Superhigh water-soluble functionalized graphene/oxidized graphene and preparation method thereof

A graphene and water-soluble technology, which is applied in the field of super water-soluble functionalized graphene/graphene oxide and its preparation, can solve the problems of restriction of popularization and application of graphene materials, difficulty in long-term storage, low dispersion stability, etc., and achieve Ease of implementation, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Concentrated sulfuric acid, chlorosulfonic acid and sulfur trioxide are added to the multi-tubular membrane reactor with a mass ratio of 2:3:3, and then commercially available graphene is added to mix evenly, so that the graphene content in the mixed reactant reaches 1wt%. React at a temperature of 60°C for 1 hour, and recover the tail gas with alkaline solution. After the reaction is completed, distill the mixed reactant at 160°C, and wash the residue with water to obtain the target product.

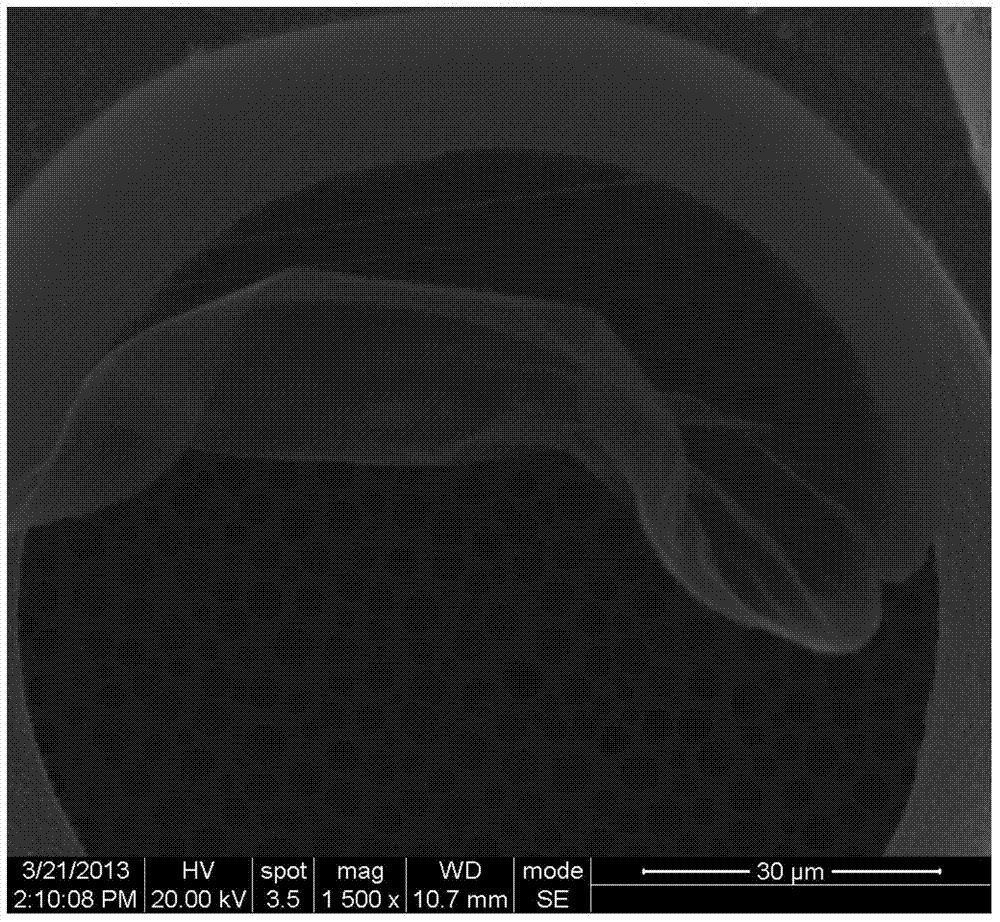

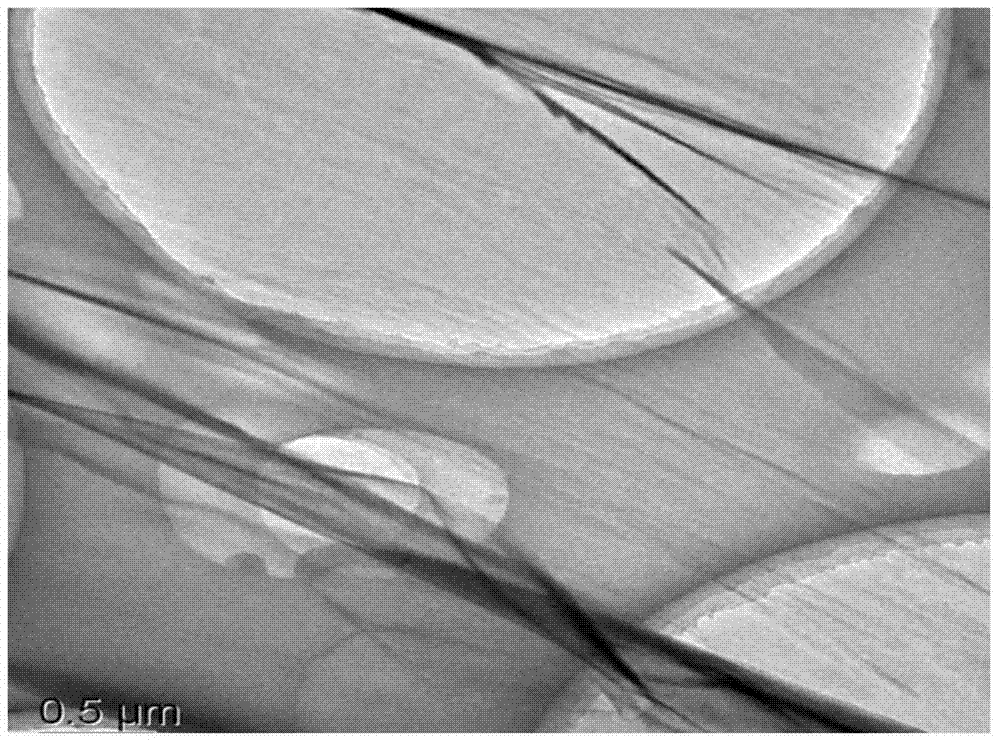

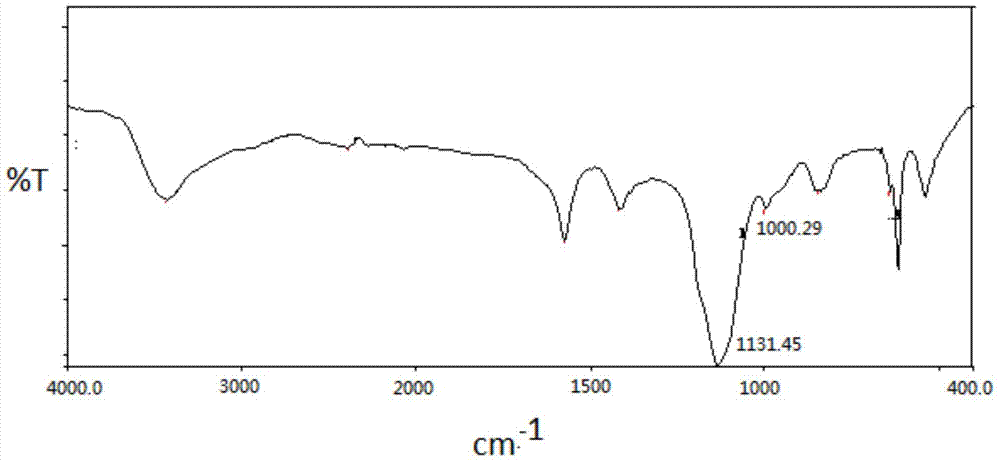

[0025] refer to Figure 1-Figure 2 , observe the target product by TEM, it can be seen that it maintains the film-like structure of graphene and graphene oxide, and then refer to image 3 , through qualitative and quantitative analysis of the target product by IR, Raman spectrum, etc., it can be found that the surface of the target product is connected with a sulfonic acid group (see image 3 , The peaks around 1137 and 1000 are the characteristic peaks of sulfonate ...

Embodiment 2

[0027] Example 2 Add the concentrated sulfuric acid, chlorosulfonic acid and sulfur trioxide to the multi-tubular membrane reactor in a mass ratio of 1:5:3, then add commercially available graphene and mix evenly, so that the graphene content in the mixed reactant reaches 10wt%. React at 150°C for 10 hours, recover tail gas with lye, and distill the mixed reactant at 180°C after the reaction, and wash the residue with water to obtain the target product. Similarly, by observing the target product through TEM, it can be seen that it maintains the film-like structure of graphene and graphene oxide, and then qualitatively and quantitatively analyze the target product through IR, Raman spectroscopy, etc., it can be found that the target product There are sulfonic acid groups attached to the surface of the product, and its mass percentage content can reach 10%.

[0028] When the target product is dispersed in water, the concentration of the obtained dispersion can reach 12wt%, and...

Embodiment 3

[0029] Example 3 Add the concentrated sulfuric acid, chlorosulfonic acid and sulfur trioxide to the multi-tubular membrane reactor in a mass ratio of 1:7:2, then add commercially available graphene and mix evenly, so that the graphene content in the mixed reactant reaches 6wt%. React at a temperature of 100°C for 4 hours, and the tail gas is recovered with lye. After the reaction is completed, the mixed reactant is waited for qualitative and quantitative analysis of the target product. It can be found that the target product has a similar quality to the product obtained in Example 1-2. physical form, and the surface of the target product is also connected with sulfonic acid groups, and its mass content can reach 13%.

[0030] When the target product is dispersed in water, the concentration of the obtained dispersion can reach 15%, and the stable storage time can reach two years.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com