Surface cation functionalized graphene oxide material as well as preparation and application thereof

A graphene and functionalization technology, applied in the field of surface cationic functionalized graphene oxide material and its preparation, can solve the problem of non-enrichment of phosphorylated protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

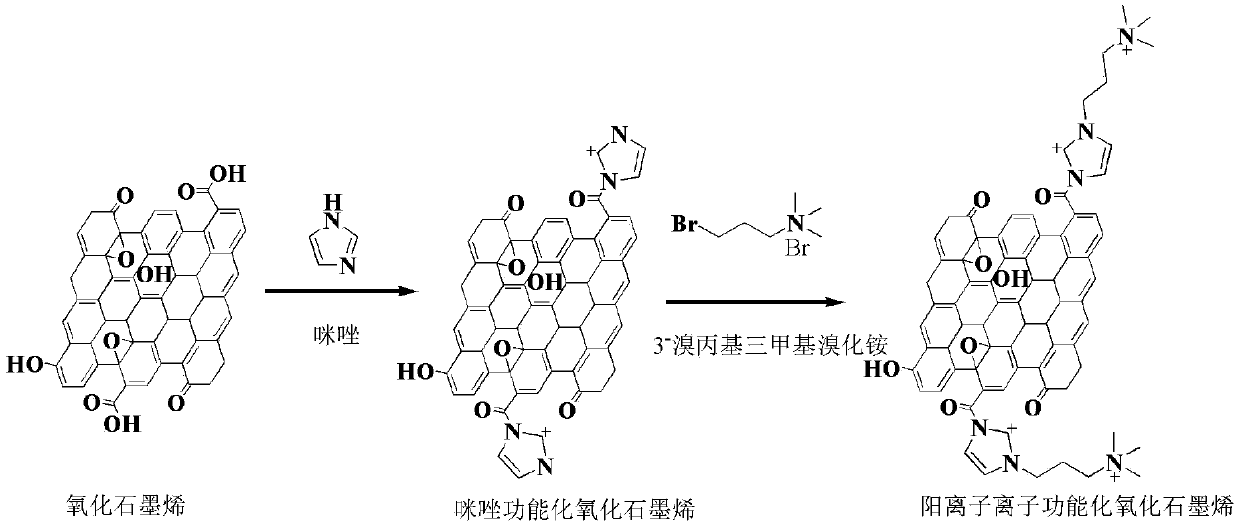

[0016] 1. Preparation of surface cationic functionalized graphene oxide: press figure 1 As shown, 1) Imidazole-functionalized graphene oxide material: using the condensation reaction between the carboxyl group on the surface of the graphene oxide and the imidazole amino group, the imidazole-functionalized graphene oxide material; specifically, a 1mg / mL graphene oxide morphine ethanesulfonic acid solution , Ultrasonic for 2h to completely peel the GO to form a uniform dispersion, then add 1.05g 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) and 627mg N-hydroxysuccinimide (NHS) is used as an activating reagent to activate the carboxyl group ultrasonically for 2 hours. After the activation reaction is completed, imidazole molecules with 10 times the mass of graphene oxide are added, and the reaction is stirred for 180 minutes to functionalize the graphene oxide material with imidazole. The unreacted imidazole and condensation reagent were removed by centrifugation, washed wit...

Embodiment 2

[0021] 1. Preparation of surface cationic functionalized graphene oxide: press figure 1 As shown, 1) imidazole-functionalized graphene oxide material: using the condensation reaction between the carboxyl group on the surface of the graphene oxide and the imidazole amino group, imidazole-functionalized graphene oxide material; specifically, a 2mg / mL graphene oxide morphine ethanesulfonic acid solution , Ultrasonic for 2h to completely peel the GO to form a uniform dispersion, then add 1.05g 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) and 627mg N-hydroxysuccinimide (NHS) is used as an activating reagent to ultrasonically activate the carboxyl group for 2 hours. After the activation reaction is completed, imidazole molecules with 5 times the mass of graphene oxide are added, and the reaction is stirred for 120 minutes to functionalize the graphene oxide material with imidazole. The unreacted imidazole and condensation reagent were removed by centrifugation, and the deioniz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com