Ship crankshaft polisher

A polishing machine and crankshaft technology, applied in the mechanical field, can solve the problems of no quality assurance, low polishing efficiency, laborious polishing methods, etc., and achieve the effect of good centering effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

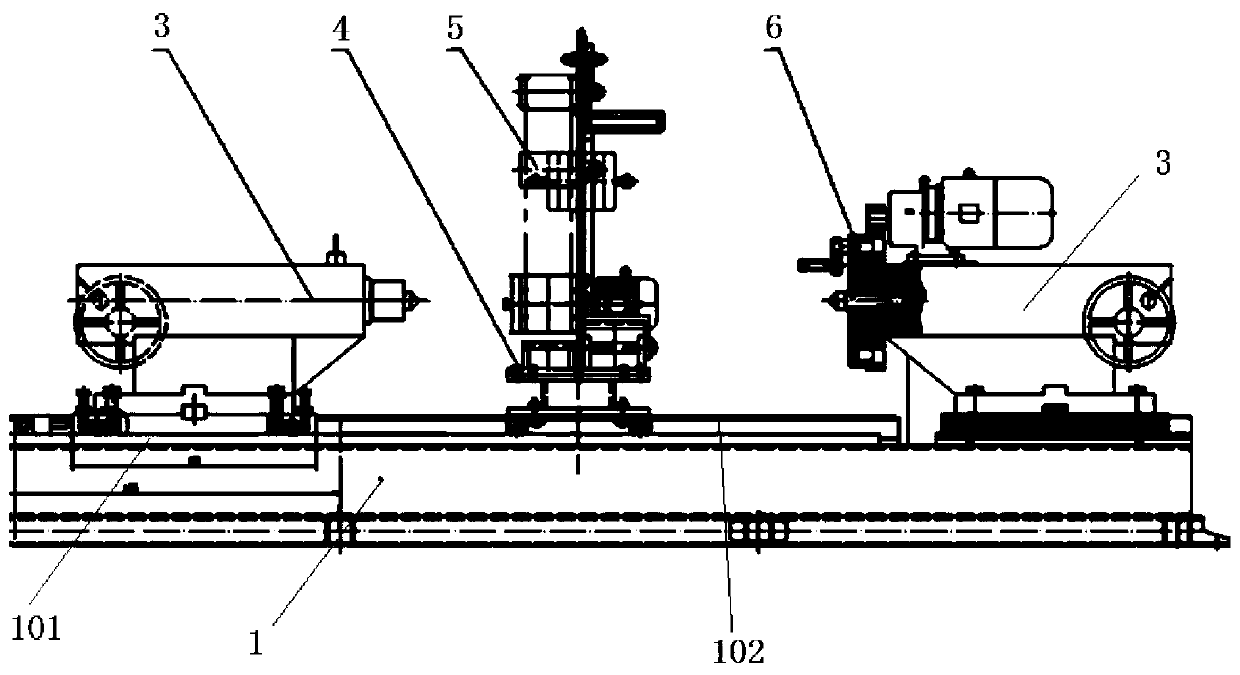

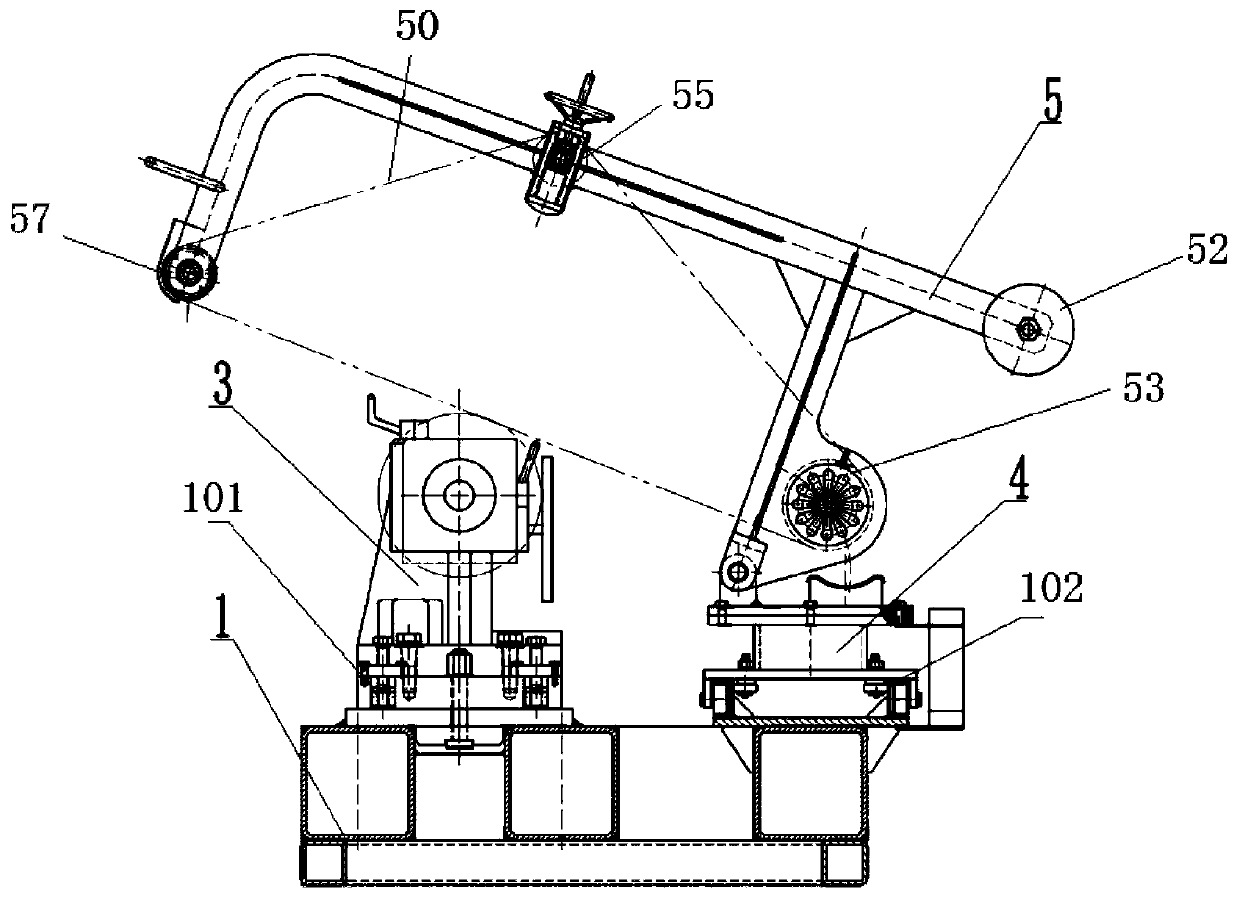

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, the present invention includes a bed 1 on which a first guide rail 101 and a second guide rail 102 are arranged, and the first guide rail and the second guide rail are parallel; one end on the first guide rail is arranged Tailstock moving plate 31, tailstock 3 is fixedly set on the tailstock moving plate, driving device 6 is fixedly set above the fixed tailstock at the other end; mobile platform 4 is set on the second guide rail, and polishing arm 5 is set on the moving platform; Both the tailstock moving plate 31 and the moving platform 4 are provided with stabilizing devices;

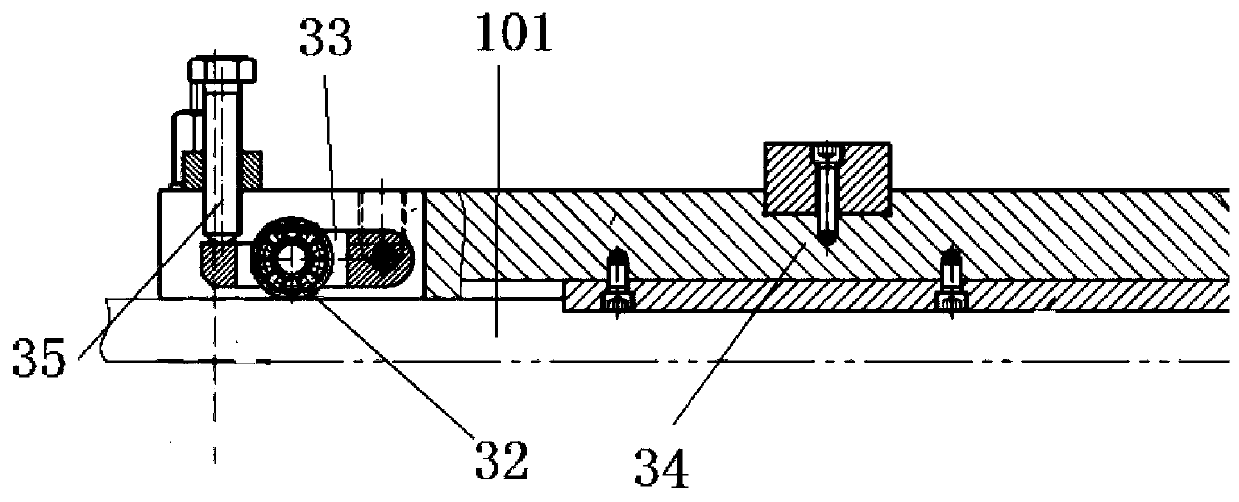

[0032] The tailstock moving plate 34 is provided with a stroke adjustment device, and the stroke adjustment device includes a plurality of sets of bearings 32 rolling on the first track, the bearings are fixed on the bearing support plate 33, and one end of the bearing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com