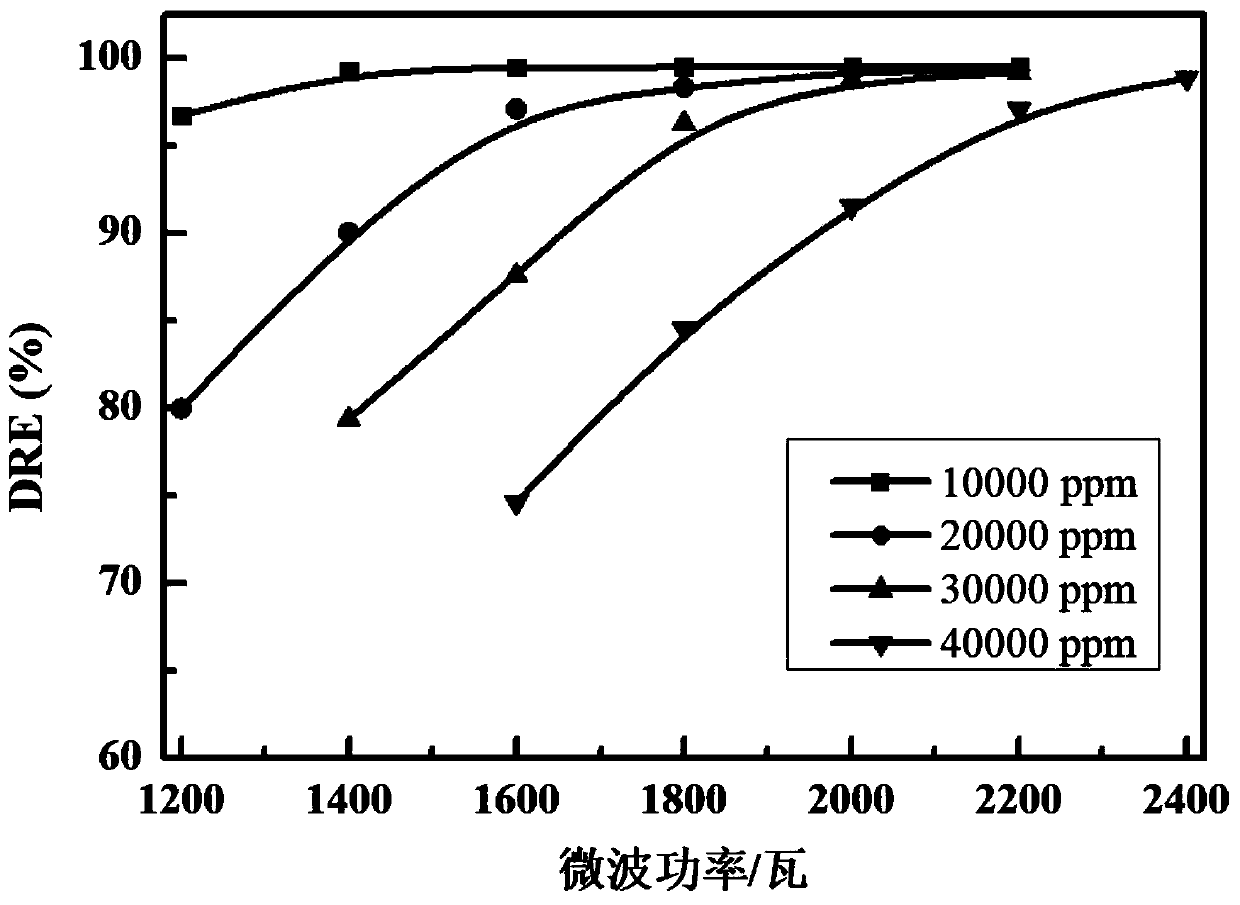

[0043] Application of patent CN207070436U proposed a dual-chamber excited atmospheric pressure microwave plasma torch and the gas phase reaction buffer chamber of the present invention for SF 6 Degradation experimental data. Under the condition of nitrogen as the background gas, turn on the microwave plasma torch, gradually switch from nitrogen to oxygen under the condition of keeping the total flow rate of 15 liters / min, and finally discharge under the condition of pure oxygen carrier gas. Set the gas flow rate to 15 L / min and the microwave power to 1000W to keep the plasma discharge stable, and mix SF into the plasma carrier gas 6 Gas, the gas concentration gradually increases from the small to the set value to keep the discharge stable. Measurements got in SF 6 The ratio of mixed oxygen carrier gas is 10000ppm, 20000ppm, 30000ppm, and 4000ppm respectively, under the condition that the total gas flow rate is 15 liters per minute, the degradation rate DRE value changes with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com